|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Nissanaholic!

Join Date: Dec 2003

Location: In a place, near a river, over a lake

Age: 37

Posts: 2,415

Trader Rating: (22)

Feedback Score: 22 reviews

|

Snapped another throttle body - SR20DET - PICS

So here we go again, I broke another throttle body on my SR. The first time this happened, the #4 ate the screw, I lifted my head gasket and kicked a rocker in the head. After I switched to the "new" one I decided to weld the backs of the screws encase this happened again. Well luckily that move saved my motor and I just broke the axle again. Basically all components that are related are as follows.

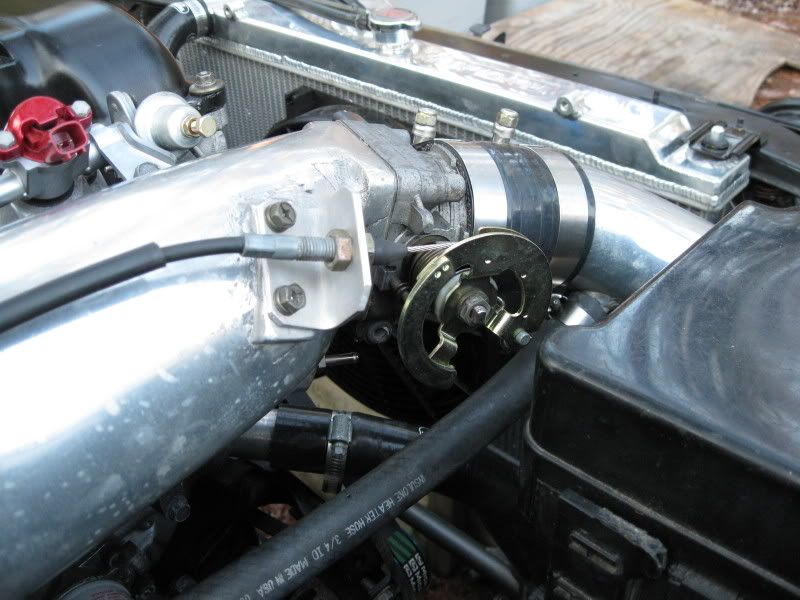

Freddy Intake Manifold OEM throttle body assembly S14 SR cable pulley 240SX throttle cable custom base bracket. Here is a picture of that:   Here is the carnage from the first episode. Now consider I'm not your typical "throw shit together" enthusiast. I like my car to work well and I plan for that in my build. I can't say it wasn't over pulling the stop the first time, b/c I honestly don't remember, but I will say I assure you that I set it up with good intention and adjusted everything appropriately; I thought.  Found this in the #4 cylinder with a magnetic wand    On the second throttle body I can assure you that there was ABSOLUTELY no chance I could have over pull the throttle body. I was very meticulous on the second install and was sure i had it adjusted well. Not to mention I also welded the screws to the center axle to be damn sure they couldn't dislodge. Like I said, that luckily saved the motor this time. The break was in the same place as last time and it doesn't look as though the welding had weakened the axle any. Here are a couple shots of that.    I'm not sure what I aim to gain from this thread. Maybe it will be useful in the future to someone or maybe someone on here has dealt with this before and can provide some incite. Currently I'm sourcing another OEM throttle body and plan to weld the screws as before and install as I had it. I'll then set up an indicator and see if I can't measure some amount of deflection. It wouldn't be difficult to weld on a "spine" or some additional material but I just wouldn't have thought it would be necessary. I'm also planning to review the base bracket and see if that isn't part of the culprit. Any thoughts? Experiences? For reference, the car is tracked as a drift car and makes just over 400 to the wheels.

__________________

Fu*king ginger bread man stole my wallet... SHIFTlock_slide to side d3m3rs0n: if i have a baby im naming it Brandons Fault Emerson |

|

|

|

| Sponsored Links |

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|