|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#422 | |

|

Zilvia Addict

Join Date: Feb 2008

Location: The SLC, Utah

Age: 38

Posts: 794

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

thanks for posting that.. +1 |

|

|

|

|

|

|

#423 |

|

Leaky Injector

Join Date: Oct 2006

Location: Southern California

Posts: 66

Trader Rating: (0)

Feedback Score: 0 reviews

|

Hey guys, I found a s13 fastback for sale. its a shell on a rotisery and has already had the seams welded. I understand the work was done by a shop. I was always warned to use caution welding chassis seams for fear of warping. should i avoid this sale or can i inspect it in some way? maybe check the heat "marks" in the metal for how fast/hot/rythem of the welding?

__________________

-Erven -Erven

|

|

|

|

|

|

#424 |

|

Post Whore!

Join Date: May 2006

Location: San Diego, CA

Posts: 9,135

Trader Rating: (19)

Feedback Score: 19 reviews

|

^^^ I don't think you'll be able to tell, one way or another, unless you took frame measurements. In the FSM theres measurements for everything... shock tower-shock tower, etc. If you wanted to spend 30mins in there with a tape measurer, you could put your mind at ease ~

And who doesn't like f*ckin GOLD in their engine bay?!? My god, it just screams 'this car's da bidnezzz' like a top mount manifold or a bay full of stainless lines. "I love gooooooooooooooooooolllllllllllllllllllddddddd..."

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

#425 |

|

Zilvia Junkie

Join Date: Dec 2004

Location: so cal cerritos area

Posts: 432

Trader Rating: (12)

Feedback Score: 12 reviews

|

[QUOTE=driftstyre;1882440]Thanks Jordan!

C&R makes the gold and silver foil that HRP sells. The gold is good but the Silver is a lot better for heat reflection. It is cheaper, a little more weight, but thicker and the adhesive used is better as well (less "stiff" and adheres to contours much better). I have had the firewall lined on the outside and inside with gold foil for two years, but there is only so much it will reflect. I honestly think it is better for hoods, airboxes etc, that can't really absorb much heat. I got some silver to cover the firewall "more better"(I've always wanted to say that) Bill your right, I did my whole firewall and exhaust underside under drivers side feet area as well as covered the oem heatshields in all the gold foil stuff. I think the fiberglass backed stuff should work a lot better. Im still getting my feet hot while at crusing speeds...The fiberglass backed stuff should work A LOT better. |

|

|

|

|

|

#426 |

|

Zilvia Junkie

Join Date: May 2006

Location: deutschland

Age: 35

Posts: 483

Trader Rating: (1)

Feedback Score: 1 reviews

|

i am trying to teach myself how to weld, so is it possible that i post a pic of some welds and you tell me what i do wrong or what i can do better?

here are the pics:  and the backside:  edit: oh yea it's 1.2mm stainless steel 2nd edit: thats mig welded Last edited by Jakob; 03-21-2008 at 11:24 AM.. |

|

|

|

|

|

#427 |

|

Zilvia Member

|

can't find my glasses right now, but is that mig or tig?? if tig, you're going too hot and WAY too much filler. start low on your amps and increase as necessary to maintain a decent weld puddle. if fitment is perfect, no filler is required and you can just fuse them. try to only have 90% penetration to keep contamination from the back of the weld down. i would try starting at 40 amps, smallest tungsten you have ground down to a SHARP point, and use .030 or .035 filler (unless you have access to smaller).

|

|

|

|

|

|

#429 |

|

Zilvia Member

|

if you post what types of settings and welder setup it will be easier to give you more direction. the weld technique is a pretty good start. but yeah needs less heat and less filler.

|

|

|

|

|

|

#430 |

|

Zilvia Junkie

Join Date: May 2006

Location: deutschland

Age: 35

Posts: 483

Trader Rating: (1)

Feedback Score: 1 reviews

|

the welder itself is a cheap unit, so i cant really adjust the settings. there are 2 switches i have put them both at the lowest setting (you can switch from 1 to 2 and from min to max) i had them at min and 1. the filler adjuster is a scale from 1 to 10 i had it between 3 and 4. i used 1mm thick filler. its a mig welder and i used argon with co2

|

|

|

|

|

|

#431 |

|

Leaky Injector

Join Date: Mar 2007

Location: Midwest City, OK

Age: 36

Posts: 68

Trader Rating: (0)

Feedback Score: 0 reviews

|

this thread is awesome! i love it. got a few questions for some of you. i am looking at getting a new welding rig. i really don't need anything crazy or fancy, just something with all around abilities. its going to be a descent mig set up. so far i have been looking at the century 140gs or the hobart 210. any input would be appreciated on if this is a quality set up. i pretty much plan on using it for chassis/cage work, and probally exhaust and sheet metal work.

|

|

|

|

|

|

#432 |

|

Leaky Injector

Join Date: Oct 2006

Location: Southern California

Posts: 66

Trader Rating: (0)

Feedback Score: 0 reviews

|

This is a great book, and well worth the $20 it costs. "Performance Welding Handbook" You can find em in many bookstores and ofcourse online.

__________________

-Erven -Erven

|

|

|

|

|

|

#433 | |

|

Zilvia Junkie

Join Date: Sep 2006

Location: Regina, SK

Age: 34

Posts: 541

Trader Rating: (6)

Feedback Score: 6 reviews

|

Quote:

Go and get some thicker metal, probably about 1/8" would be good, and just practice running beads on it. When you start getting better, move on to butt welds, corner welds, tee welds, lap welds, edge welds just to get used to welding different joints. After that you can try the same welds in different positions (vertical, horizontal, overhead if you want) Looks like you're off the a good start though. Keep at it. Steve

__________________

1997 240sx SE 1998 Frontier SE 1990 240sx Coupe - Sold 1992 Talon Tsi - Sold |

|

|

|

|

|

|

#434 |

|

Zilvia Junkie

|

hey guys,

well i finally got around to do some practicing today on cast aluminum. I felt like chopping up a honda manifold (not sure which motor it was for, but it was for scrap) and welding it back together. Here it is when it was one piece   here are the runners i chopped off one by one     Then of coarse it needs to be cleaned, i used this 2 year old purple power that was sitting around in my garage for ever, i swear this stuff works like magic  all the pieces cleaned inside and out where the area of welding will be     Then it was time for beveling each edge      here are the welds i did for the flange to runners, I tried tack everything up with the manifold and runners and flange, but dam it was getting annoying trying to hold everything and using stuff to hold it, then you realize a tack broke and you go back to fix it and another one breaks, while your trying to align the holes, it just turned into one big mess, so i said f**k it, ill just weld the runners and flange first, i mean after all its just practice. i brushed with stainless steel brush first, then welded.           Not the best looking but i think im getting better, here are some pics i did months ago for cast aluminum, this was the last time i practiced on cast aluminum. Just some stringer beads, and FYI these pieces of cast aluminum is from nissan, belonged to a rb26 oil pan. seems like the aluminum from honda is easier to weld on then the aluminum from nissan, oh well i dont know...     took longer to prepare than to weld, was the only time consuming part. |

|

|

|

|

|

#436 |

|

Zilvia Addict

Join Date: Feb 2008

Location: The SLC, Utah

Age: 38

Posts: 794

Trader Rating: (3)

Feedback Score: 3 reviews

|

^^i am not a expert, but i am pretty sure tig is the only way to PROPERLY weld aluminum

haha.. weld that bitch back up and sell it.. you could probably get some stupid fuck to pay ya 100 for it sayin its "custom". haha |

|

|

|

|

|

#437 |

|

Zilvia FREAK!

Join Date: Aug 2006

Location: Illinois/California

Age: 34

Posts: 1,114

Trader Rating: (13)

Feedback Score: 13 reviews

|

referring to that.. it seems like you dont have anybeads and your getting close to getting it too hot. and like everyone else said that metal is thin..and extremly hard to weld, basically if your doing that, have really fast hands ha.

but it looks okay just no beads.so you can "zig-zag",or try and make your wrist circle fast. good job on welding on that thing stuff though ha ------------------------------------------------------------------------------------------------------------------------------------- i am trying to teach myself how to weld, so is it possible that i post a pic of some welds and you tell me what i do wrong or what i can do better? here are the pics:  and the backside:  edit: oh yea it's 1.2mm stainless steel 2nd edit: thats mig welded |

|

|

|

|

|

#438 |

|

Zilvia Junkie

|

yes it is tig, i forgot to say what process i used. thanks, i am planning on welding the manifold to the runners today.

hehe, i was thinking the same thing, some one might buy it just because it looks custom with the welds on it. |

|

|

|

|

|

#439 |

|

Zilvia Addict

|

DisEpyon: Very nice welds, i know cast is difficult but you definatly make it look good. I wish i could weld aluminum like that. I need to build my intake manifold soon.

__________________

R34 NEO POWER |

|

|

|

|

|

#441 | |

|

Zilvia Junkie

|

Quote:

what is the manifold you are going to make going to go on, and the plans for it too? what is the manifold you are going to make going to go on, and the plans for it too?thanks, the machine i am using is a lincoln precision tig 225 a pic when it was new  |

|

|

|

|

|

|

#442 |

|

Post Whore!

Join Date: Dec 2002

Location: Campbell, Ca

Age: 41

Posts: 5,010

Trader Rating: (3)

Feedback Score: 3 reviews

|

Haha. We have the same welder pretty much. Mine is the older 185. I use mine everyday and have no problems with it for 3 years. Great machines.

Heres mine when new.

__________________

|

|

|

|

|

|

#444 |

|

Zilvia Junkie

|

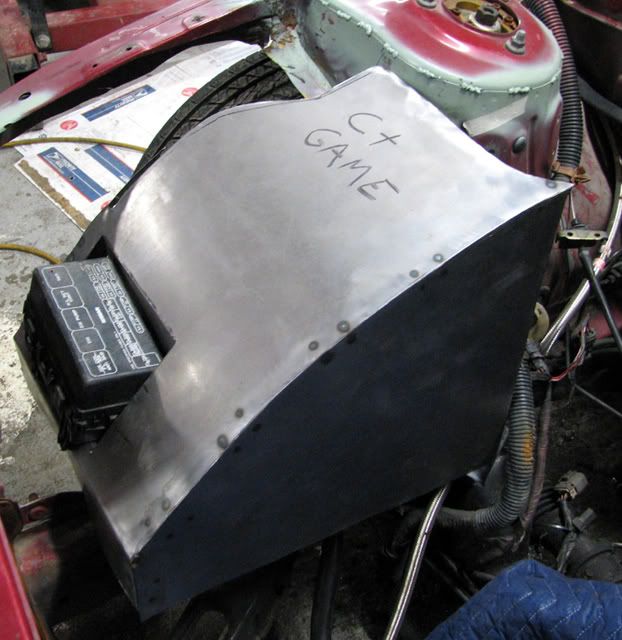

here is something i made for my car awhile back, its a breather ventilation tank or what ever you want to call it.

sorry i dont have any before pics, just the finish product.       so far i dont have any problems yet, car runs good, and still havent loss alot/any of oil, what the dip stick is reading anyways. |

|

|

|

|

|

#445 |

|

Post Whore!

Join Date: Dec 2002

Location: Campbell, Ca

Age: 41

Posts: 5,010

Trader Rating: (3)

Feedback Score: 3 reviews

|

o shit that breather tank is amazing. Any specs on the material and machine settings? it looks as if you oversized the pieces to be welded together, then just fuzed everything with no filler. that is what I do sometimes when I want really small even beads.

__________________

|

|

|

|

|

|

#446 |

|

Zilvia.net Advertiser

Join Date: Apr 2003

Location: Dayton Ohio

Age: 42

Posts: 545

Trader Rating: (4)

Feedback Score: 4 reviews

|

here are a few of the wheels tubs i had shown in the build stages earlier in this thread.

some of the progress just so you dont have to go back pages    Don't mind those seam welds, they are not mine, the owner of the car did those. you can also see where someone had cut the fender supports in half, the whole nose of this car has been chopped off and replaced due to a wreck, i got it pretty close to straight again after the hack job a body shop had done, but its still fits fenders and the hood wierd.

__________________

http://www.forcedfabllc.com/ |

|

|

|

|

|

#448 |

|

Zilvia.net Advertiser

Join Date: Jul 2003

Location: Boston

Age: 44

Posts: 748

Trader Rating: (4)

Feedback Score: 4 reviews

|

Just a few updates. Been working on the front end, and am confident about the way it is working out now. Its far from completion but will hold the intercooler, oil cooler and most importantly, house the four mounting points for the splitter bird cage.

|

|

|

|

|

|

#449 | |

|

Zilvia Junkie

|

Quote:

i fitted the plates with a corner joint, like in example c in the picture, then grinded the edges a tad bit to help give it a bevel  I have a question for those of you that weld on stainless steel alot, how are you guys setting up your back purge system? details or pics would be nice. my brother bought some sch 10 manifold tubing material for me to practice on and im having a little trouble as to how to hook one up. Ive heard people using a seperate cylinder, or hooking up a y splitter some where on there machine or cylinder and running a hose off one end. |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|