I have some updates, a lot has changed. I had to move to a new shop, so that took some time to get set up. I was starting to get the ball rolling on everything, but then I got really sick and it wouldn't go away for months. Turns out I have cancer. Stage 4 Hodgkins Lymphoma. I started treatment in October and things are going well with that so far. I'm not working anymore, so I have a lot of free time to finish this build off. I plan everything on the days I feel like poop, and actually work on it when I feel good. Chemo treatments are every 2 weeks and I average about 4 good days before I chemo the fuck up again.

My excuses aside, heres the actual update:

This is where those triangular things go on the forward mounting points on the subframe. I had to rebuild them. Used angle iron and welded a nut to the backside.

Rocker sheet metal replaced, it was nasty inside:

Gotta replace that sheet metal I cut out.

Getting better, 18ga cold rolled.

Got a new tig torch

Driver side rear wheel arches. Its much worse then this.

Rear floor behind driver seat, fixed.

Making a mess uggggg this **** sucks!

Vacuumed!

Front floor in front of driver seat, fixed.

Just enough room for my little ass to get under there.

Got these jammies while I was droppin a deuce

OEM five lug! I have all four + rear bearings!

Took me a while to track this down. I have one on order somewhere else since last year but oh well.

Also, the last remaining parts to put the RB back together. Tensioner, idler, and spring. Again, these were on order, but they failed to come in within a year. SMH!

Going back together. I'll have some significantly better pics of the motor after it goes back in for the last time.

This happened. The car was hung so the entire bottom could be cleaned, primed and painted.

This was done with Raptor sprayed out of a 1.8mm tip on a HVLP gun. Raptor is a 2k truck bed liner that is normally sprayed from a larger tip. It is a 2k product, so we know it will last. Epoxy primer was used as the undercoat, all seams were sealed with the 3M 2k seam sealer after primer, but before the top coat.

Primed, my friend Brandon spraying the topcoat. What a nice guy.

Lovely.

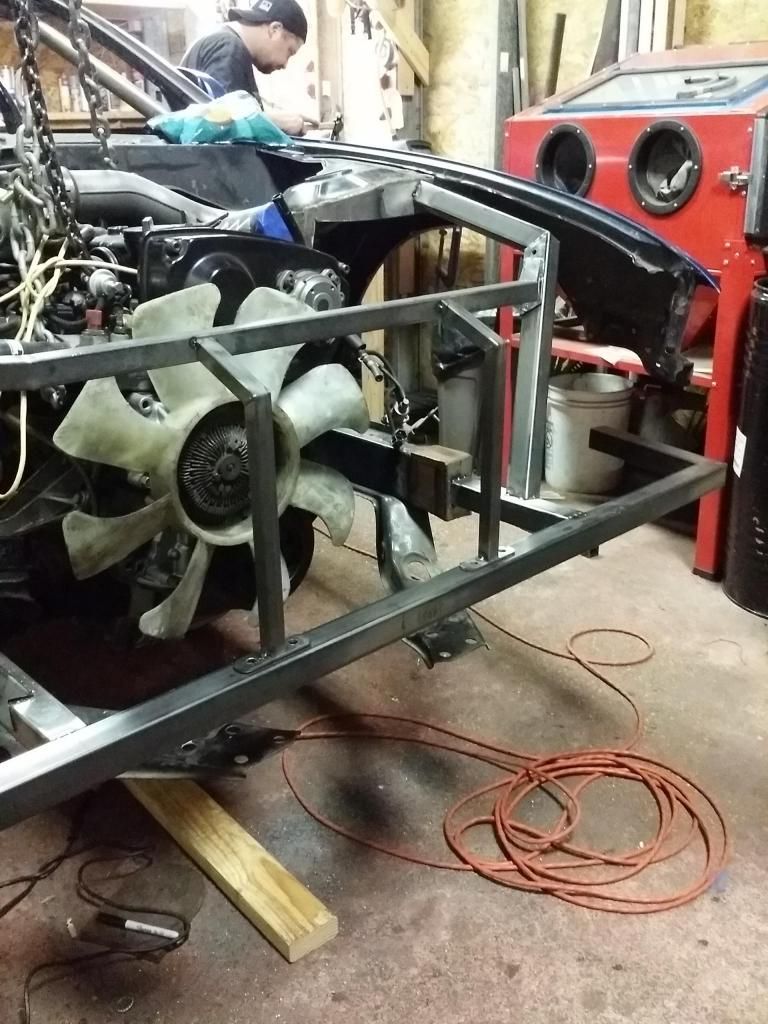

Test fitting of the engine.

I decided I no longer like the first front end I made. Started on a new one. Stan gave me a deal on proper fitting fenders and a bumper, which was a life saver.

Everything is designed to unbolt for easy removal of everything!

Sandblasted the rear LCAs and knuckles. They need to be painted yet.

Picked up these sparco seats for a good deal, and started making brackets for them, its very hard to keep the seats low in this car. Installing these before the door bars is the best bet, that way everything fits.

Progress on the cage. Pretty much the entire cage besides the door bars fabricated.

Door bars almost finished. Preload son. Preload.

Finished up. Taking a break.

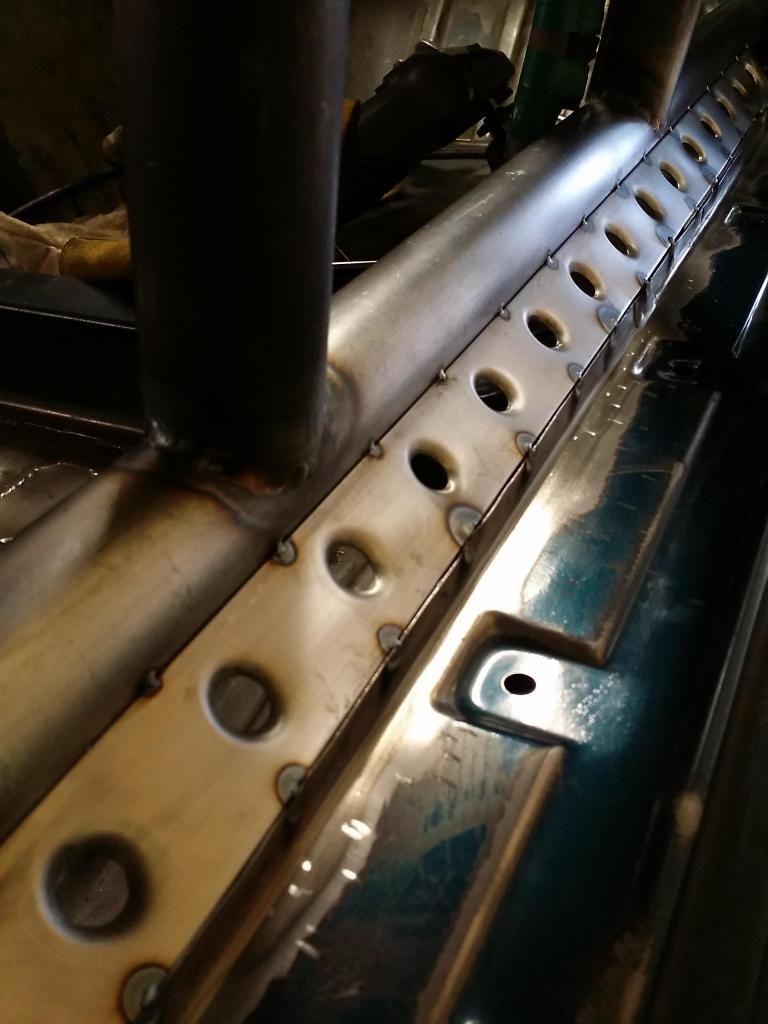

Dimple plate.

Door sill dimple plate.

Moarrr dimple plate.

Steering wheel mount.