Quote:

Originally Posted by scytheSLO

Hi guys,

i'm planning a setup for my forged SR20DET and would like to know what kind of HP can be expected and maybe if anyone has any dyno graphs from running a similar setup (atleast the same turbo)?

Forged rebuilt SR20DET engine (8.5:1) with ported head

FMIC, 3" full exhaust system with no cat

264/264 cams (No vtc)

SS bottom mount manifold

gtx2867 0.86 @ 1.6-1.8 bar

ID1050cc injectors

ecu link G4

I was told by a tuner that it should be good for about 360hp, isn't that a little too much stuff for a HP figure that close to what stage 3a puts out?

|

1. that compression/bottom end is for 500-600hp on pump fuel

If you are using E85 or E50~ blends the compression should be 9.5:1 instead

2. If this is the compressor map

https://www.garrettmotion.com/wp-con...p-GTX2867R.jpg

It looks to be about 450bhp capable at 2.0L

so around 400rwhp seems possible through OEM 5-speed.

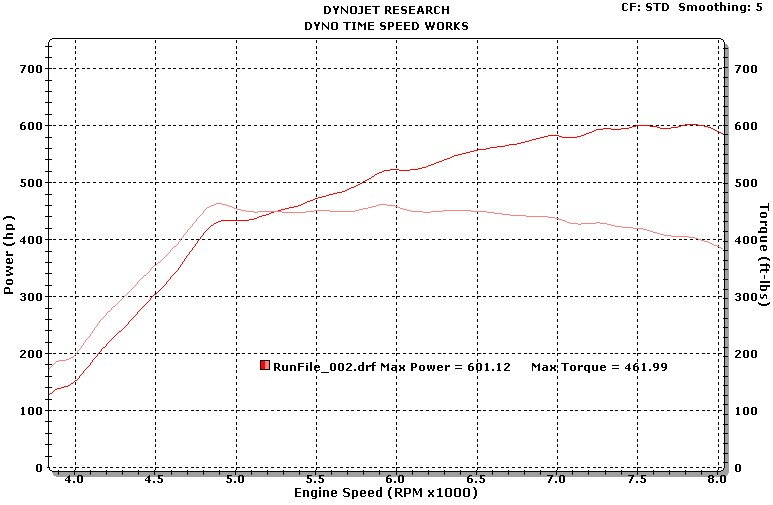

3. As long as the compressor is in typical efficiency ranges, the "type" of turbo won't affect power much. So we can examine other graphs and get an idea of flow rates and power, for example:

18psi on a factory head should give a solid 300ft*lbs of torque

If you can keep 18psi and compressor flow rate up all the way to 7000rpm, you get 400rwhp:

Notice how fast the horsepower drops from 400tire to 360tire, All it takes is +/- ~25ft*lbs of torque at 7,000rpm because:

300*7000/5252 = 399rwhp

but

275*7000/5252 = 366rwhp

the lower power setup has a stronger onset of torque (Expected). The car might even be faster because of that, despite being almost 40hp lower.

That peak number at the far end of the graph is really useful for all-out racing (usually drag racing) where maximum rpm is always used.

Whereas street cars don't want or care for 7,000rpm pulls constantly. They'd prefer to be in typical stoplight ranges, 3k-5k perhaps.

With 2.0L the "small" turbos for daily drivers still tend to wind up 4500+

The best setup I had was this

Full 18psi around 4,000rpm from a $450 top mount T3 50 trim journal turbo on a no-name log. It held 300ft*lbs till 6,600 out of breath.

The point of all this is to mention a couple things

A. torque is based on boost pressure and having

NO BOOST LEAKS is essential for getting every last scrap of power out of a setup, when it 'runs out of breath' every leaked out air molecule counts against it

B. when a turbo 'runs out of breath' the torque/power starts falling off, can be seen clearly on the dyno when it happens, so a turbo not only sizes to engine power desired but also has to match up to engine flow rate at peak RPM which for some engines can be 8,000 or 9,000rpm.

C. for street cars, trade top end power for speedy torque (spool) onset (give up the last 600rpm of worth of torque for a boost) used to be a big issue, a controversial topic. However, 2019 rules: Nowadays turbo tech has gotten good enough that spool isn't as big of an issue anymore. I would simply choose a larger turbo for reliability (as weird as it sounds) because it guarantees that whenever the turbo is 'working' it will be very efficient (safer, cooler air) and that will stress the intercooler less and overall safer with cheap fuels and will make more power with similar torque onset. And also it will be able to 'turn up the boost' later and not have to worry about running out of breath.

Final thoughts

8.5:1 is better matched to a 8,000rpm engine setup making 520-580rwhp (650-700bhp)

If the goal is merely 400rwhp then the compression should be 9.5:1 or at least 9:1

The lower compression makes the car feel lazy out of boost, driving around.

pretty sure I've seen a 2.15L @ 36psi with 8.5:1 compression on straight 93 octane making like 580rwhp before:

https://www.evolutionm.net/forums/ev...l-project.html

93 octane *ONLY*

It gets full boost 4,700rpm, over 400ft*lbs of torque. Using the proper manifold you can have this (400ft*lbs) at 4,700rpm or you can use the smaller turbo and get (~300ft*lbs) of torque at 4,600rpm... see what I am saying... you don't really 'gain' much by using a small turbo these days

And having low compression defeats the purpose of using low boost and having a forged piston.