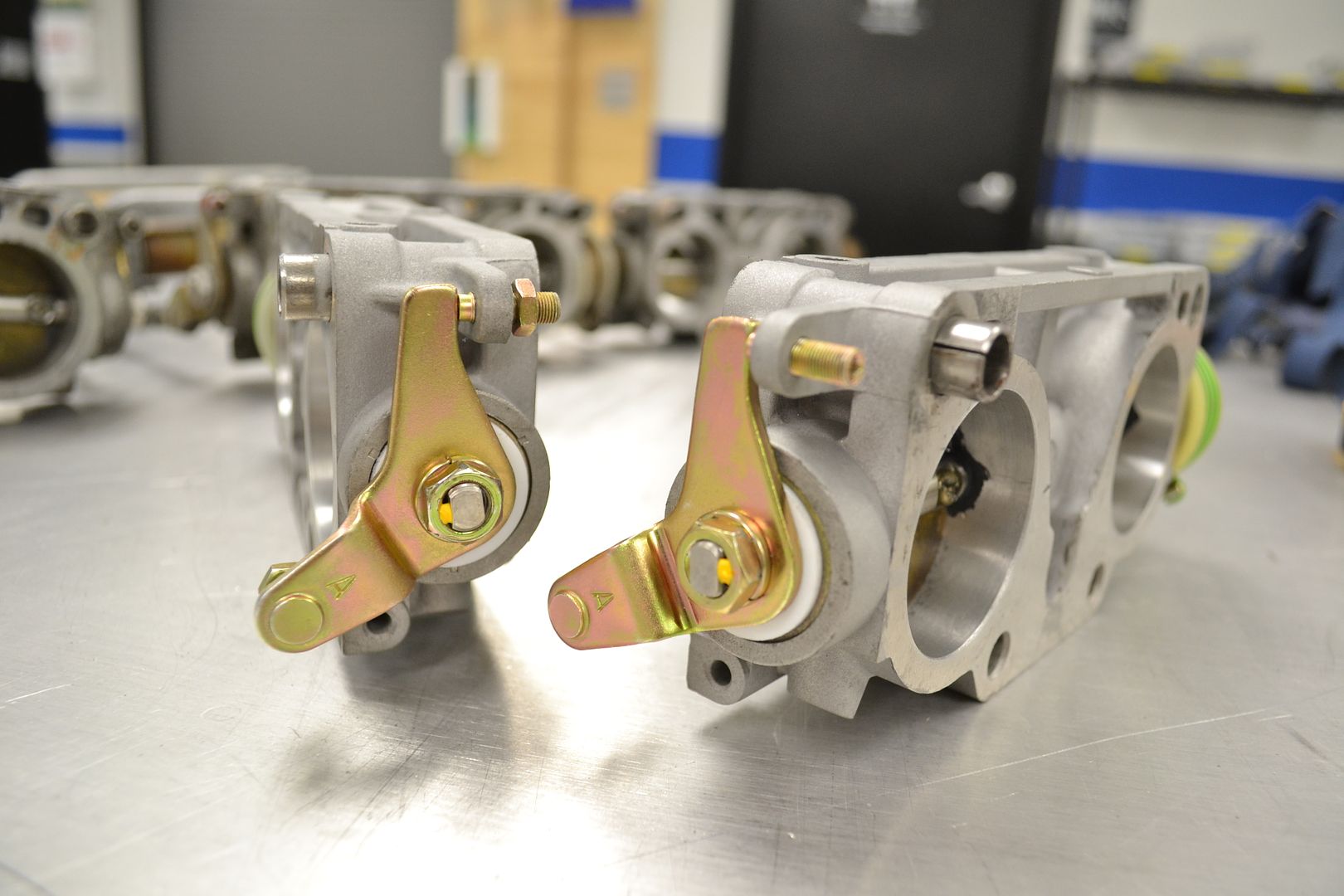

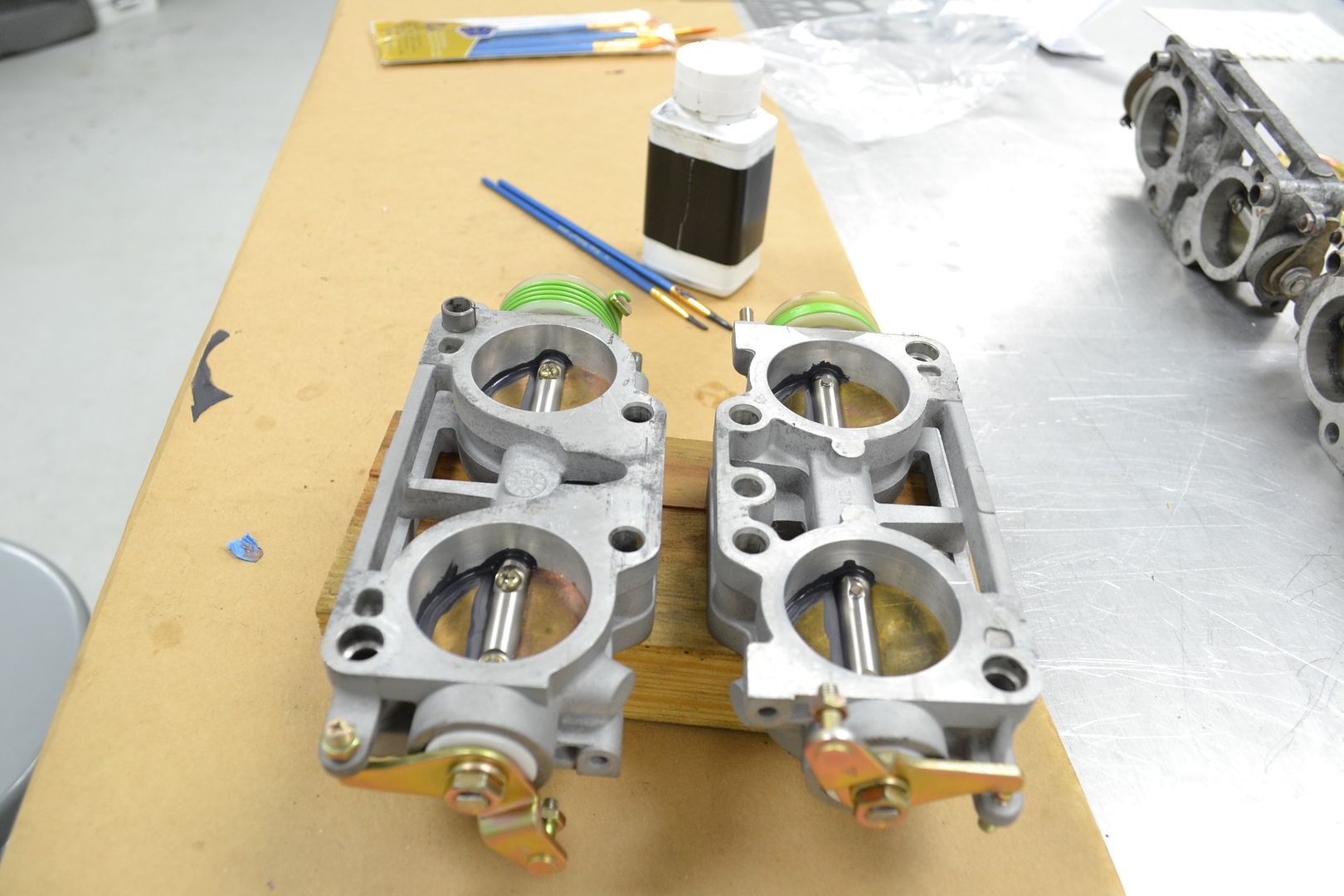

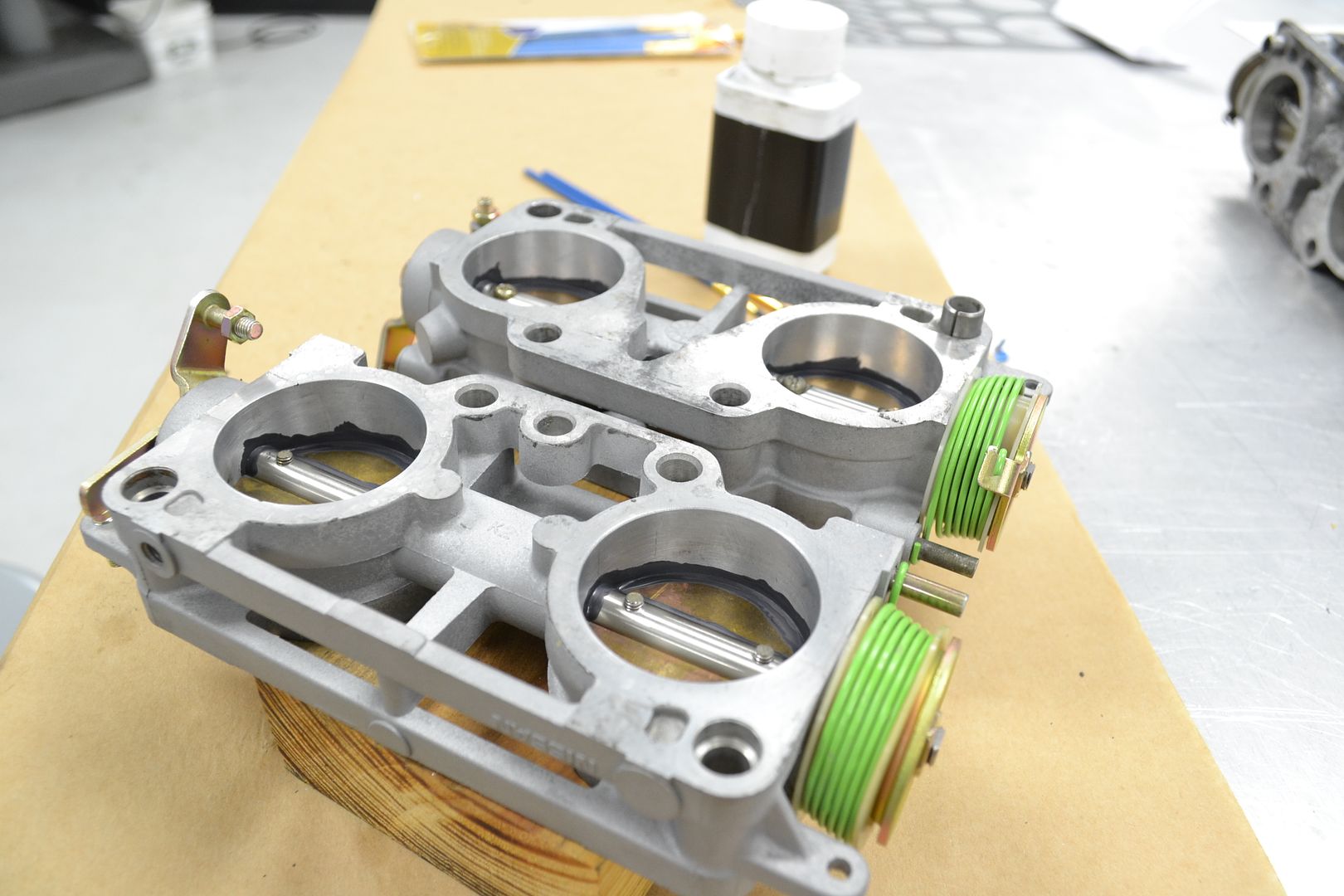

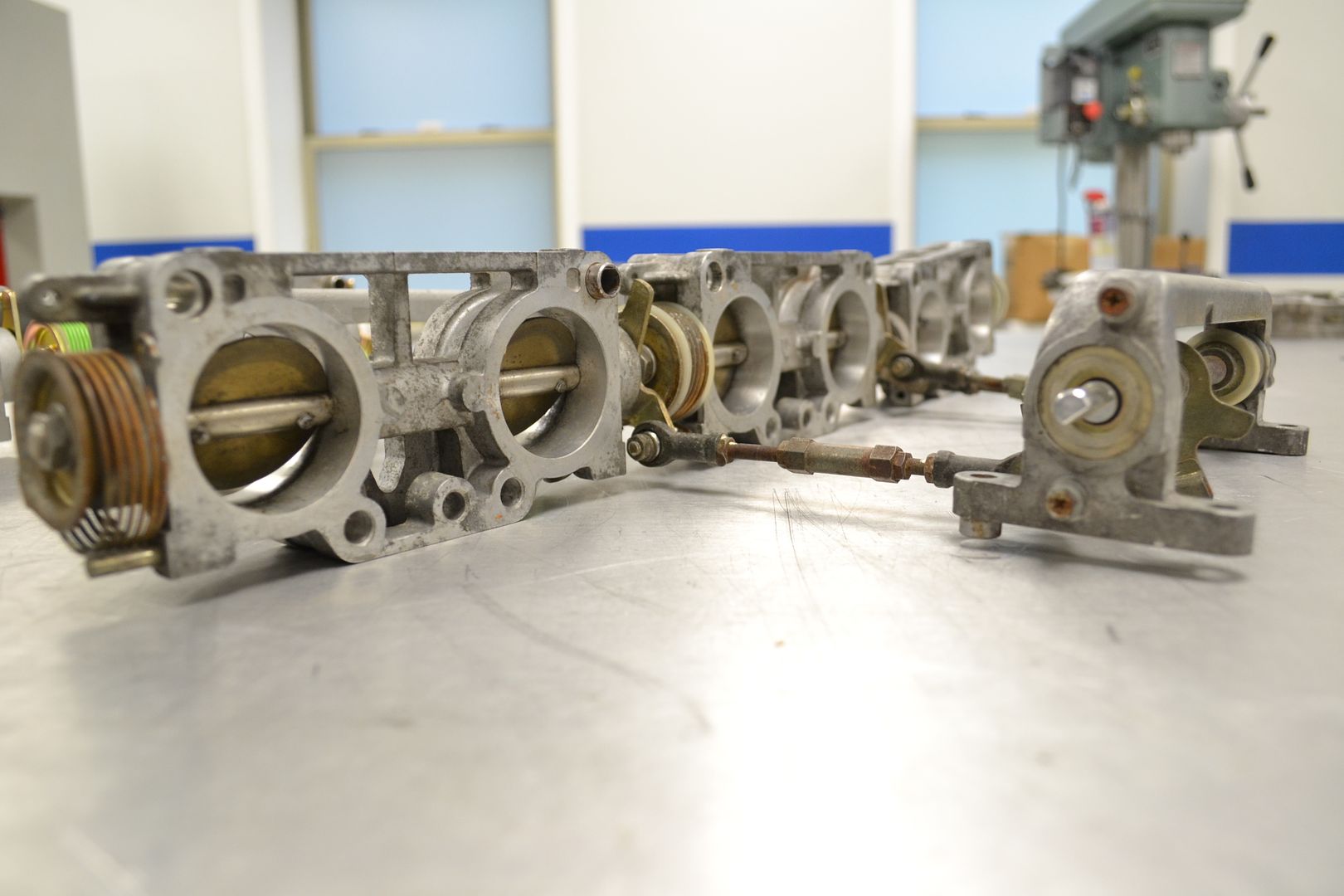

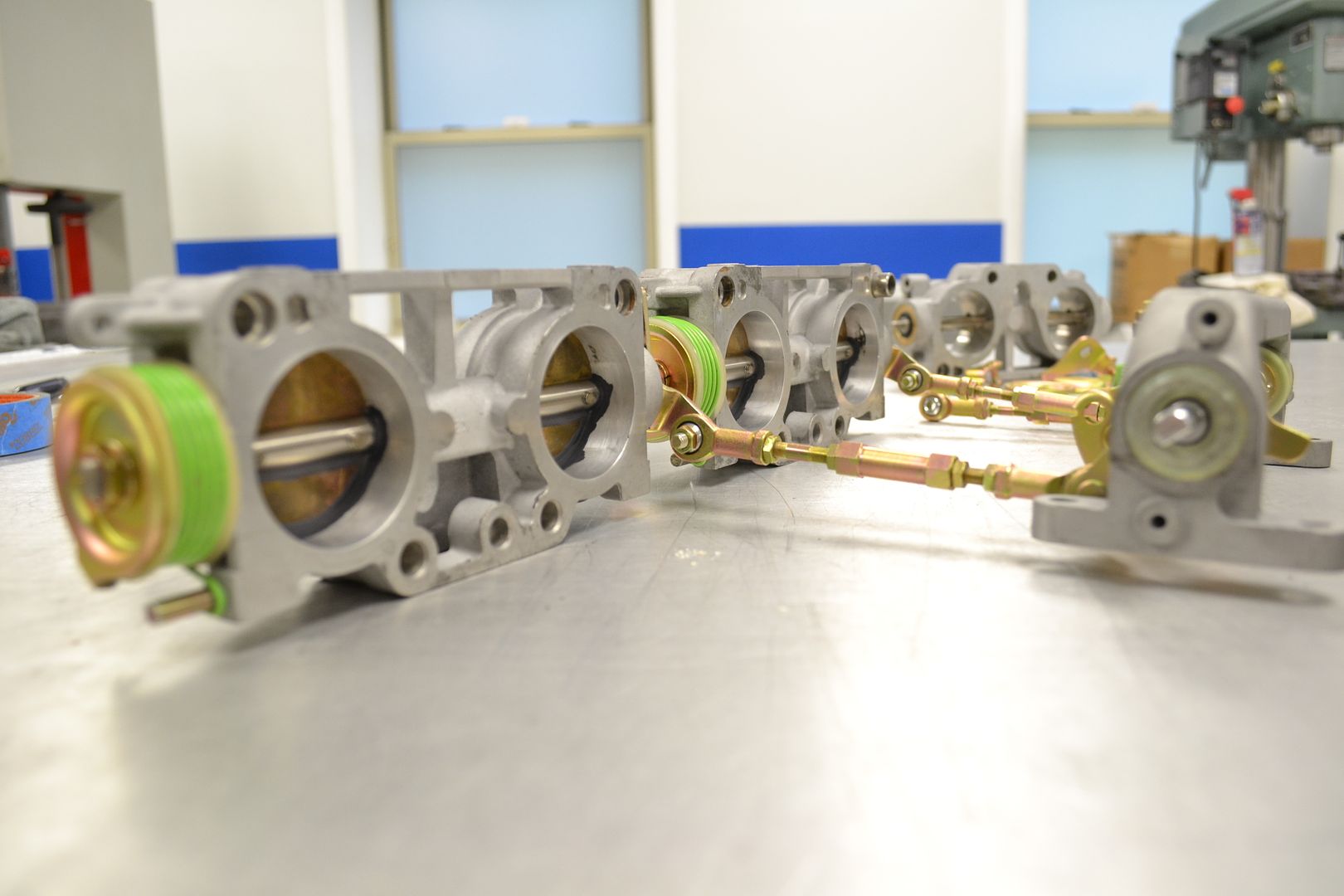

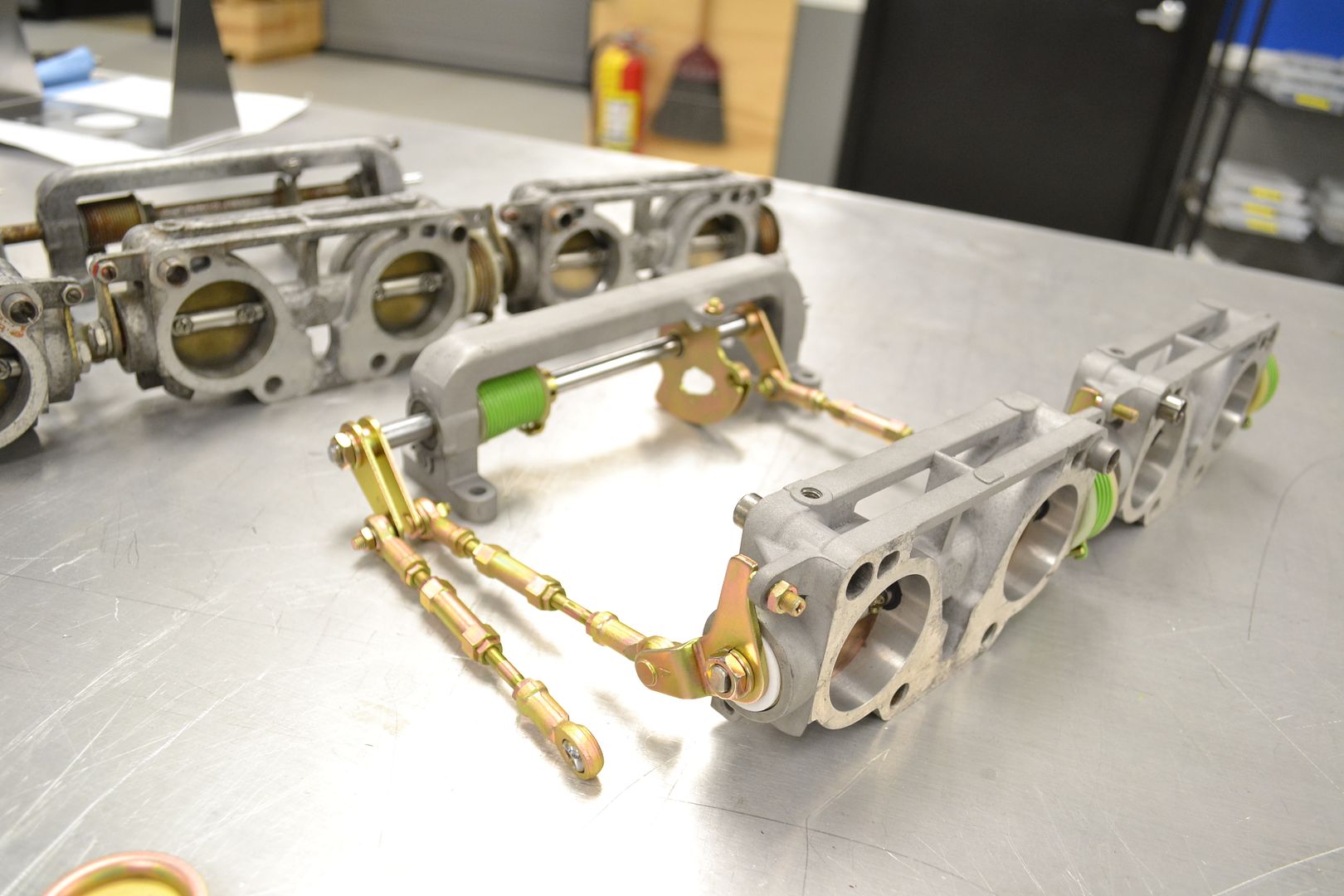

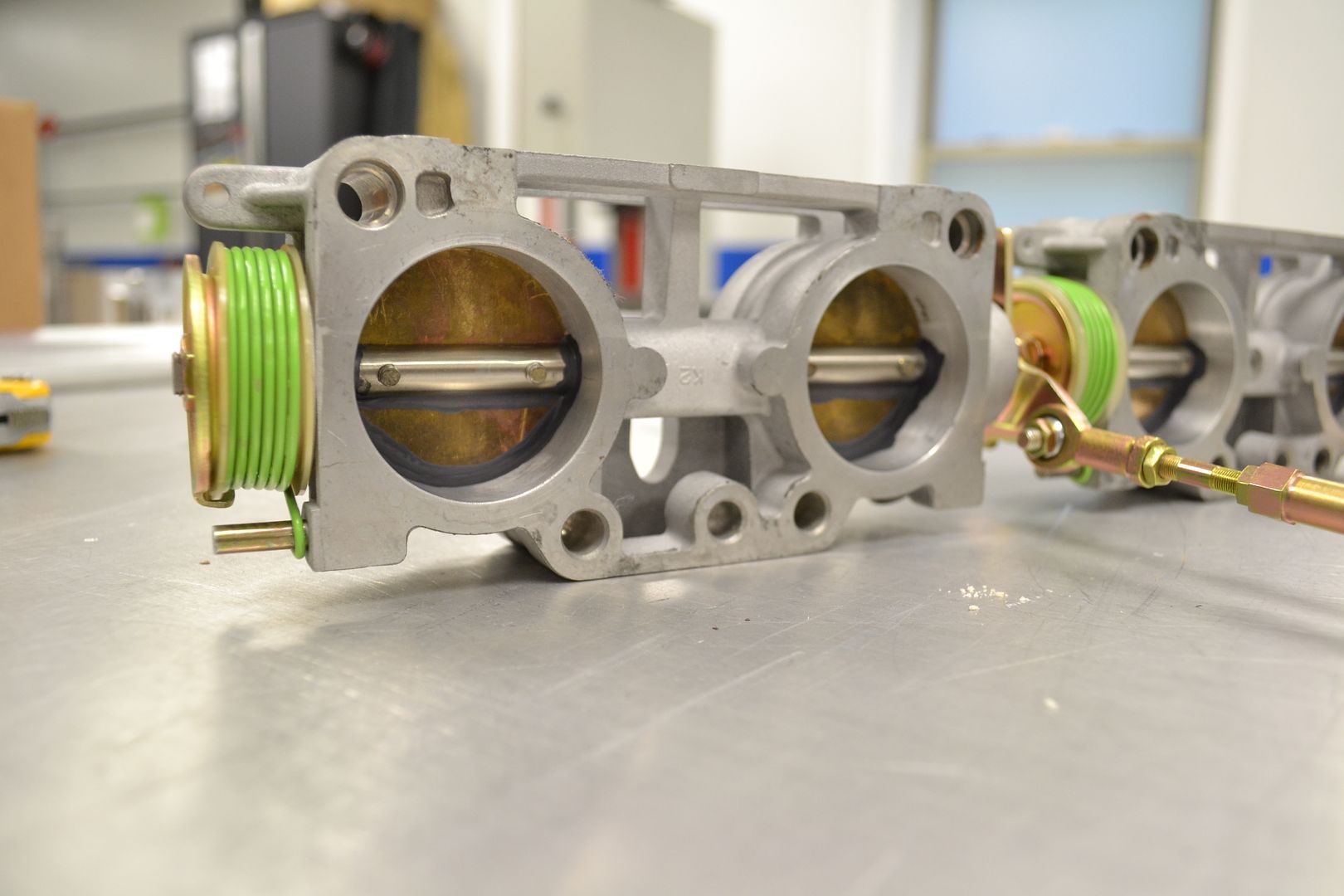

The housing were easier to get apart, but require a lot more prep work to be able to media blast, as there are cavities you definitely don't want glass bead in. Be very careful if your going to do this, as some these components are directional, and it can get very confusing if you don't have a second set to look at. There is no manual for this. The springs were media blasted and painted with an aviation paint we use frequently at work. It is resistant to almost anything a car can throw at it, aside from maybe brake fluid. The spring guides are very fragile, and are usually broken, but I was able to salvage enough for the engine. Luckily, because they are very thin and would hard to machine. The shaft seals were replaced, which were not easy to find, and per the suggestion of another member, machined Delrin washers were installed between the linkage and the seal. This helps to ensure that the seals do not back out under high boost. I couldn't find Nylon washers as the member suggested, so they had to be made. The Delrin has excellent properties for this purpose and puts almost no drag on the linkage as it actually isn't sandwiched in there, there is a tiny pit of play. I thought that was a very clever suggestion from that member, which I have never actually seen done. After they were assembled, the topic of the throttle coating needed to be addressed. This has been talked about before and it is said to be the source of a lot of high idle issues due to there being gaps around the throttle plates allowing too much air to bypass at idle. You can sometimes see this coating left over from the factory, but it is many times mistaken for carbon buildup, and cleaned off, thus creating the issue. The test is usually to hold it up to the light, and check for light bypassing the plate. After installation, I actually did not see a lot of light past the plates, however accumulatively, those slight gaps create a sizable bypass of air. The fix here is the apply an air dry moly coating, sometimes called Dry Film Lubricant. Tomei sells this stuff as "throttle coat", however it is nearly impossible to get from them, from my experience. Not big deal, as this is stuff is not new, and is available if you look. Fortunately, this is another hazardous substance we use at work. Its terrible stuff, likely why its so hard to ship. I am sure there are a number of ways to apply, but I can only comment on how I applied it. It gets brushed on and drys pretty fast. I applied it to both sides of the throttle plate, on the opposite sides of the plate rotation. This areas around the shaft where it enters the housing were coated too. Before it dried completely, I cracked the throttle a few time, allowing it to snap back pretty aggressively. This was to ensure the coating did not crack off in sections once its hard and brittle. The result is an overly restored, pretty to look at, set of ITB's, with little to no performance advantage. But, it was fun to do.