Hi guys,

As my build will be using an sr16ve head and the stock plenum faces the wrong way. Chopping and flipping the stock VE plenum doesn't look like a neat option as the runners wouldn't line un correctly. Also thought about chopping a stock s14 sr20det intake and welding it to the VE flange, but to be honest, the DET runnerrs are alot narrower. I was discussing this with a friend and he so happens to be a metalworker so he offered his services to build me a plenum that would mate to the lower VE runners (xcessive style). I would need to provide him with all the sizes and shit though...

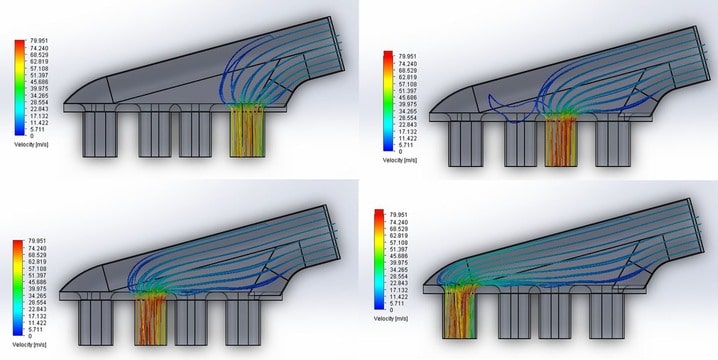

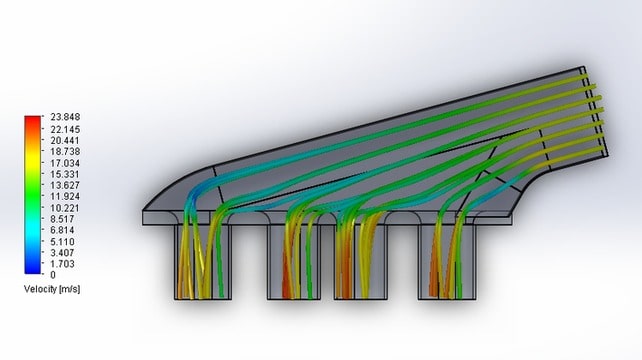

So i pulled my CAD knowledge out of the old closet, pulled some cracked cad software off the net and started right away and even did some flow simulations on the darn thing.

This is where my design comes to a halt... I have no knowledge of intakes so hopefully some experts are willing to enlighten me a bit on how i can make improvements instead of second guessing.

The numbers are in but same as above, i'm not sure how i can use these numbers to improve my intake design.

The simulation was done without the transient conditions of an engine. So the figures you see below are of static flows (?). I would like to do a transient flow simulation, but am unsure how...

Parameters used:

Medium: Air

Mass flow rate: 0.14 kg/s (equals to +/- 300cfm, what the head would flow)

Pressure: 1 bar

Plenum size internal volume: 3.7L (including runners)