|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#31 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

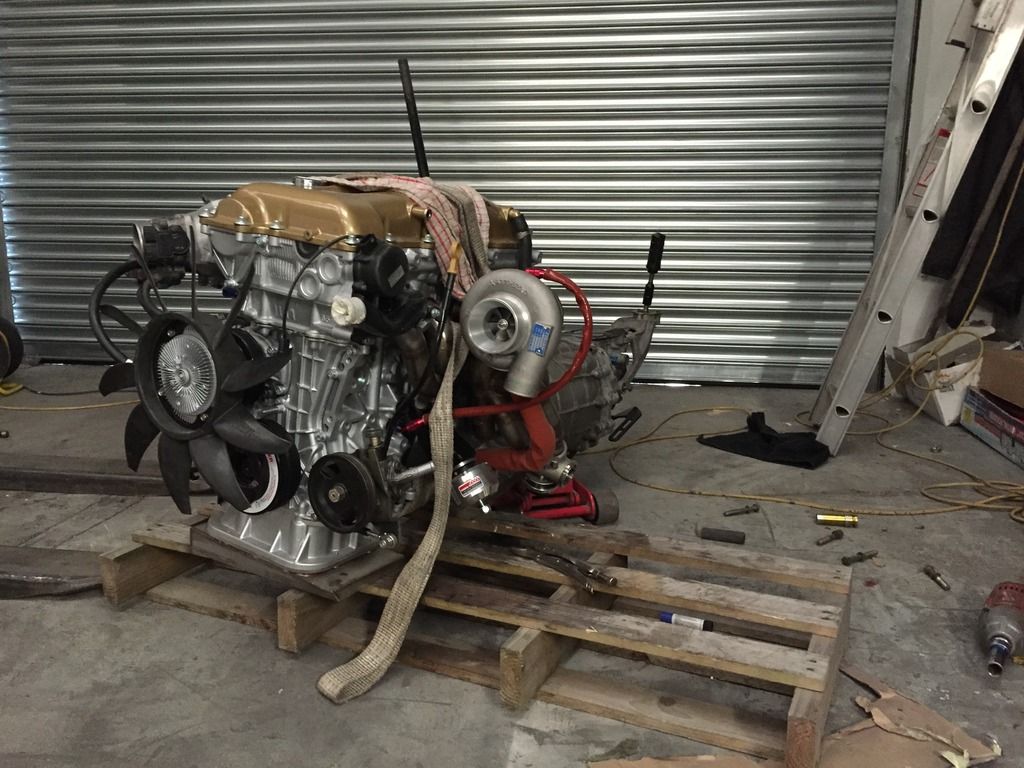

Had a pretty relaxed weekend on the car this weekend!

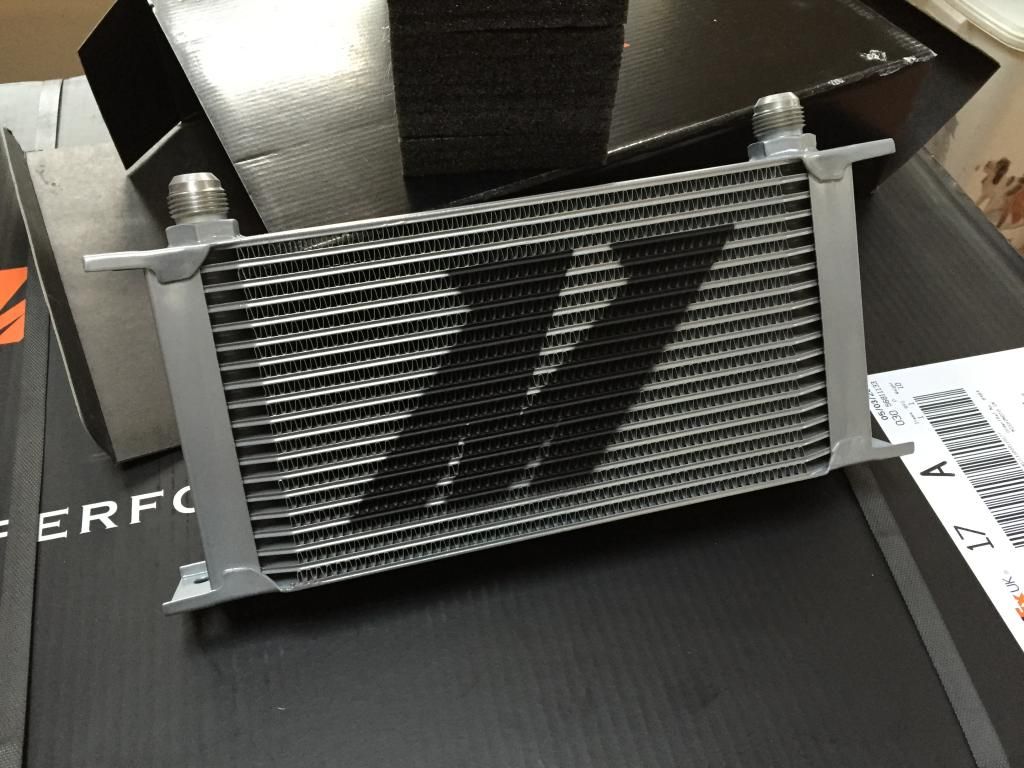

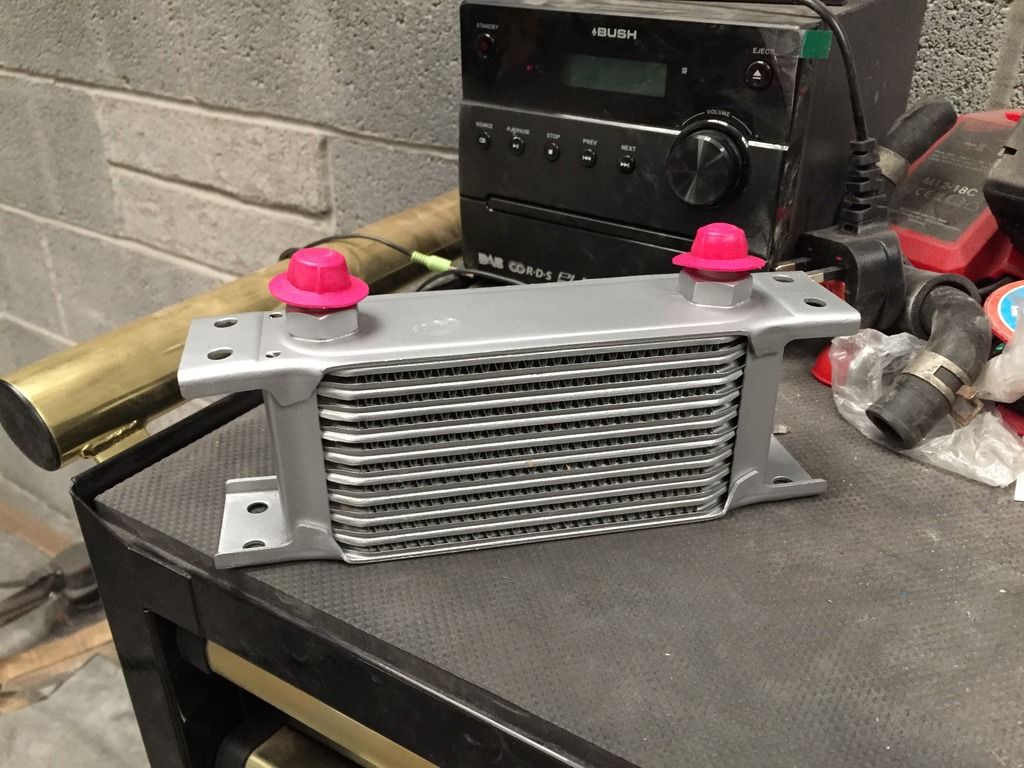

Mishimoto delivered the new 180sx 3-Row/X-Line radiator and 19-Row Oil Cooler pretty fast which I was amazed about. What amazed me more was the quality of the packaging and the goods that they produced.  Unfortunately my new intercooler core didn’t turn up at the same time, but as long as it arrives before Saturday when the car is scheduled to head off to Huxley again then all is good  Spoke to a few people about what size oil cooler to run, to which everyone said the 19-Row will be far to big for my needs. But I carried on, did some measurements and its perfect for what I want!  The quality is pretty decent, hands down one of the best cores I’ve held which gives me confidence with the setup it’ll be tasked to cool down. It came with AN10 fittings too, which just so happens to be the exact size of the Tomei Oil Block and Grex relocation plate  Even the radiator was really well packaged! Good to see some companies pride themselves in the packaging of a product.   Again, the quality of the radiator is second to none. This will be more than enough to keep the SR cool, my ebay/japspeed radiator managed thanks to the GKtech Fan & Shroud setup. So with 3-Row core im sure coolant problems will never bug me  (That’s the plan anyhow!) (That’s the plan anyhow!)Yesterday I was luckily enough to roll the car into the new unit! Weather was good, music was on, positives vibes everywhere which was a nice change. I handed my university dissertation in during the week, which was a massive relief, and now means I can spare some time here and there to work on the car   The whole no rear bumper look may be something I have to get used to, considering fibreglass and D-Max Type 3 usually end up in this fashion!  So much room for activities! (PS: The worlds best engine crane is in the picture!)    I still cant stop staring at the engine, so much work and thought has been put into it.  Japspeed special engine mounts are next on the list to go, options are currently Vibratechnics (££) or Apex Race mounts. I don’t have to decide for a while yet, so plenty of times to consider alternatives. Although, I do love the look of the C’s Garage & Garage Zeal mounts from New Zealand! |

|

|

|

| Sponsored Links |

|

|

#32 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

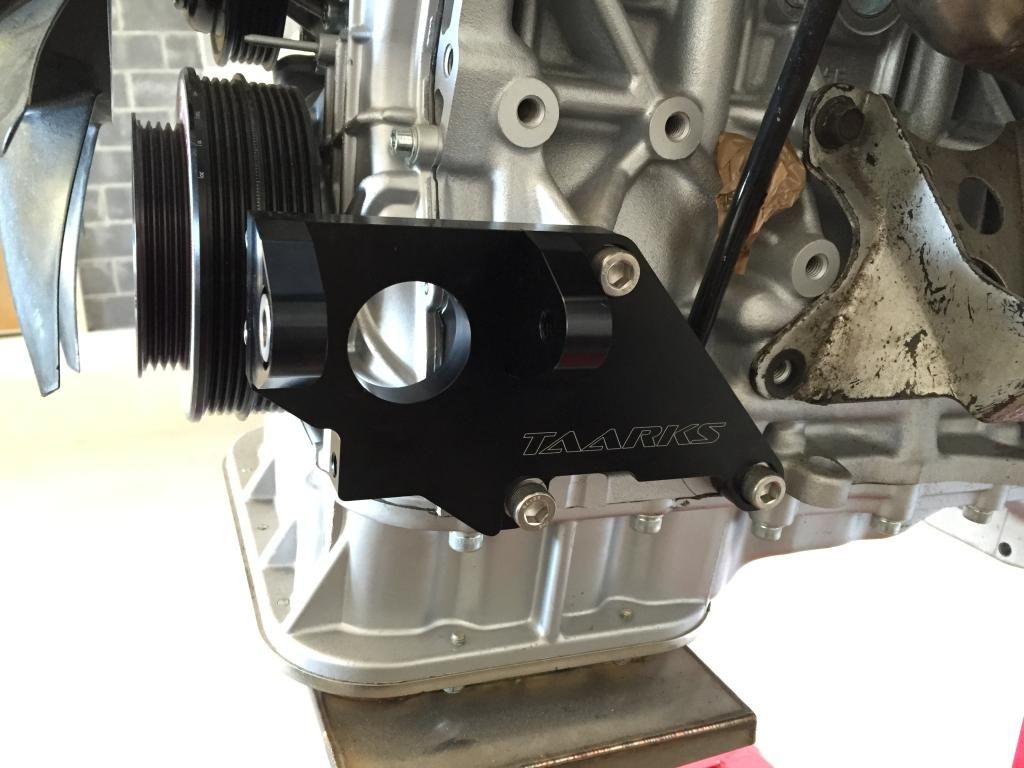

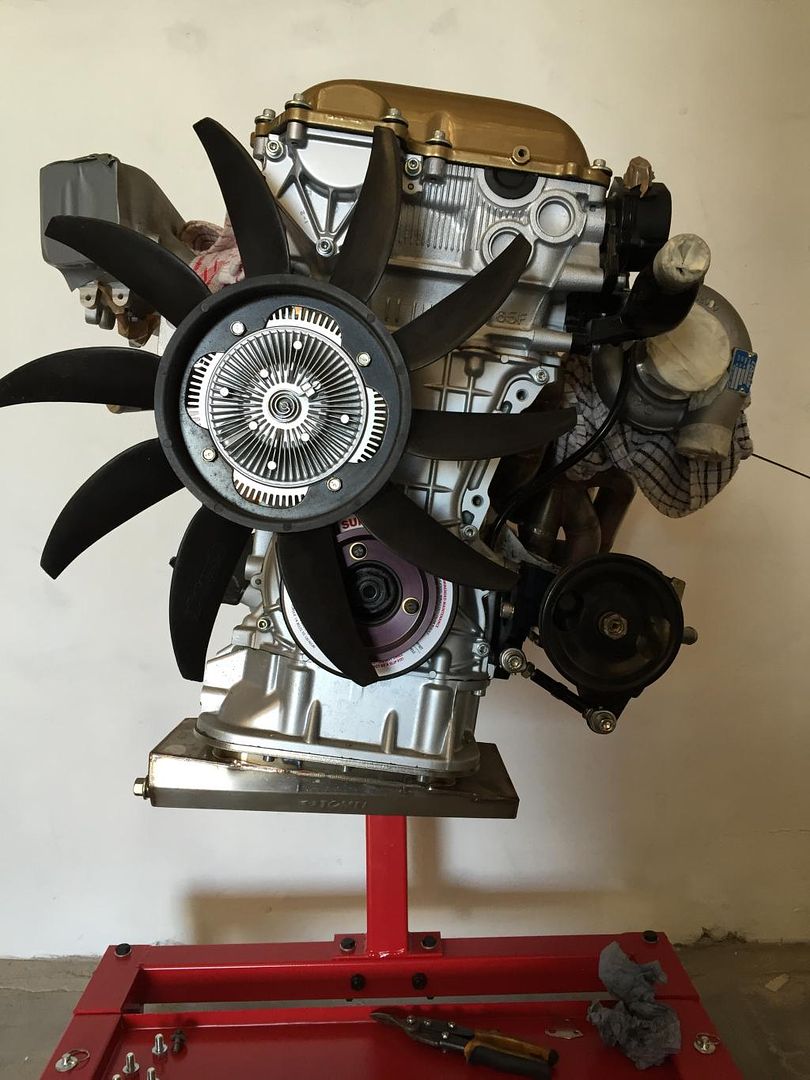

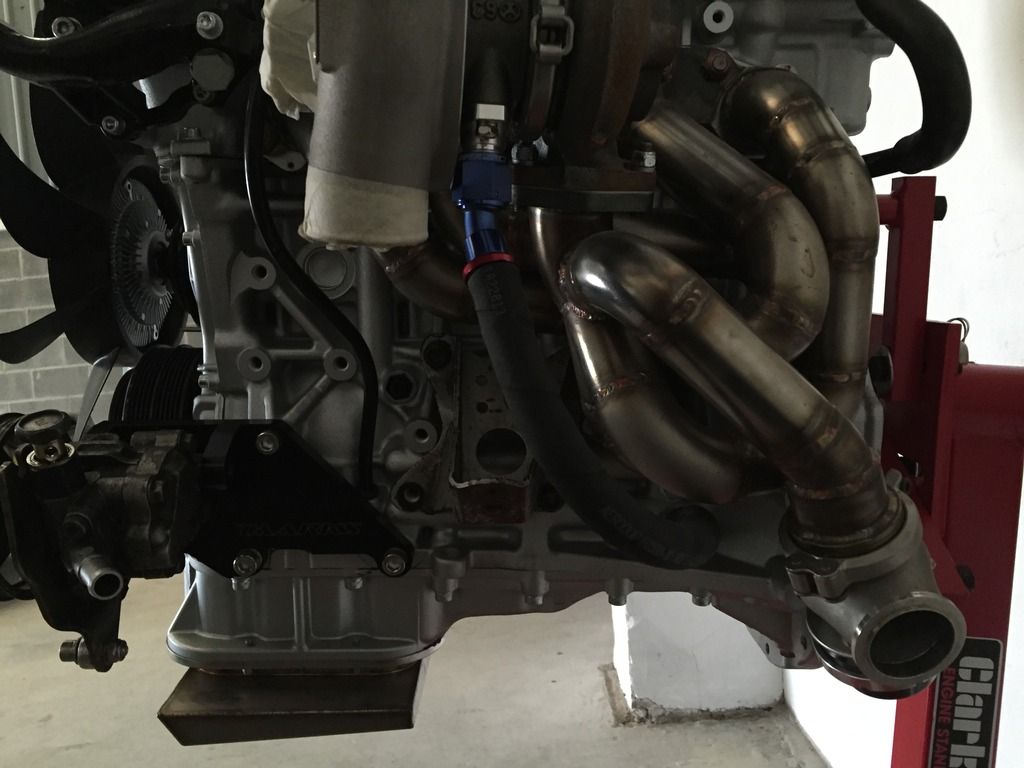

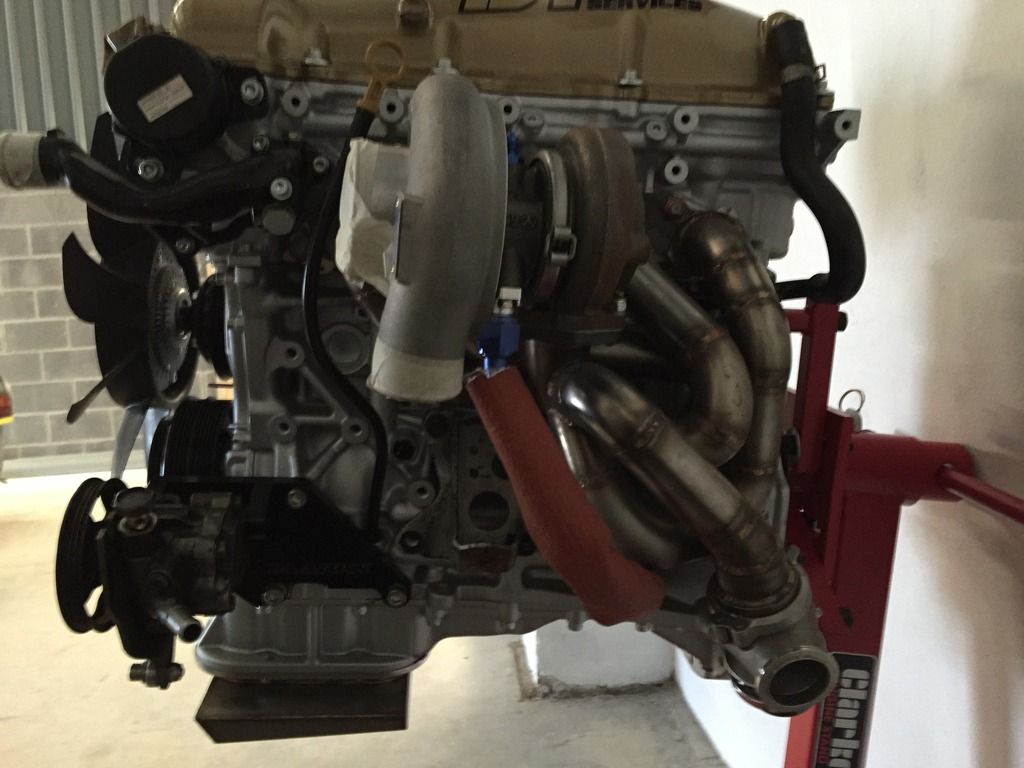

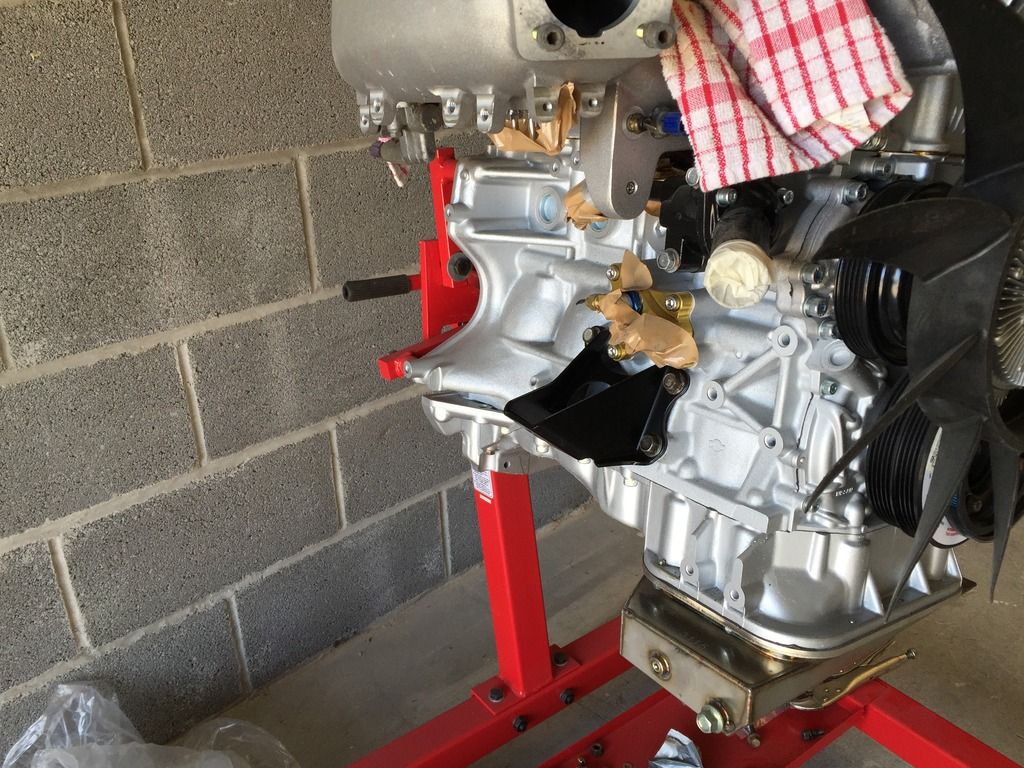

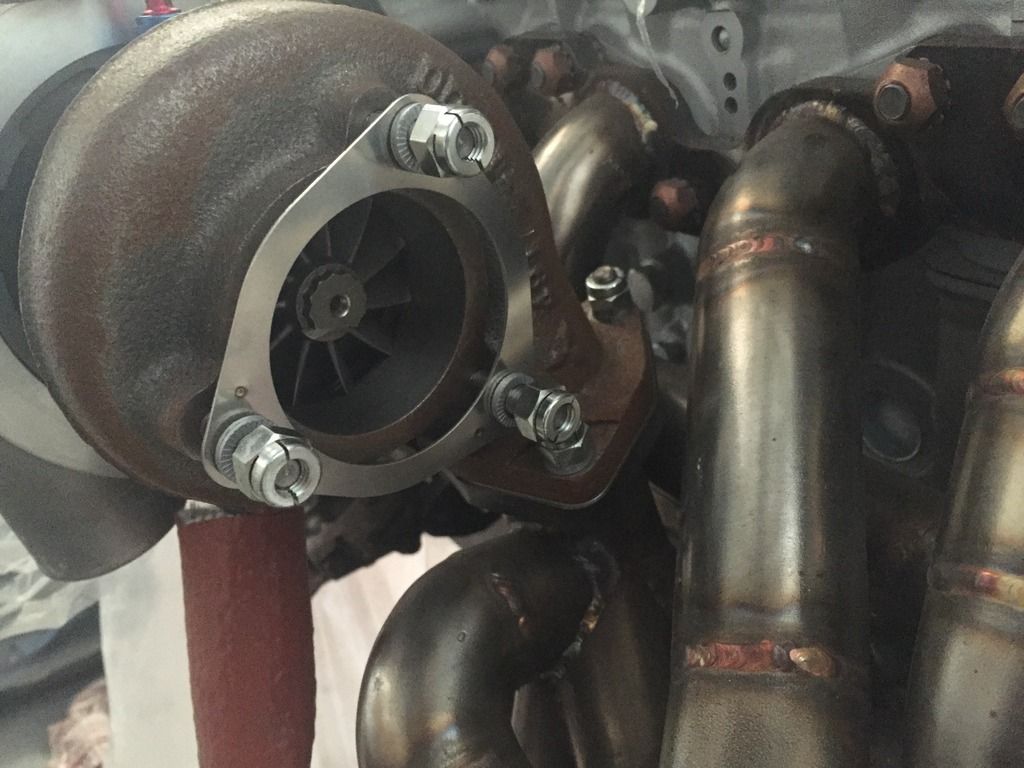

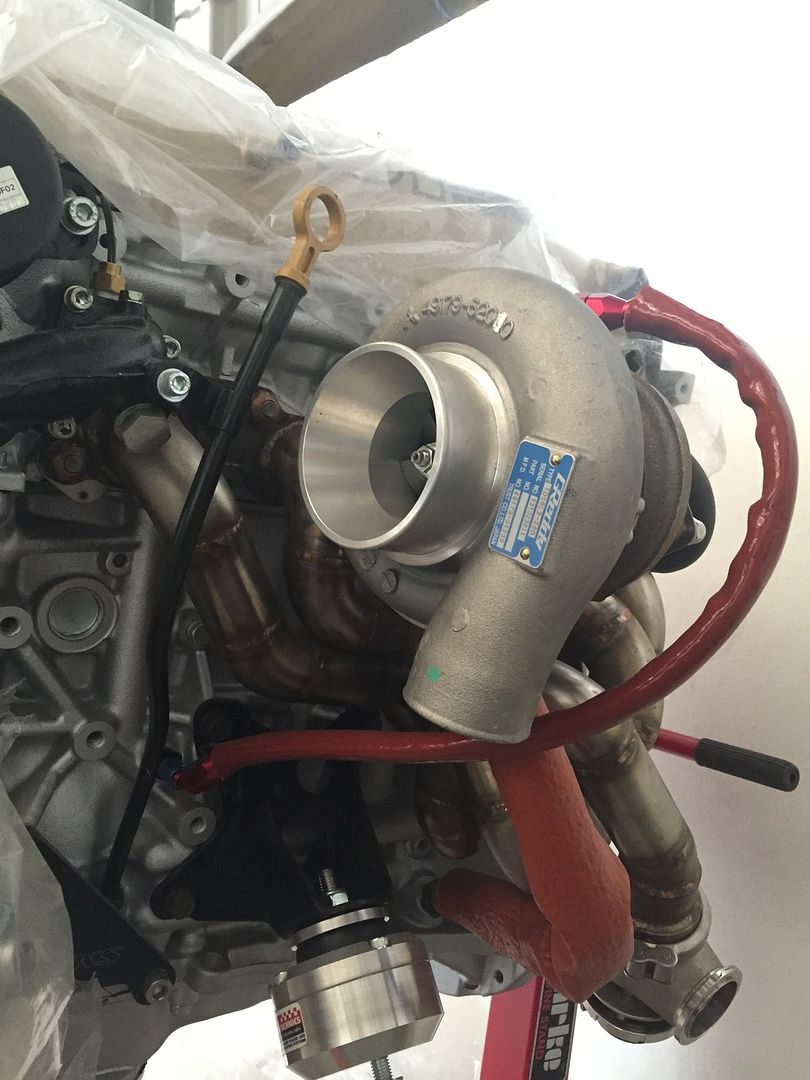

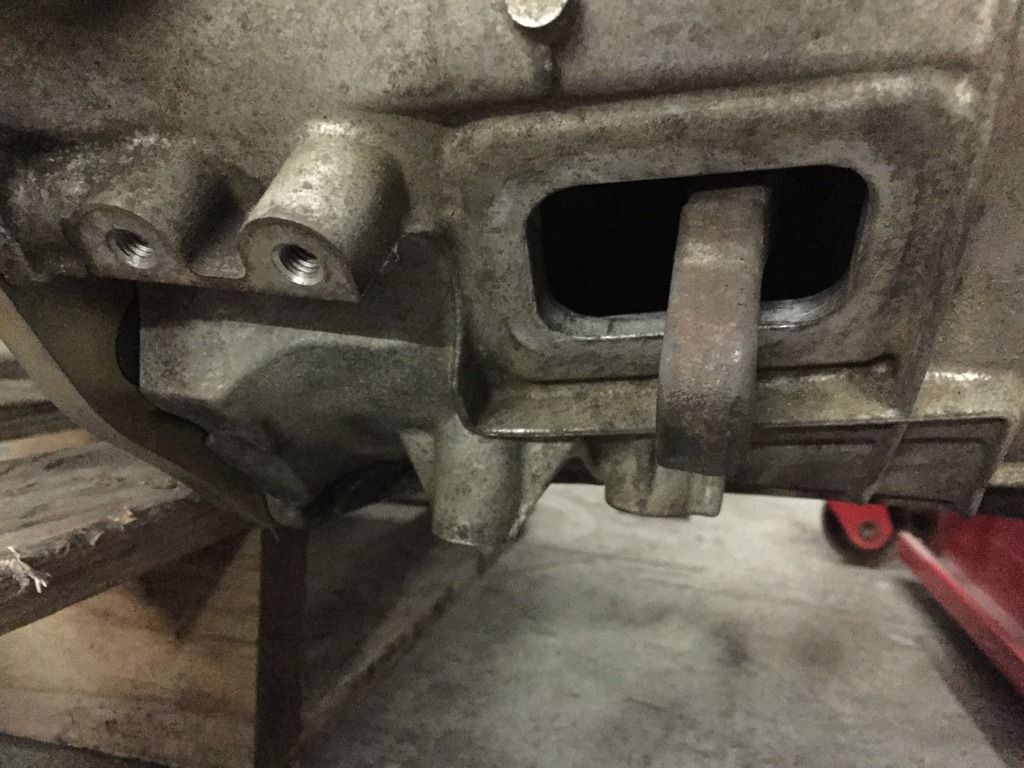

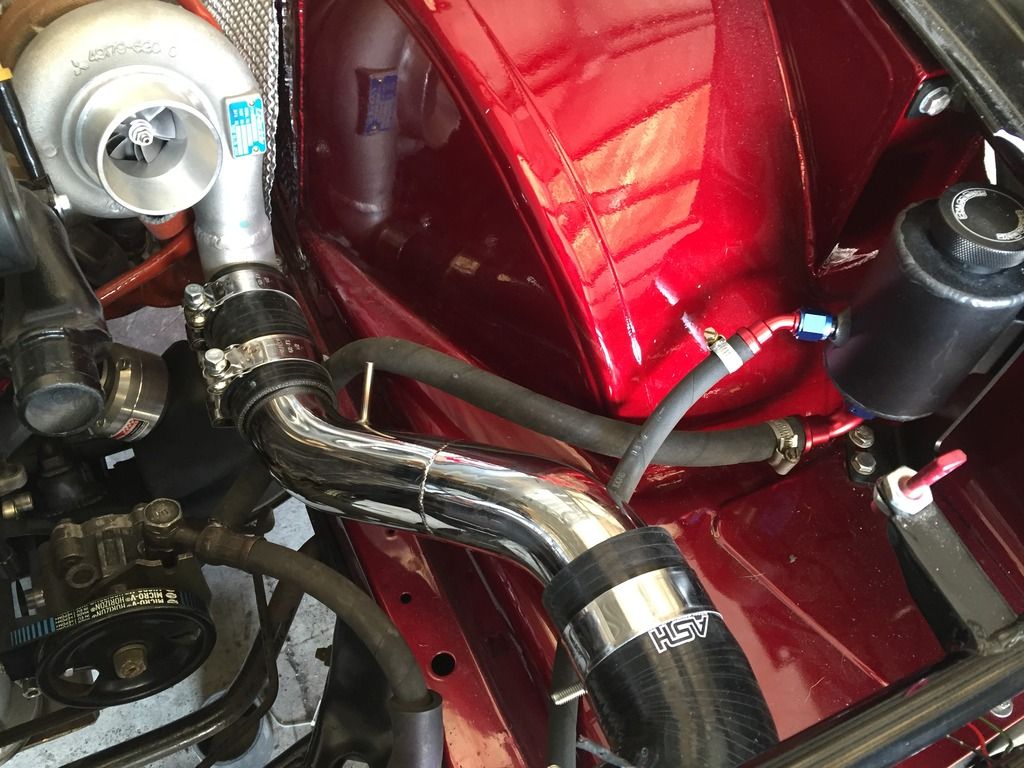

When the car returns to Huxley, the engine needs to be removed, plus I need to start building the ancillaries on and tidying everything up. This gave me a chance to finally see the artwork Huxley did on the downpipe.

Somebody told me that the TD06 needs an immediate 3” downpipe to make big power, although after speaking to a couple of people, they think the 2.5” ex. housing is plenty for the turbo, so with a couple of inches running at 2.5” and then to a true 3” downpipe, I’m sure this setup will be spot on for the power and boost I’m hoping to run through this setup. Even the screamer pipe that Huxley made is gorgeous! Points to the floor, and I love how the exit is ever so slightly curved. This should be making some very ear pleasing sounds!  So I whipped the engine out using the forklift with my dad and placed the engine on a stand. I bought a power steering pump relocation plate thanks to Taarks where the idea is to relocate the pump to where the A/C pump sits, moving it out of the way of the turbo, and well, I’m not one to hide my turbo behind the power steering! The kit had everything I needed, and the quality was flawless. Everything fitted, no modifications needed.    I also got round to clocking the compressor housing to roughly what it’ll end up as. Thankfully, the TD06 just uses a large circlip so should I need to alter the positioning, it can be easily done in situ if needs be   Started to offer the front end back up together, as I need everything to roughly fit or know it’ll fit so Huxley can do his magic and make everything whole again.    It seems the Origin wings may need a bit of work here and there, but only little thinks like the moulding around the passenger sidelight isn’t straight. But I’m hoping everything can line up roughly with Huxley and I can fine tune things once the car is back. I spent the day today removing the remaining rear glass today. This is so that when I come to spray the interior it’ll actually be doable, rather than trying to bend around the jungle gym that’s inside. The rear screen came out nicely, the remaining side window however made a break for freedom and decided to shatter into a million pieces! Fear not, my plan was always going to include the use of Lexan side & rear windows. The glass in the Silvia was quite simply s***! Whoever has owned this car previously obviously took no considering to maintaining the glass or covering it up when welding that lethal cage in, resulting in scratched, burned and just damn right terrible glass. So with fresh Lexan rear windows, everything will be looking fresh again! And this is how I left the car tonight. Seriously cant wait to wind those coilovers down the correct ride height after the next trip to Huxley.    Next on my list is a roll cab toolbox. Its time I finally sort my stuff into one place now I have somewhere to work on my car! |

|

|

|

|

|

#33 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

Once I had a few spare hours, I set about fitting the rear over fenders - beginning by trimming the lips off each fender.

After a few rivets here, and a few rivets there - it all was done;  Dialled out some camber, aiming for near 0* so just went by eye, threw the rear disc and 25mm spacer on to see how my old 18x9.5 +15's sat, and to be honest they sit near damn perfect!  Once lower, the arch should cover the tyre and if it the fitment is perfect, the fender should just cover the lip of the rim   Whilst doing this, a nice little package turned up today from Mishimoto, the intercooler core!    But the quality like the rest of the gear is fantastic! Cant thank them enough for getting the parts sent out asap. So thats my cooling elements chosen and bought, can't wait to see how they look on the car, although I'm not looking forward to buying x4 AN10 lines for the oil cooler setup. It's nice to have some positive vibes on the car, meaning I can slowly envision the final product, and I seriously can't wait to back on track! Nothing special, but a few pictures showing how the car is standing at the moment;     Ordered a couple of bits up today, mainly parts for the oil feed and drain for the TD06 with help from a friend, so can't wait to get all that done. Im hoping this week at some point to go and grab a roll cab/tool chest to try and organise myself and begin gathering quality tools rather than making do with what I've got, something I'm kind of excited about in a weird and wonderful way. |

|

|

|

|

|

#34 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

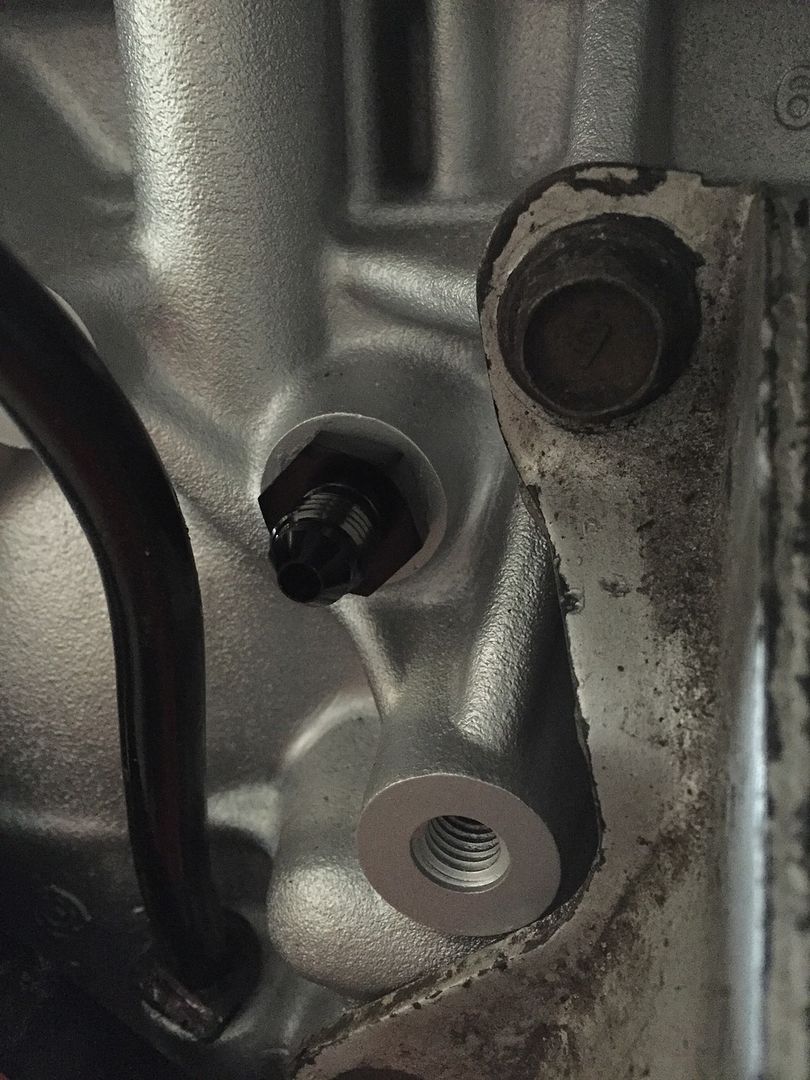

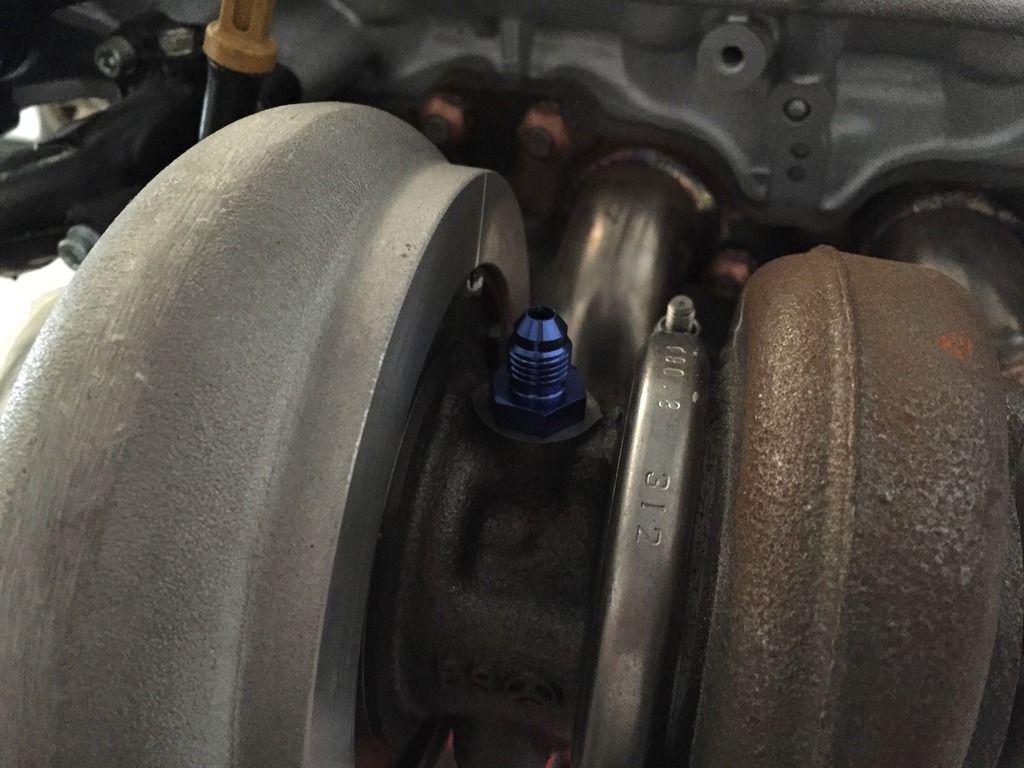

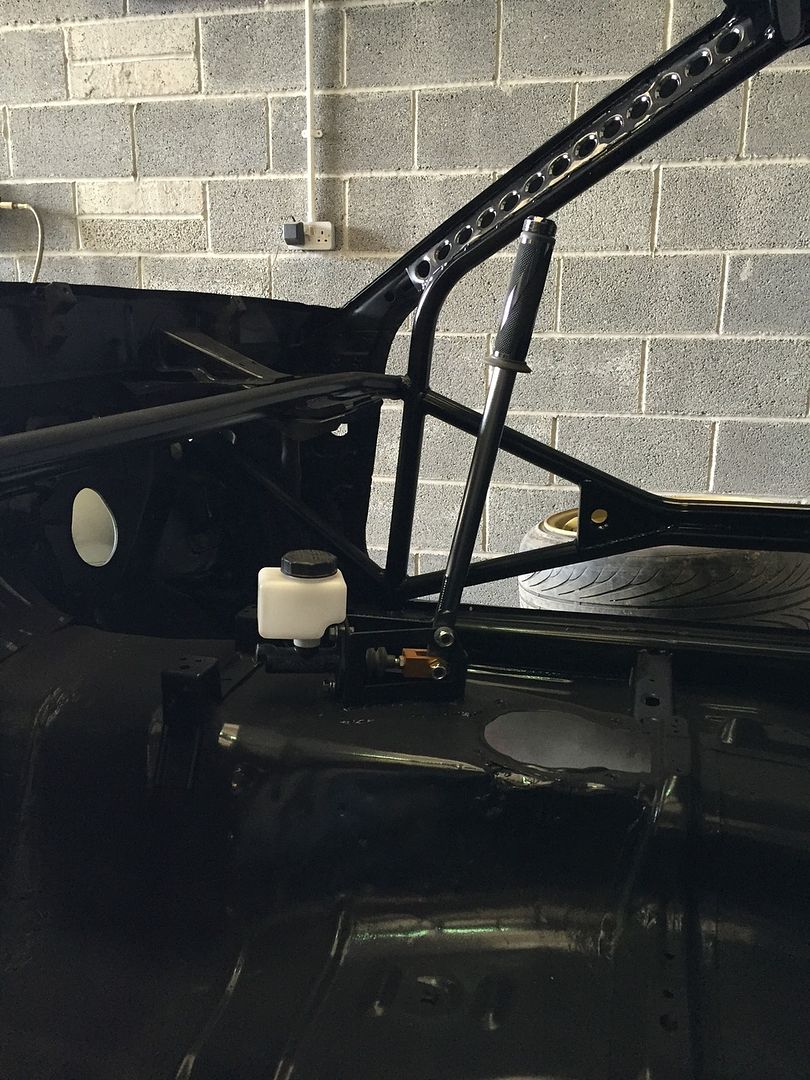

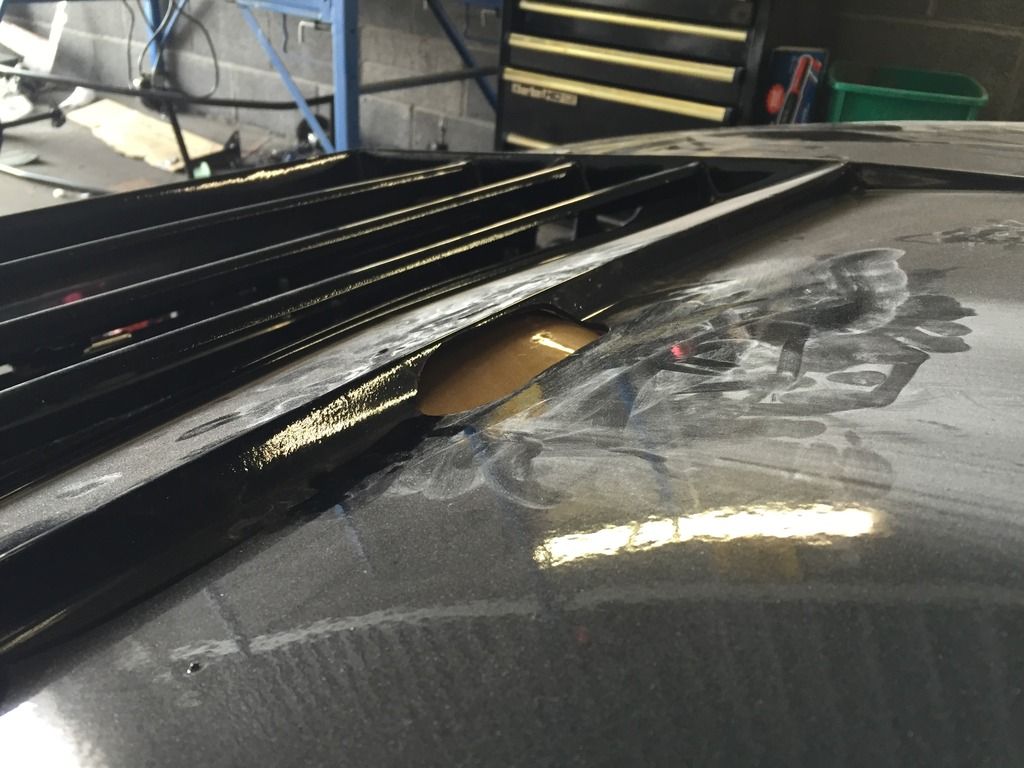

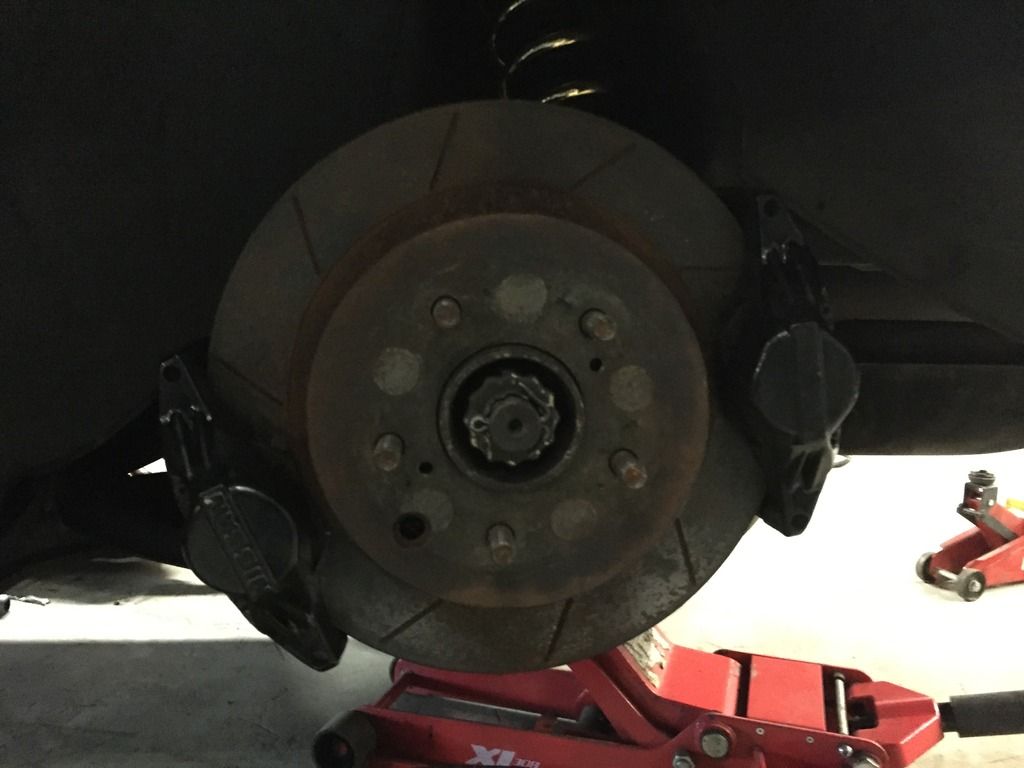

y fittings turned up this morning from Torques so began by offering them up to see what the score was. First up was the M12x1.25 > AN4 for the block side;

Then the M10x1.25 for the TD06;  Next up was the AN10 Push Fit/Socketless fitting for the drain. The drain was always going to be tight due to the design of the runners, but after speaking a friend with his setup, I followed in his footpath, and its tight, but it clears the bottom runner without any kinks in the line    Threw some protective sleeving on that I had left over from a while back, and thankfully it was the correct length. Only offered everything up and I still need to grab some quality hose clips before finalising anything. Pretty chuffed with the result too!   Over the weekend I spent some time doing a job that I didnt want to do  I had to cut up the shiny new D-Max bonnet.. I had to cut up the shiny new D-Max bonnet..I took my time with this, measuring the templates to make sure they are exactly where I want them, plus I want them exactly equal seeing as I only have one shot at this.   After a couple of hours they were done! Without making a mess of the bonnet too  Hopefully this makes Huxley's job easier when he places the pins type parts. Hopefully this makes Huxley's job easier when he places the pins type parts. Began fettling with the front wings again, and remembered how much I hate fibreglass mouldings. Managed to make my corner lights sit nicer, but there are quite a few moulding imperfections so they'll require some loving to make them all equal once they are back.  Quickly threw my seat back in to double check the hydro position and its perfect :smokin: Couldn't resit a quick snap of the seat though...  Next up - Back to Huxley Motorsport! Not long after the last update, and friend had the lovely job of trailering the car back up to Huxley. By the end of the first day, this was the kind of progress Hux had made.    Pretty impressive if you ask me  Then came the task of the tubular front end, which I think Hux has nailed;    And then, it finally resembled a car for once! I can't described how stoked I was when he sent me this picture. After all the time of looking a car that doesn't even look like a car   We did encounter a problem though, where the intercooler I had ordered is 4" thick, instead of the regular 3" cores people tend to use. The problem here was that for the core to sit where Huxley usually places them, it would clash with the headlights. So we had 2 options; a) Move the rad back b) Fit the core more forwards and in front of the front crossmember So after looking at some pictures, some discussion we opted for (a) and moved the rad back as little as we could. After looking at my pictures, theres tonnes of spaces between the viscous and the rad, just the cowling may need to be "modified" which shouldn't be a big deal, hopefully! Thanks to my friend we went and grabbed the car off Huxley last night, and to say I'm thrilled with the work he's put into this car is a massive understatement. I can't thank him enough for turning a shell with a dodgy cage and front tubs, into a car that has a full blown jungle gym of a cage and a real fancy front end! :smokin:  The crash bar is awesome too, the bumper hugs it so tightly its unreal, in a good way! Bumper does not sag, and its much stronger than the original "crash bar" than Nissan think is sufficient. Few pictures once I got the car back into the unit last night;   And was greeted to this today! Shouldve been revising today, but the car took priority. Need a break from so many textbooks anyway   FINALLY! The front end was lowered, although this was the maximum the coilovers would allow. After all, they are optimised for performance, and they havent been bedded in yet (although they are hard spring rates!)  Then I began to lower the rear, again, this is maxed out but to be honest, its exactly the height I wanted so I'm not phased. I could go lower through adding droop but I think this will do, and ill let the fancy springs do what they have to do and give me better grip    May have noticed the front brakes;  They are huge! Cant wait to see how they feel out on track though  I also threw on the rear Z32's to see how the dual caliper looks. Unfortunately I didnt grab any pictures, but it looks pretty cool and again, I can't wait to try them out and see how good the hydro is. I also threw on the rear Z32's to see how the dual caliper looks. Unfortunately I didnt grab any pictures, but it looks pretty cool and again, I can't wait to try them out and see how good the hydro is. |

|

|

|

|

|

#35 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

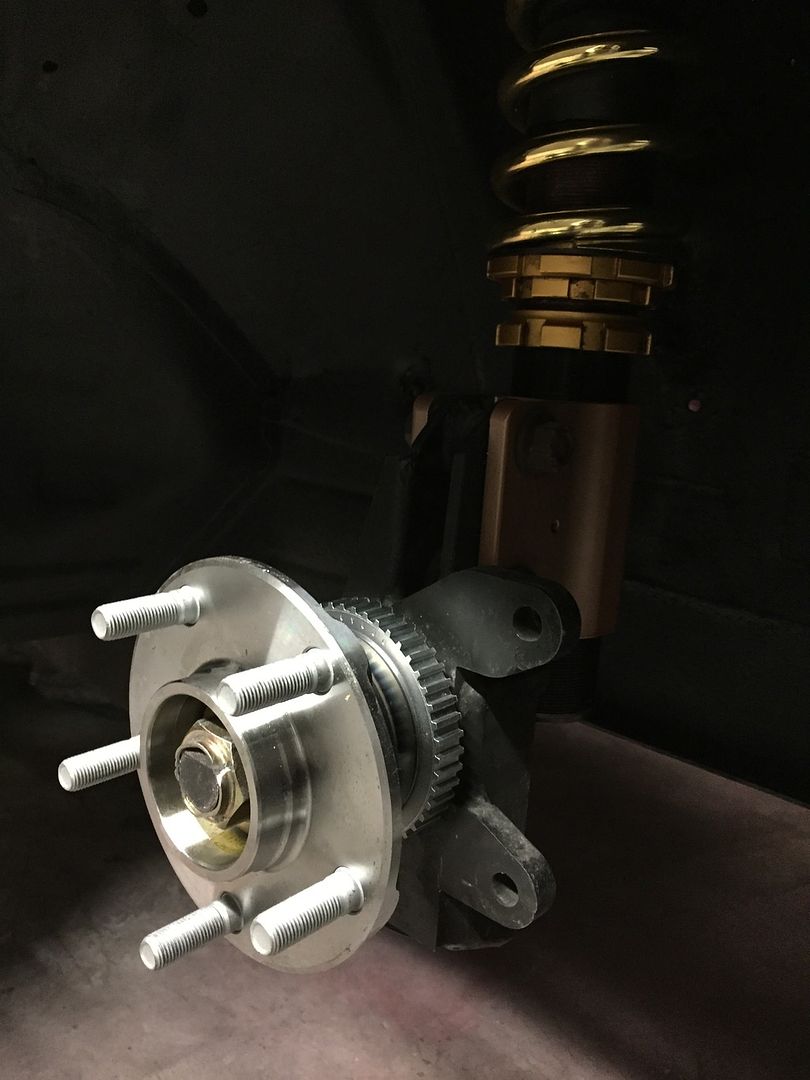

m planning on selling the Superclarkey hubs in favour of some front geomasters after hearing how they respond with huge flicks and angle :smokin: Plus, I could kinda do with the drop and the freshness of some new hubs and bearings

Whilst the car was away, I started thinking about the interior. I grabbed my old dashboard out of the S13 along with the centre console. I'll set about making a much neater dash and make the centre console fit along side. Even though this will be quite an extreme car, I can't help but have that little bit of "luxury" (If i can even call it that?) and make the car feel a bit more back to its roots. Threw the centre console to see how it'd fit around the hydro;  The next task was to begin fitting my old dash, with the hope of a much neater install. I wont bore you too much as it isn't the most fascinating of tasks but I've managed to try and retain the sides, and began to trim the centre console so that I can get the required throw on the hydro.    At this point, I started to kind of procrastinate which is not good! |

|

|

|

|

|

#36 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

o spent a little bit of time on the car today, so started off by getting the rear bumper to fit. When I mocked this up ages ago, the left hand side was a mile out! So after speaking to a friend the solution was to grab a heat gun, apply a bit of pressure and slowly put it into shape. And after about 10 minutes it was all but done, so I've left it in situ for the fibreglass to cool down and hopefully retain some sot of shape that its supposed to be

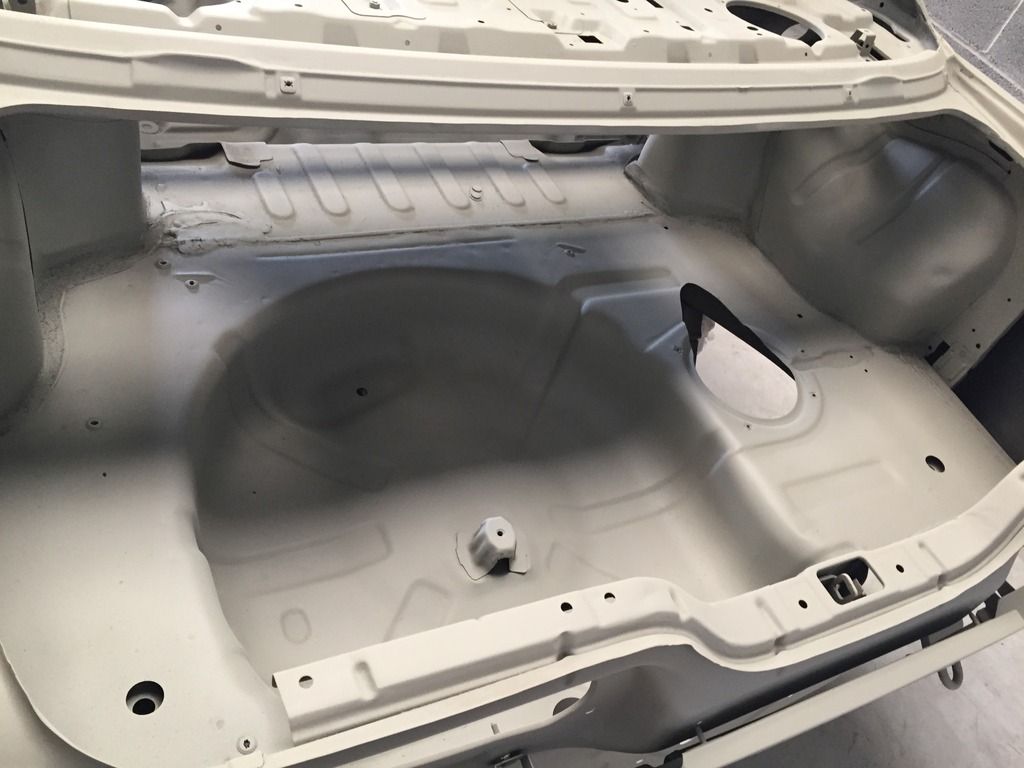

Rear ride height is spot on, can't wait to drop the front another 1/2" or so! You can catch a glimpse of the dual caliper setup, I should probably begin thinking about rebuilding them, that way the whole brake system is fresh     And then, I got a little bit bored so decided to put one of the 18x9.5 +15 Battles up front, along with a 25mm spacer to see how it sits;     Kind of loving this look. Ive spent so many hours considering new wheels choices but can help thinking my old wheels will pull off the look I'm thinking of, typical! I think another 5mm upfront and removing a shade of camber may help dial the front fitment out a tad. Cant help but think the style of front fenders cry for a wheel to be "under flush"/not poking? Either way, i'll drop the ride height and a lil more spacing and see how it looks  Me and my dad took his car down to the unit, and whilst we were there it'd be rude not to grab a quick photo! The difference in generations and the car that originally got me hooked into the mechanical side of things  Now I just have to convince him to ditch that Rover (Buick) V8 in favour of something with a bit more grunt :wack: Now I just have to convince him to ditch that Rover (Buick) V8 in favour of something with a bit more grunt :wack: I then spent the following weekend making the car look like total crap! But its all in the name of the greater good  It wasn't long until it was up and off the ground, with the whole front subframe/LCA's/Coilovers etc off. The plan here is so that I can clean the subframe again as its gotten filthy, as well refreshing the LCA's with some fresh balljoints and bushes ready for when I get a pair of Geo's to go on :thumbs:    Interior it totally empty now  I made a small cardboard template of a rear firewall kinda thing. Seeing as i'll be running a swirl pot, I think it'll be better to play it safe and have something between me and that should something come loose in the event of an accident. I made a small cardboard template of a rear firewall kinda thing. Seeing as i'll be running a swirl pot, I think it'll be better to play it safe and have something between me and that should something come loose in the event of an accident.  Here's a clearer picture of how the dual caliper will sit using the PBM rear knuckles   Removed a few bits and pieces from the rear end whilst I was there;   Looks like I've made a massive step backward, but now I can start prepping the car for paint and final fittings! Exterior colour is set, just a case of finding the rights shade for the engine bay and interior  |

|

|

|

|

|

#37 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

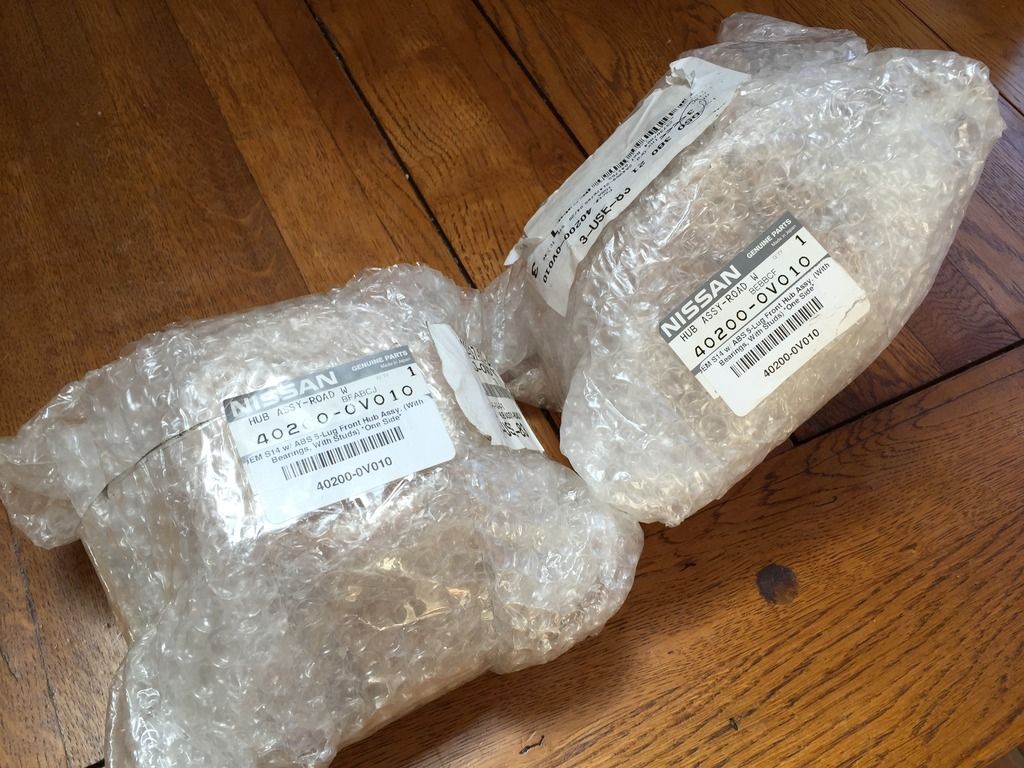

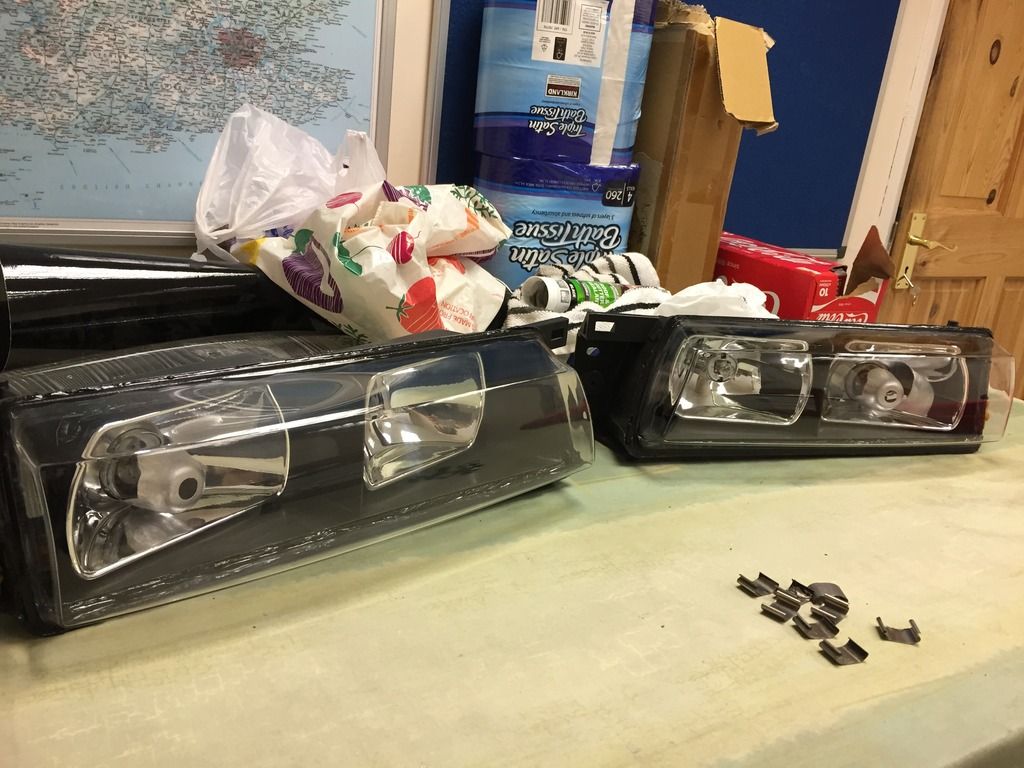

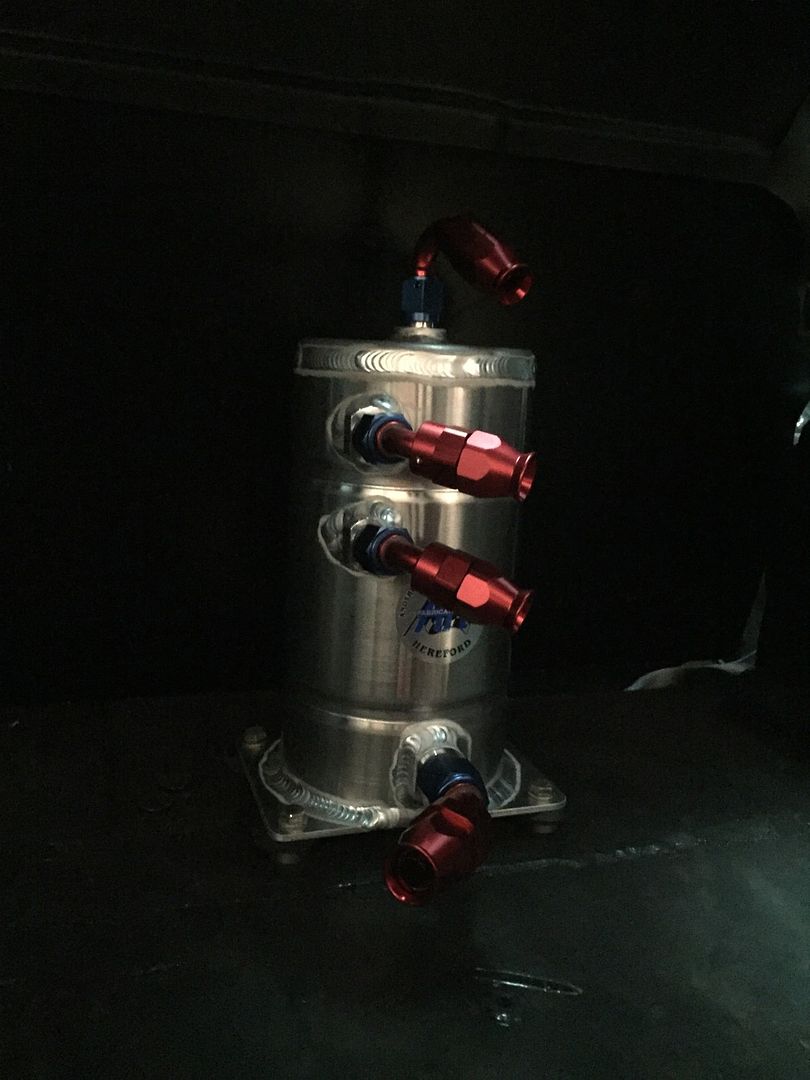

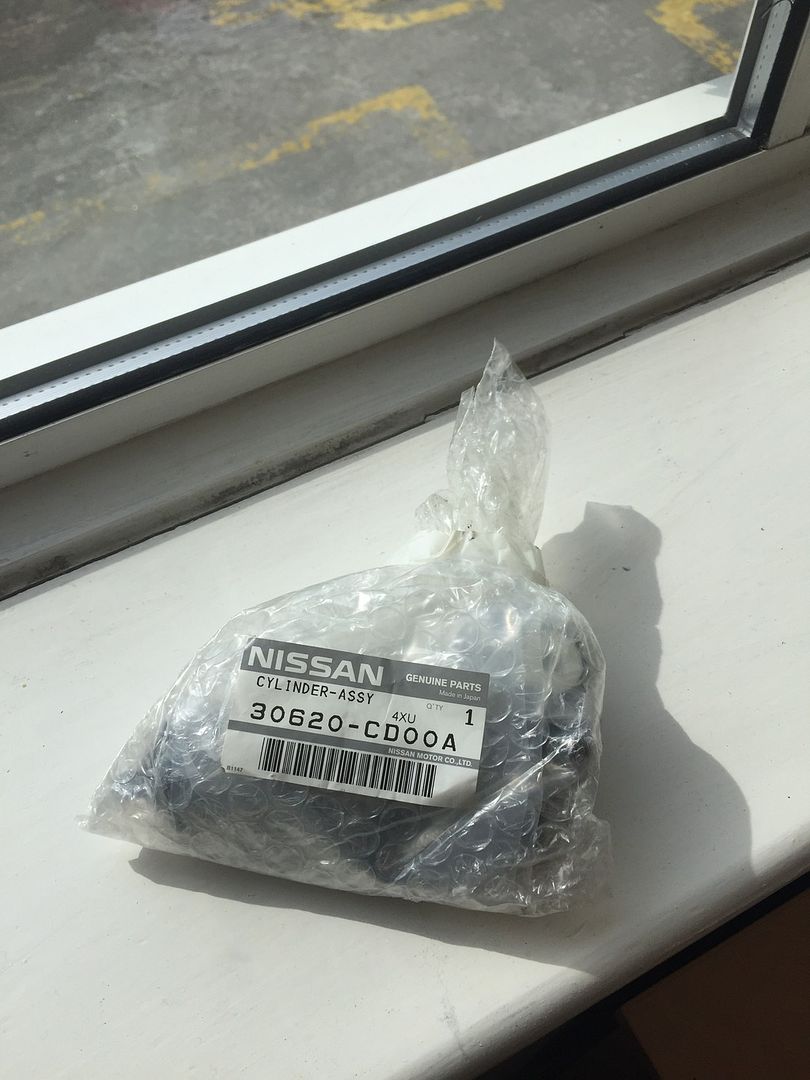

I’m all done with university now so that means I can get a few solid weeks on the car and try and make some progress here and there, and who knows maybe it’ll finally be in one colour!

First things first was to seal those gorgeous tubs Huxley did for me, where I will try and re-underseal the front at some point to give them an extra bit of protection against all the grime that they’ll inevitably pick up on track. I went to remove the front bumper bar and all went smoothly until the happened   Bit of an odd occurrence as Hux used fresh hardware but nevermind, these things happen and I’ve always needed a Tap and Die set. I tried some heat and some pressure to loosen it off but it was having none of it, so outcame the grinder and removed the exposed threads, drilled a 6.8mm(?) hole and ran a tap through and all seems well. Probably not the strongest of threads but it only needs to hold the bash bar in place and support the bumper.  One thing that become apparent was the really fancy PBM Pro coilovers didn’t go low enough on the front for me. As far as im aware, this is because the Pro’s have a longer shock amongst other features. Ive always wanted to run a “fresher” setup up front as I never took the time to get the cut knuckles powder coated so always looked a tad messy. I almost bought a pair of Geomaster’s new, until a set popped up for sale on here, and luckily the guy was passing near me so it was a no brainer! Whilst everything is apart, I wouldn’t mind changing the front balljoints for piece of mind and I have a pair of brand new OEM wheels bearings to go on   With the style I’m aiming for, the standard rear lights were never going to cut it. Thankfully Mitch put these up for sale, which were as good as new. The plan is to tint these all red, but I’ll save that job until the car is painted so I can double check exactly how each style will look. Worst care is the tint can always be removed  The SR/Z33 conversion is a bit of a mystery setup for those running fancy clutches like myself. My Twin Plate requires a special release bearing under a regular SR20 box setup, so this was the mystery to my as the standard procedure is to use the Z33 fork and pivot setup along with an SR20 sleeve and release bearing.    After scouring the OS Giken manual’s a number of times and searching the internet I decided to give the guys R B Motorsport an email as they are the UK OS Giken dealers. Luckily he had a 16mm release bearing and sleeve combo in stock, which is what OS Giken recommend for my clutch, so fingers crossed this works first time. For those with a keen eye, you’ll notice the bearing has a slightly different design to a regular release bearing, which supposedly should make the twin plate have a slightly easier pedal feel.  Cant walk away without having another look, the car has so much potential its unreal.  After weeks of studying everyday, I needed something to motivate me a bit more so had to make a lil’ purchase, and what better way than a pair of Work Equips?! These popped up on here, and were advertised as 18x10.5 -5, although I have a suspicion they may have an offset of around 0 after a quick measurement but I’ll double check that in the future. The guy I bought these off had an immaculate PS13 too, which was a spitting image of how I would run the car styling wise if I had chosen BN Sports originally.  I ordered these a while back from Jesse Streeter, but Defi had stock issues surrounding the boost guage. Its not as if I’m time constrained, but the wait was worth it. The boost guage reads up to 3bar rather than my preferred choice of 2bar, but it’ll work just as good. It’ll just look like I’m not running an manly boost   I’ve been planning to run a swirl pot setup for the fuelling side of the build, but there are so many options and with something as important as the fuelling, I wanted to shy away from the generic eBay swirl pots and have something that’s quite sturdy. I’m planning on making some sort of firewall, should something come loose, at least there is some element of protection between me and the swirl pot.   Over the past few days I have been concentrated on the bodywork, as I’m desperate to get the car in its colours so the final build can commence. I’m itching to drive so badly, and I want to hear my godly SR  Jesse Streeter once again came to the rescue and sourced me a pair of D-Max rear wings. I loved the rear wing on my old S13, so had to carry on that aspect of styling onto the new build.    Plastics4Performance sorted out plastic rear windows for me, where the quarter & rear windows will now be Lexan. The original glass is in dire condition in regards to small marks, poorly tinted etc and one important aspect of styling is decent looking glass! The front windows however will remain as glass. I did think about replacing the door windows but cant stand looking at windows that deform under high speeds, plus I wouldn’t mind retaining electric windows.    And that’s how the car was looking when I left it yesterday. Still needs a fair few more hours on body and interior prep, but I should probably start thinking about the engine bay/interior colour as the exterior colour will be easy to source. What impressed me was how the front bumper sat just resting on the bumper bar, a true testament to Hux’s workmanship. I’ll try and grab a photo of how the bar sits inside the bumper. Atleast I wont suffer from that horrible bumper sag. |

|

|

|

|

|

#38 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

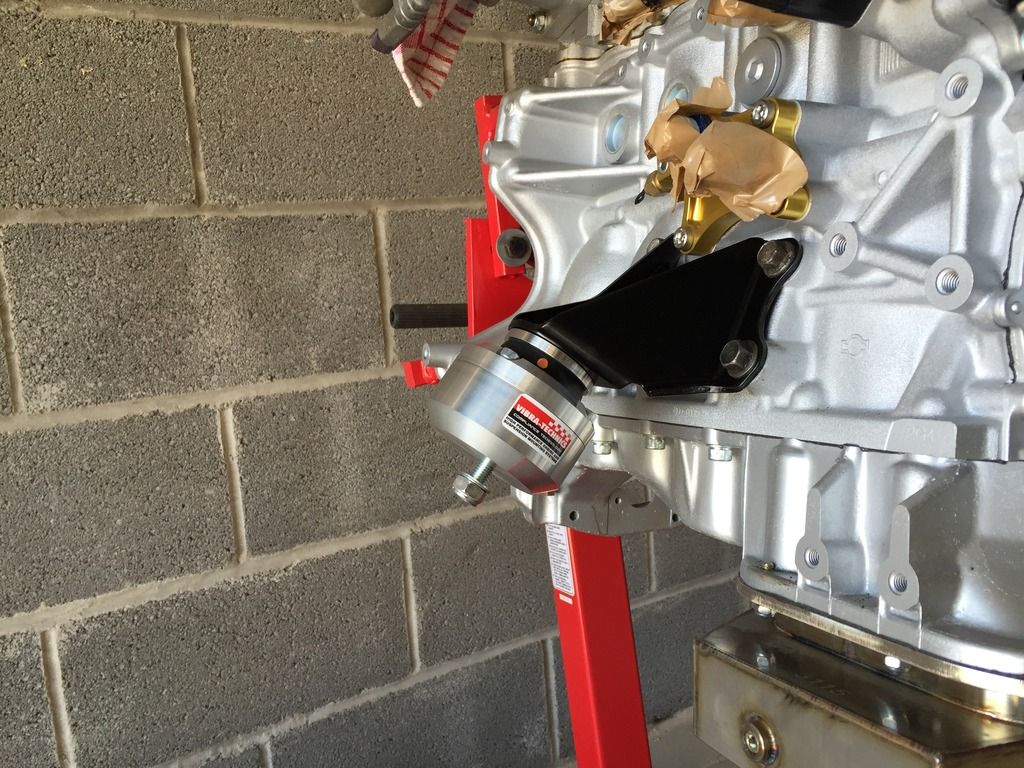

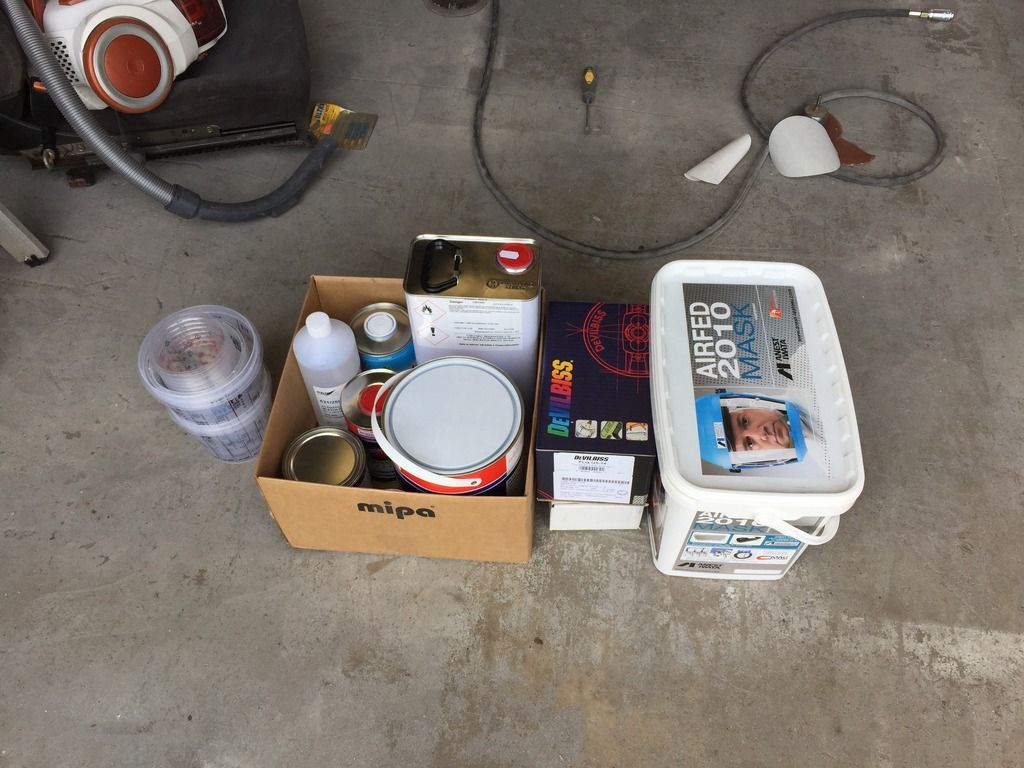

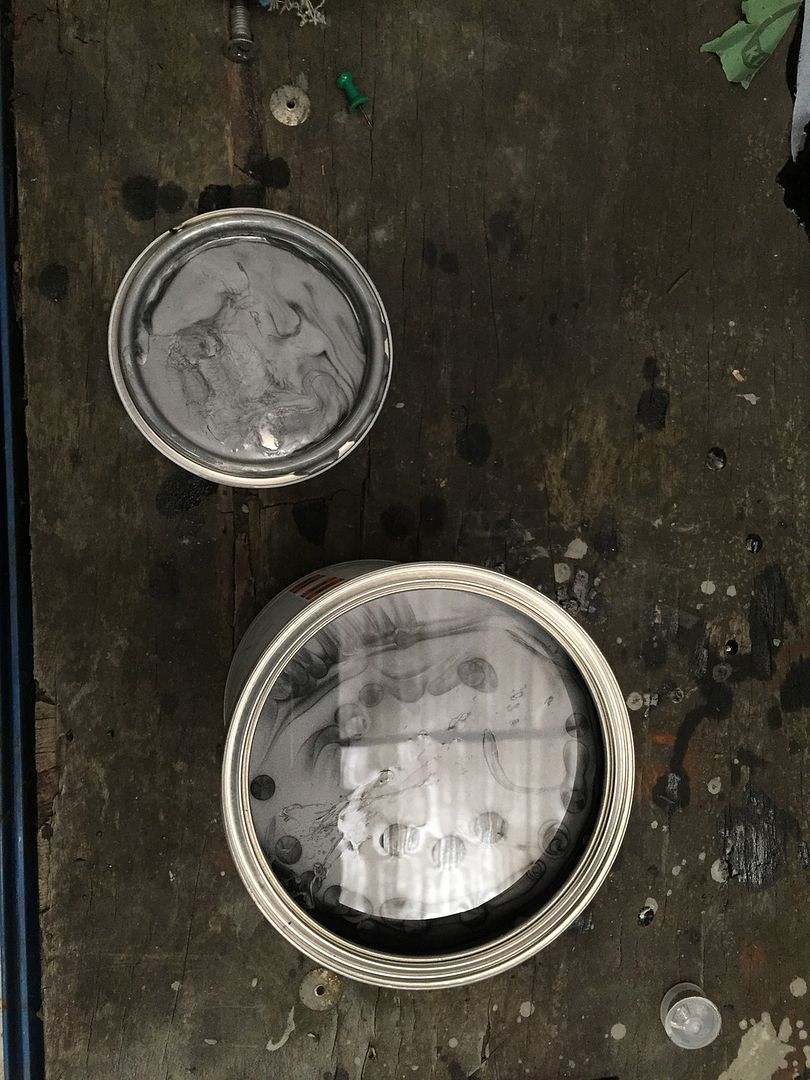

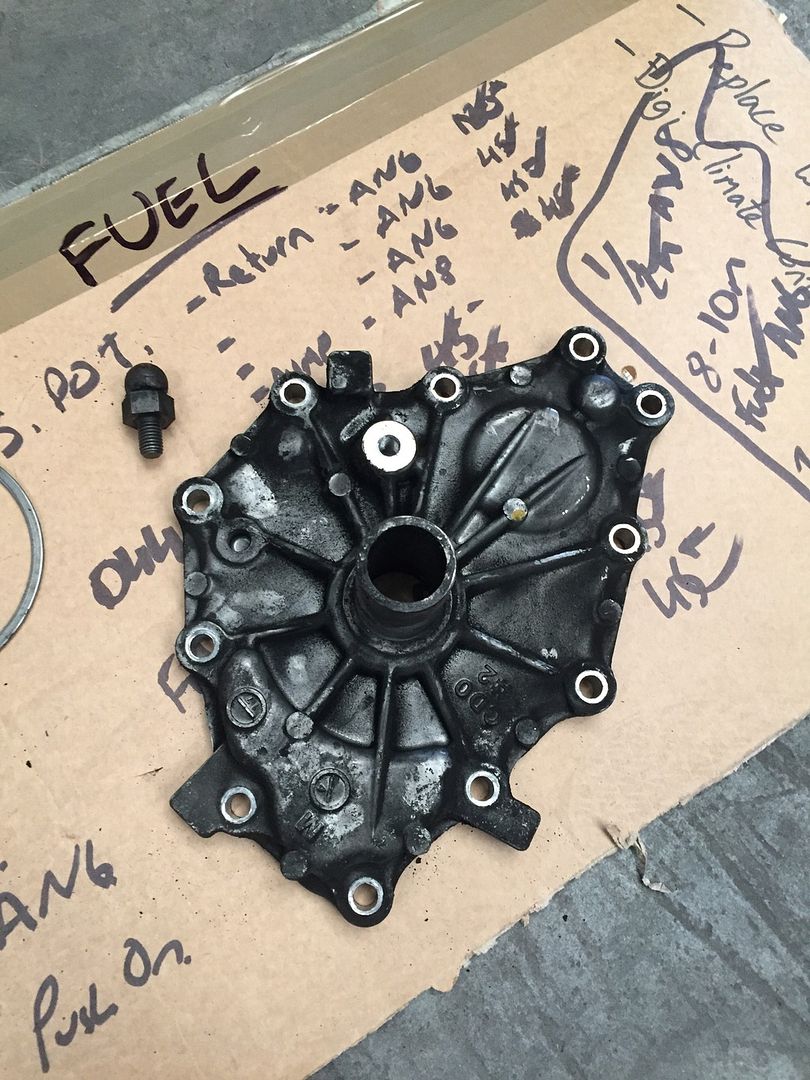

Not alot of progress has happened as it is just constant prep work. Vincent from T Works Automotive knocked up a cool little illustration of how the car looked all mis-matched:

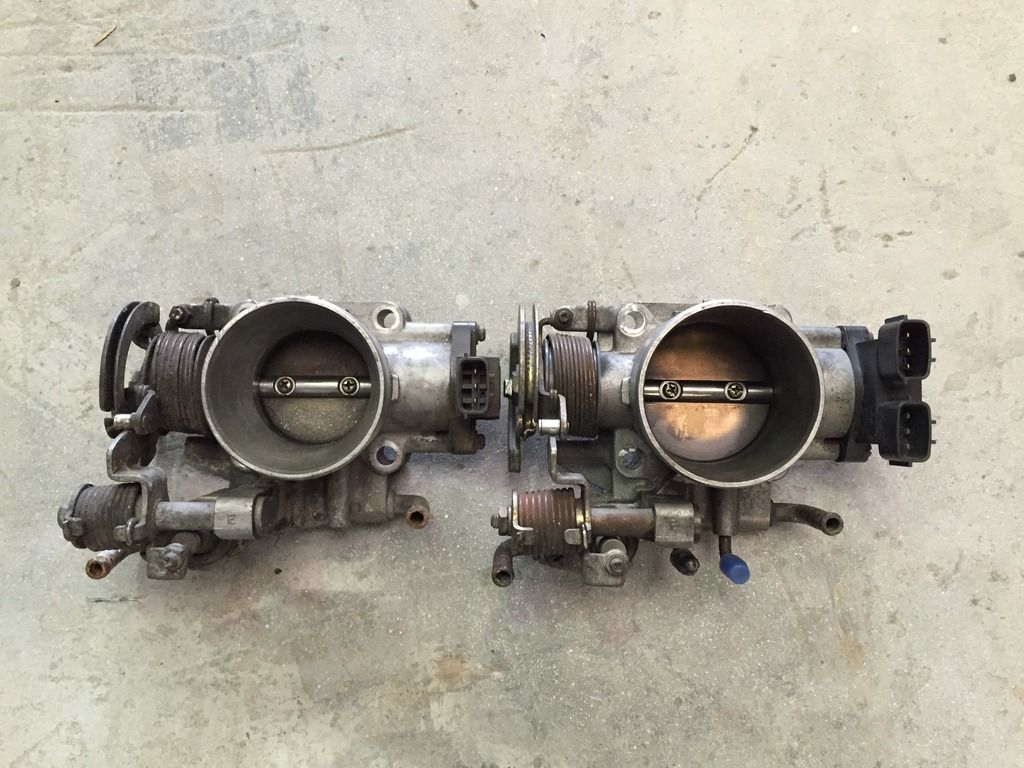

Finally got round to mounting the bumper properly with good old cable ties. Thankfully these are mainly just to hold it where it and pull the wings out a tad as the bumper bar takes all of the weight   Amongst constant sanding, I mounted the D-Max rear wing earlier with Tiger Seal so I'm hoping it doesn't come flying off anytime soon as it certainly did the trick on my old S13 hatch.     The fitment is okay, but I've allowed the end to bow a little bit in order to give clearance to the over fenders, which fingers crossed will save those annoying patches of rubbed paintwork. And here is how the interior is currently looking, with a few more hours required until I'm satisfied that its ready for primer and paint. Which brings me onto the point I'm not sure what colour the interior will be, I'm hoping to find a nice shade of a metallic Gun Metal Grey which will also be used for the engine bay too.  Amongst prep work I saw this and thought it was cool, if only I would sand the tags back to raw form once painted, but that does seem like alot of effort   Finally decided on some engine mounts too, as it was about time to ditch the god awful Japspeed mounts for something better on the fresh engine, which fingers crossed should be turning up asap. Alas - my Vibratechnics engine mounts turned up  The quality of them feels unreal and unlike any other engine mounts I've seen, but time will tell whether they are any good or not. I opted to go for the "Drift Max Pro" or the Competition version as the price difference was negligible, and a friend used to run them and appeared to praise them. The quality of them feels unreal and unlike any other engine mounts I've seen, but time will tell whether they are any good or not. I opted to go for the "Drift Max Pro" or the Competition version as the price difference was negligible, and a friend used to run them and appeared to praise them. The engine mount brackets on the SR were looking rather tired and quite frankly, ugly. So a quick freshen up was required; with an initial cost of Zinc primer after being rubbed down and degreased.  I settled for a quick coat of Satin Black as opposed to a metallic silver I had lying around, more so for that OEM look and aesthetically breaks the engine up a bit.   Whilst I was fitting the engine mounts, it was a lovely day so opted to grab a quick photo of the SR, it seems I can't quite get enough of it!  Before the car gets painted, I wouldn't mind getting the position of the fuel pump and swirl pot finalised, so any cutting can be done prior to painting. This will be my main task for tomorrow amongst further prep work, but from the initial looks an S13 fuel tank location and direction of the inlet/outlets makes it a bit trickier to ensure the lines are free from any kinks. So I finally bought the fuel pump, where I have opted to run a tried and tested setup, in regards to a Bosch 044 as an external pump, where I'll run a fresh Walbro 255 or similar as a lift pump. As with most things, the difficulty with the Bosch's is the shear number of fakes floating around, and with something as important as the fuelling, this was something I really wanted to ensure a genuine part was used. Luckily, Torques UK came to the rescue being a Bosch dealer, so it was an brainer for me, considering their knowledge of AN type fittings, I'm sure I'll be place another (yet expensive!) order in the future for a number of fittings. Anyhow, this promptly arrived;  Bosch 044 with an AN -8 inlet to match the swirl pot, with an AN -6 outlet to match the SR's fuel lines, perfect! Oh, and got a cool cradle to hold the fuel pump  Since the last post, I’ve officially graduated from university with a First Class degree which im stoked with considering the amount of work I put into the final exams. Anyhow, this kinda gave me some motivation to crack on with the car. One thing I wanted to sort out before paint was the positioning of the fuel lines as they come out of the tank and enter the swirl pot. Basically, those who are familiar with the S13 setup, they sit below the opening, meaning they can’t just go upwards without creating a large kink. So, after some thinking the best thing to do was to trim the car to suit them!   After this, it was just a case of more prep work whilst I sort out the spray gun setup and purchase all of the paint.    Found a little bit of Stonechip lying around so threw it on the front arches to see how durable it is, and turns out it is quite durable so hopefully I’ll buy a couple of cans after paint as I need to reseal below the trans tunnel as the previous owner though it was a good idea to use a black aerosol!? Quickly mixed up some etch primer for the area where bare metal is shown but for some reason it would spray nicely. Not sure whether it was due to a lack of experience or just the nature of the paint. So I preserved as much as I could before switching over to the 2K High Build Primer, where I aimed to give the whole care around 2 coats, which should allow me to wet sand with 1200 grit before the final top coat. After a while of playing with the gun settings, I was able to lay down a “wet coat” which I was stoked with. Its amazing how addictive and challenging painting can be!  Whilst this was happening, Jesse Streeter once again become my knight in shining armour and found me an S14 N/A Throttlebody which are as rare as hens teeth! Can’t thank him enough for doing this.  S14 SR20DET Throttlebody;  S14 SR20DE Throttlebody;  DET on the left, DE on the right;  You can visually see how tapered the DET throttlebody is in comparison. Hopefully when coupled with my 60mm Greddy Inlet, this should help things breathe a bit easier  (For those wondering about the TPS of the DE throttlebody. My understanding is that it came from an Auto car, hence the two plugs. But if I have gotten my facts correctly, I simply plug the loom into the top plug and hey presto, it should work!) |

|

|

|

|

|

#39 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

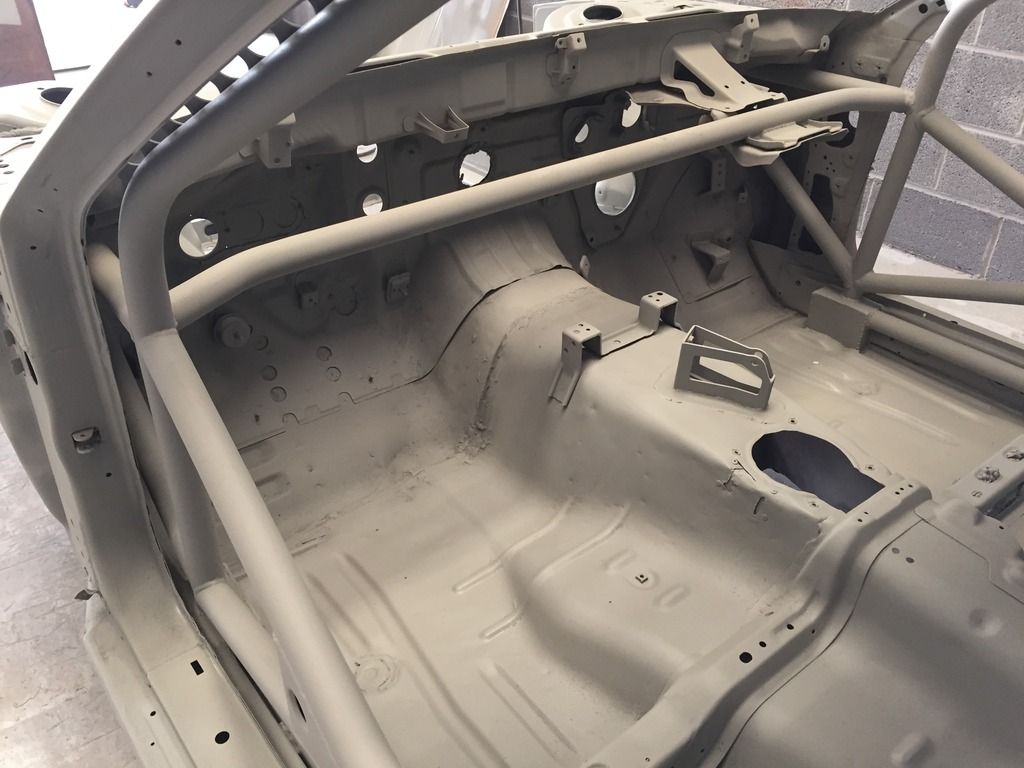

Started getting into a rhythm with the primer and made some progress, but with temperatures being solid mid-20*C it meant the paint was drying fast!

I’m overwhelmed with how the engine bay came out! Can’t wait to throw some colour down on it, but kind of nervous at the same time              And this is how I left today, everything that should be in primer, is in primer and luckily enough as all of the primer is now gone!  My plan is to get the rear 1/4’s black tomorrow, so the rear overfender’s can be riveted on before the whole shell gets painting. This should mean even if I blow a rear fender, it’ll still be black behind it to try and make it more discreet if you can ever make that discreet haha. My buddy sent me my new lenses which I super excited to get on, pretty much a “must have” on the Brick headlights in my opinion, as the glass is a bit dated. I cant describe how anxious I was doing this job and these headlights are NOT cheap and were pretty mint too! :’( Went slowly with the heat gun and slowly tried to pry the glass of once the glue had softened up.  Cleaned the remaining glue out of the casing ready for some fresh Tigerseal! After a while the job was done!   Pleased with the outcome, just have the other one to do but I’ll do that next weekend or something. Im not sure whether I was just a bit heavy handed with the tigerseal or it is the nature of the lenses, but it looks a bit messy if you look closely. I’ve got some black vinyl lying around, so I’ll maybe replicate a border type ordeal similar to the OEM glass, and something Daze did with his (Albeit on S14 headlights). This should make them much neater up close, but as they are, they look so so good! So things can only get better!  Ordered up some fresh S14 LCA balljoints earlier (MOOG K9820) , and my fresh OEM front wheel bearings should be here anyday. I just want this car built with fresh parts, ready to go attack any track that takes my fancy! Fast forward a few days - I had a little package turn up    A pair of brand new OEM Nissan S14 front wheel bearings. A friend mentioned these retail around £450+ each from Nissan which is crazy! Thankfully, a buddy of mine helped me get these in at a stupidly good price. These were cheaper than the OE copies/versions I've seen for sale here in the UK. Started playing with the black paint today, and took me a while to try and adjust on how to spray it, as it seems to run alot easier. Luckily the runny rear 1/4 will be hidden anyway, but the drivers side came out quite nicely after adjusting. It appears to have some orange peel, which suggests I may need to add some thinners to the mix, or play with the pressure but that'll be my job for Thursday i'd imagine as I need to wet sand the car before I can proceed.   I've riveted the rear fenders on for good now, whilst the fronts are merely placed there to help make sanding them a little bit easier. Who knows, maybe this time next week it may be all black?! |

|

|

|

|

|

#40 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

Well, I spent some time over the weekend painting so there’s no surprise there eh?! But the crucial factor is that the interior and the exterior of the shell is now one colour

So during the week I set about splitting the other headlight in order to fit the new lense, wont bore you with many pictures but it was the same process, just that this one was a tad harder to split for some unknown reason, but I’m stoked on the outcome!  I grabbed the paint gun and had a quick mess about to get used to the paint again, and started on the interior. Note to anyone, painting the interior of a cage with a serious cage is not fun, its so hard to try and cover every little spot with a gravity fed gun. Looking back, I could have done with a smaller touch-up type gun to get everywhere but I soldiered on the best I could. After a few hours, and 2 solid coats, this was the outcome;      There are a few tiny places where I couldn’t manage to paint due to the awkwardness, but hey. I’m happy with the outcome! So the next job was to move onto the exterior, which I found much nicer & easier to spray. I’m just relived the car is almost one colour.          I cant express how happy I am with the outcome once looking back. Does it have a professional finish? Nope. Is there a tiny tiny run on the rear ¼? Yup. Is there some orange peel? Of course. Is it black, sort of shiny and presentable for a track car that will have bumpers flying off? Absolutely YES! There are a few things I’d change if I were to paint it again but as a first proper go (my old car really was a half arsed job so doesn’t count :wack: ) I’m pleased with the outcome. I still have to do the door, bonnet and aero but I have around a litre of paint left. So I’m thinking of grabbing another 1 – 2 litres so that I can start and get everything covered. I went down to the car to see how things have dried, there’s a few specks of dust in the paint but like I mentioned above, I wasn’t expecting a shown and shine finish for my first attempt, but hey, I gave it a good go  Quickly mounted the lights up and the boot, the rear garnish under the lights could do with another coat which I may do, but as a whole, I’m pleased to say its getting there. Quickly threw in the hydro too, just to give me a warm, fuzzy feeling haha. (Although take note kids, hydro’s can be bad your driving style!  ) )       So now I just have to paint the other little bits, and the engine bay  I’m hoping to start work on getting the bellhousing machined on the Z33 gearbox soon, in order to be able to complete final fittings on the engine and get everything in place for good. I’m hoping to start work on getting the bellhousing machined on the Z33 gearbox soon, in order to be able to complete final fittings on the engine and get everything in place for good. |

|

|

|

|

|

#41 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

Here's a few pictures of today's progress. I wet sanded the door and skirts back and gave them another go!

Outcome is much better, still a tad orange peel' and some dust (after drenching the surrounding floor!) but after a polish I'm sure they'll come up a bit better. Mirrors came out quite nicely though       Hoping to spray the front wings, bonnet and both bumpers tomorrow. Then towards the end of the week, circa Friday, the engine bay may finally be in a colour! Started assembling the rear end and the doors yesterday and was stoked on the results!   Really can't wait to sit in here properly, but that won't be for a while yet unfortunately.  I threw on the Silvia light garnish after giving it another coat. I'm quite glad I did to be honest, it has a much deeper shine than before which is awesome. Cleaned up the rear lights as they had a load of sealant from the previous owner.   The original plan was to tint the rear lights all red, but after seeing them on yesterday I fell in love with the 50/50 look. Jeez, I'm so indecisive at times! Yesterday afternoon I set about painting the remaining bodywork; the bonnet, wings and both bumpers. Progress seemed okay, until the front bumper fell off my makeshift stand and hit a wing! I wasn't sure whether to laugh or cry, but thankfully it was the first option! I haven't seen how they have dried yet, so hopefully I'll find out in and hour's time or so. If all has gone well, I'll be starting the engine bay this afternoon or tomorrow. The colour I have chosen will not be easy to paint, but I'm set for the challenge   |

|

|

|

|

|

#42 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

After I finished painting the wings, bonnet and bumpers, I threw the wings on during the following day to see how the finish looked in comparison to the doors and body.

Believe it or not, that is the front wing the front bumper fell into during paint. Thankfully you can't notice too much, and being fibreglass I'm sure they'll become a disposable item anyway  Once that was done, I got around to reinstalling the slats into the top vent of the bonnet and reassembling the Aerocatches;   On to the fun part which Leno suggests, the engine bay is finally in colour. So I took a picture for comparison purposes to show the stages  Ive chosen to run a Candy paint for the engine bay to make a feature of the engine bay, and a colour which I feel will tie into the car very, very well. (Hopefully!) Candy's are notoriously one of the hardiest paints to spray, which at this point I wasn't sure what I had gotten myself into was for the better or worse! A candy is a type of translucent paint which is kinda cool! But they require a base, where I chose Silver to give myself a bright, vibrant finish over a darker coloured base i.e. Gold. Here's the base;  There is not specified amount of coats, but I ended up spraying 2 coats of base as the primer was already quite light to begin with;     It looks quite cool in this colour, but isn't what I quite had in mind :wack: The candy I had chosen was Candy Apple Red! I had gotten this idea of my father, and the hot rod scene as they love spraying Candy paint. What better way to mix the generations and bring a bit of spice to the old Silvia! So after the first coat of candy, the engine bay was looking like this;  It was very bright, and also still very see through given it was the first coat. I bought 1 litre, which was exactly enough for 4 satisfactory coats which seemed like an ideal number between a very light candy, and a very dark one. After the 4 coats;   You can see how its gotten visually darker with a gradual build up of coats. The next stage was to apply 2K lacquer in order to seal the base and candy, and to give it the all important shine. I had never sprayed lacquer before and found it was well too easy to get the odd run here and there, but nothing large and not instantly noticeable. After the first coat;  After 4 coats, which I deemed enough to protect the paint, give a reasonable paint and well, thats all that 1 litre of 2K lacquer and hardener would allow me to cover :wack:    Lacquer was still wet here, but you get the picture;    Went down the following morning to check the progress and everything seems well, I'm going to leave the lacquer longer to make sure it is fully cured before bolting the front end on. Plus I'm in no rush this weekend to get this bolted on. Trial fitted the rear windows again to gauge how to fit them. Initially I was thinking of small black rivets, but may go down the standard bonding route for a much cleaner look. The other factor in this decision was attaching the roof spoiler, where rivets could potentially mean the spoiler wont sit entirely level but I'm not too sure on that so may play it safe and just bond them in.     And that's how I left the car today around lunchtime. I can't express how chuffed I am with how this car is turning out. There's plenty of imperfections in the bodywork and the engine bay, but as I've said before I'm not bothered as its been a huge(!) learning experience and turns out its quite addictive haha! Time to start ordering the small bits and bobs to start making things come together. Im hoping a friend will swap the front LCA balljoints out this week, so that means it may be back on the floor rolling soon which I can't wait for. I need to start thinking about splitting the gearbox and getting the bell housing machined in order for the conversion plate. Once that's done, I can begin to think about dropping the engine in, which is a day I seriously can't wait for. Just think of that gold valve cover against that candy red, oh my!! |

|

|

|

|

|

#43 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

tarted assembling the front end today, although the front bash bars will come off in the future for when the engine goes in, but its a case of 12 bolts to remove both of them. (Offered up the Equips just to gauge how awesome it'll look

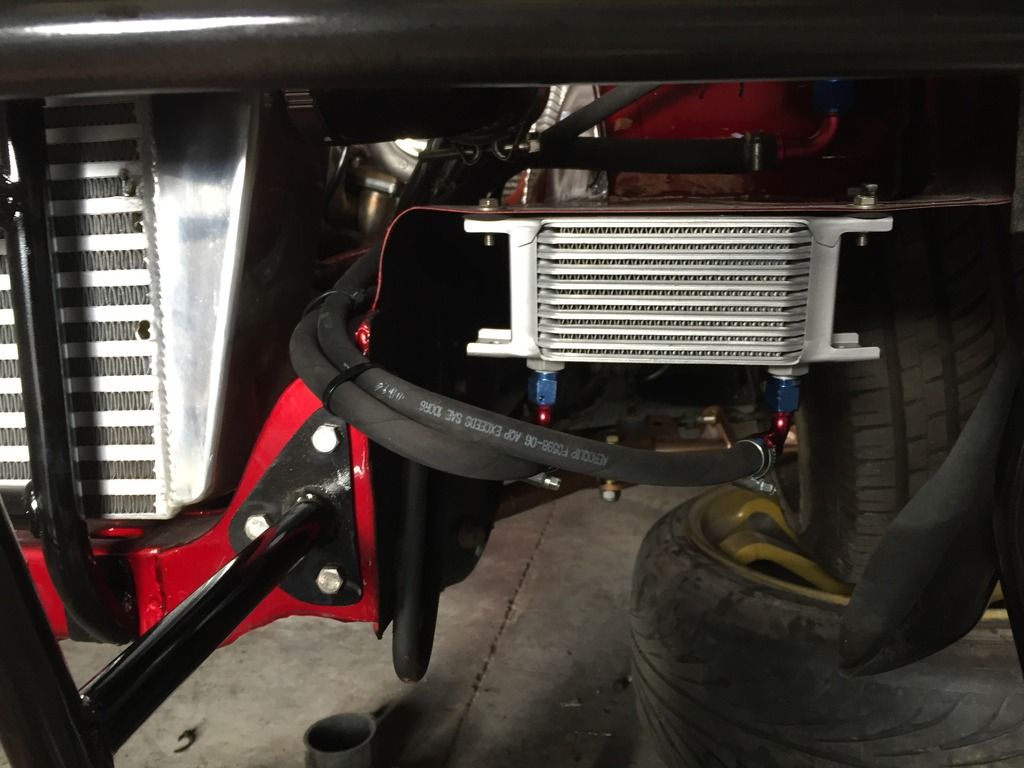

) )  I just love how the Candy comes through on that bottom crossmember!   This week's tasks hopefully mean it'll be on the floor, on all 4 wheels which I can't wait for. Hopefully a friend (diamondsink) can machine the bell housing for me, just have to make sure it fits within his machine, as the Z33 bellhousing is rather large! If it does, I may strip the box down tomorrow and hopefully make sure all the gears have teeth on them. So after the last update, a few of us were speaking about the rear traction rod length, where common practice leads to people replacing them, but keeping them at stock length. A friend explained how the length determines the dynamic movement of the alignment throughout the compression stages of the rear hub (I think I have that right haha). I was supposed to sit down and have a look for myself, but I kinda got lazy and my friend told me the length he extends his to, and considering he’s driven a fair bit, I trust him! The interesting thing that caught my attention was how the rear wheels suddenly sat;   Time will tell what difference this will make to improving the rear end, but considering the extensive changes between my old 13 and this car, I may not be able to give a direct comparison as so much has changed, it’s literally a whole different car!  As im running a swirl pot and fuel pump in the boot, something I always want to make up was a firewall of somekind, so after quickly knocking up a few idea’s, I just went and made a dead simple one.    It wont be up to BDC and other motorsport regs as the rear isn’t completely sealed off, but IF that time ever comes, im sure I could make another firewall that would be compliant. But for now, if something comes loose in the rear, there’s something inbewteen us :thumbs: Plus, it should help dampen the noise the 044 may create too. After following Daze’s car closely and looking at his power steering setup, it made me want to run a power steering cooler to prevent the fluid from boiling over. After looking at his setup, a -6 cooler was needed. So after trying to avoid buying an unnecessarily large core, I managed to find this;  Perfect! |

|

|

|

|

|

#44 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

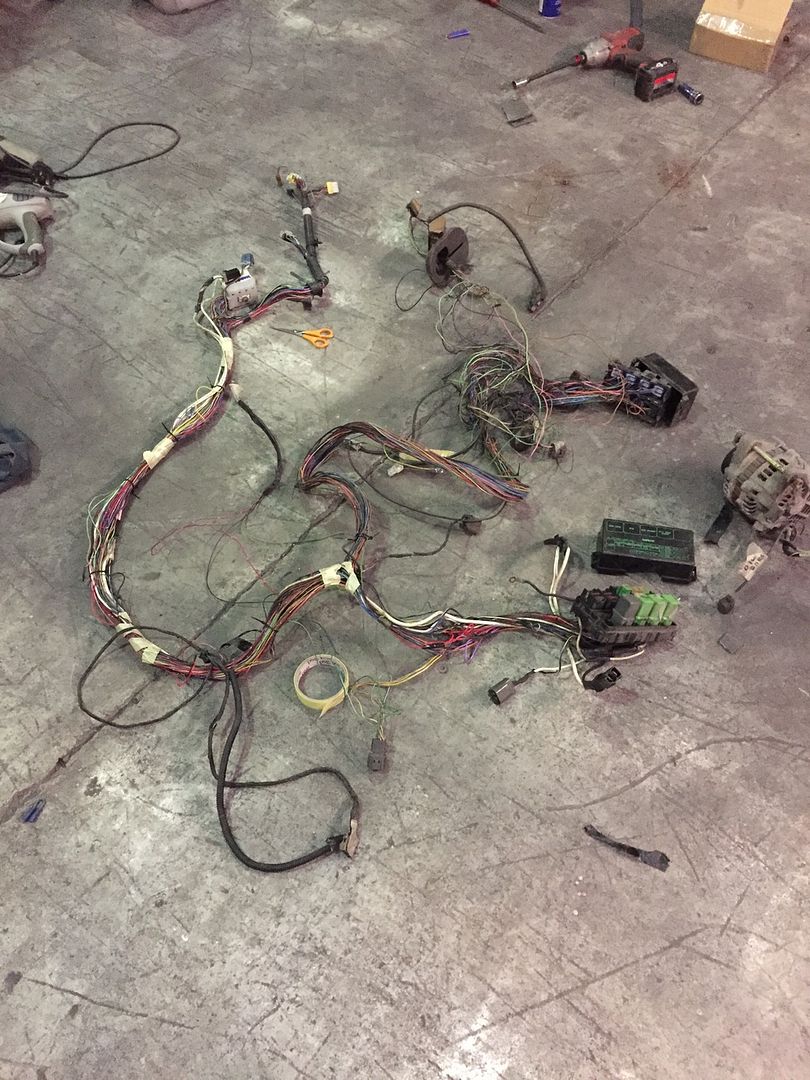

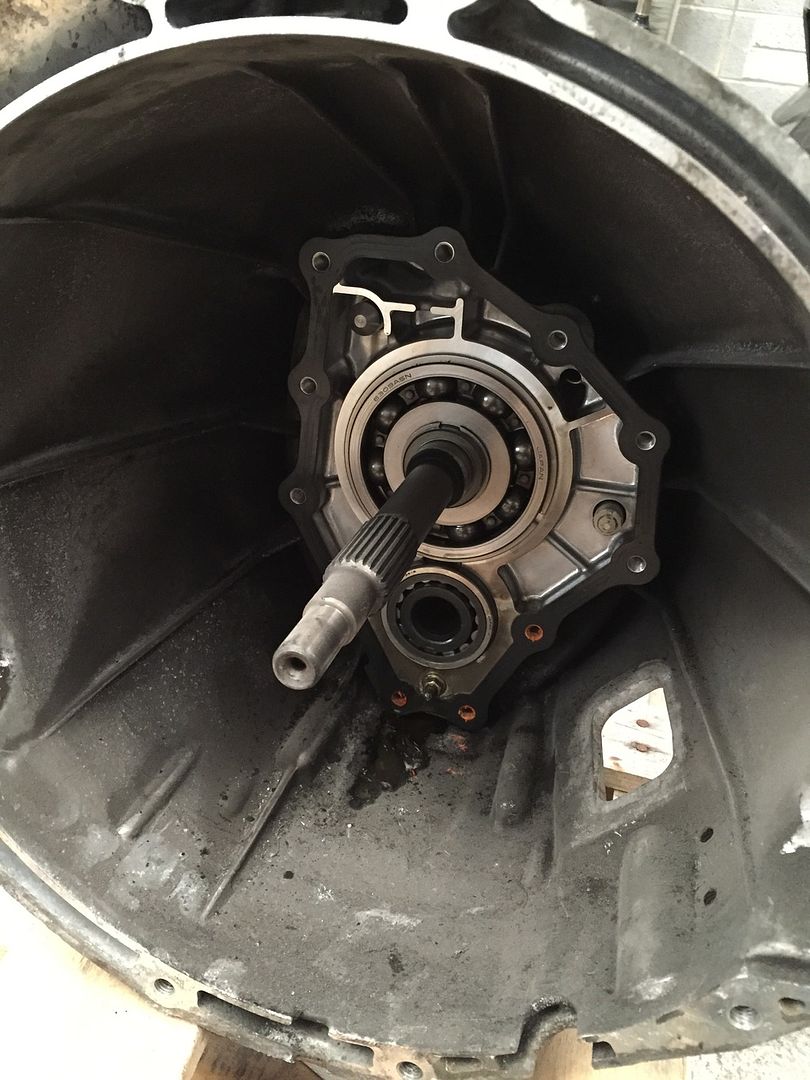

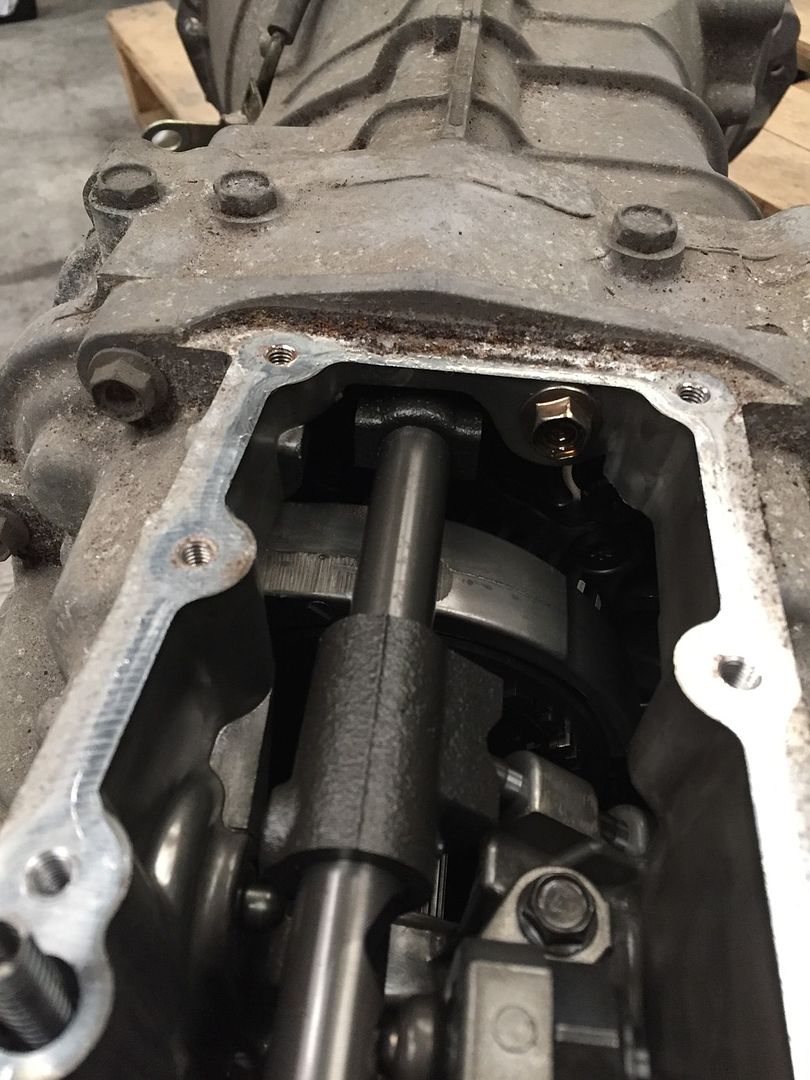

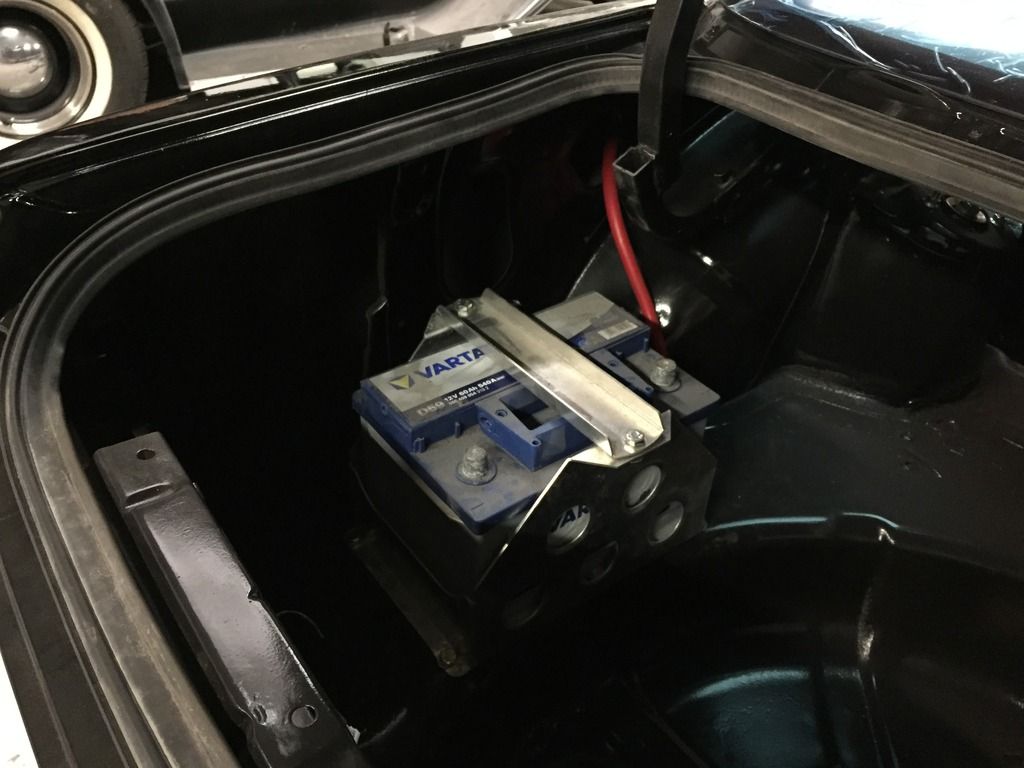

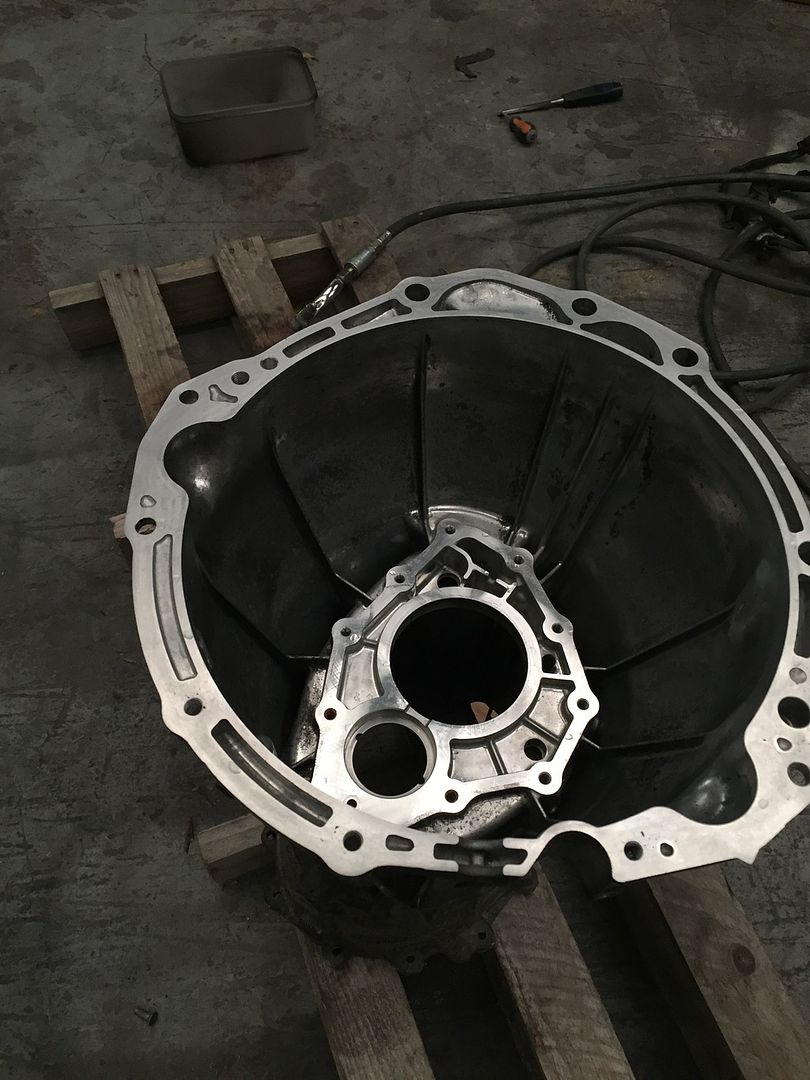

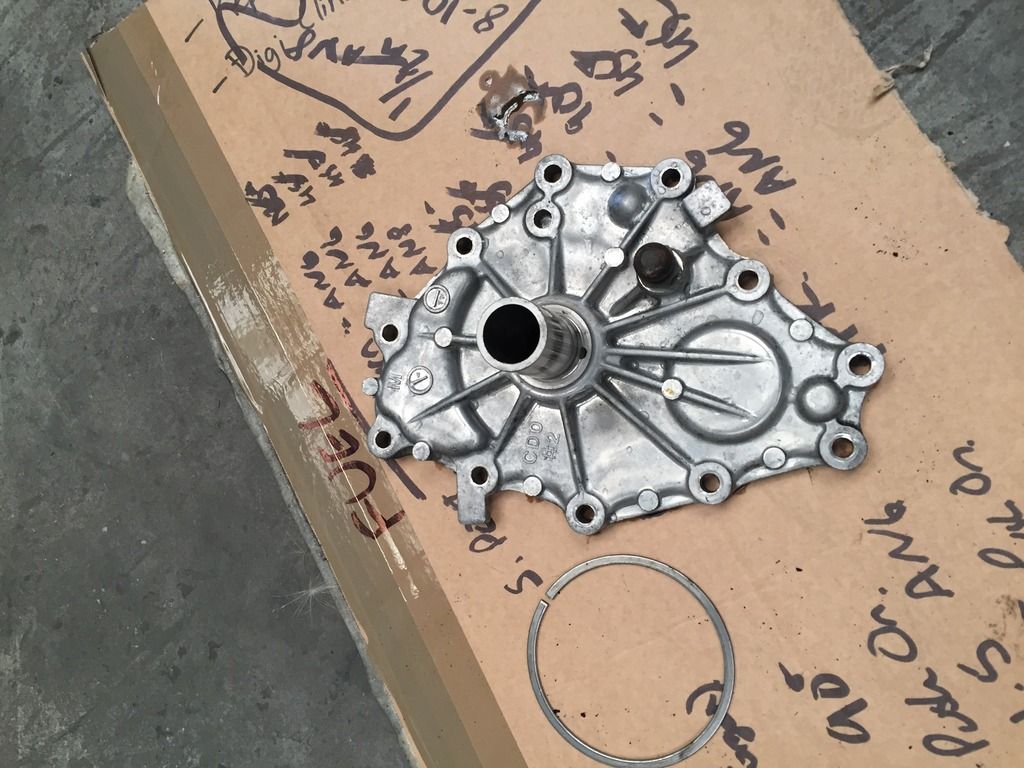

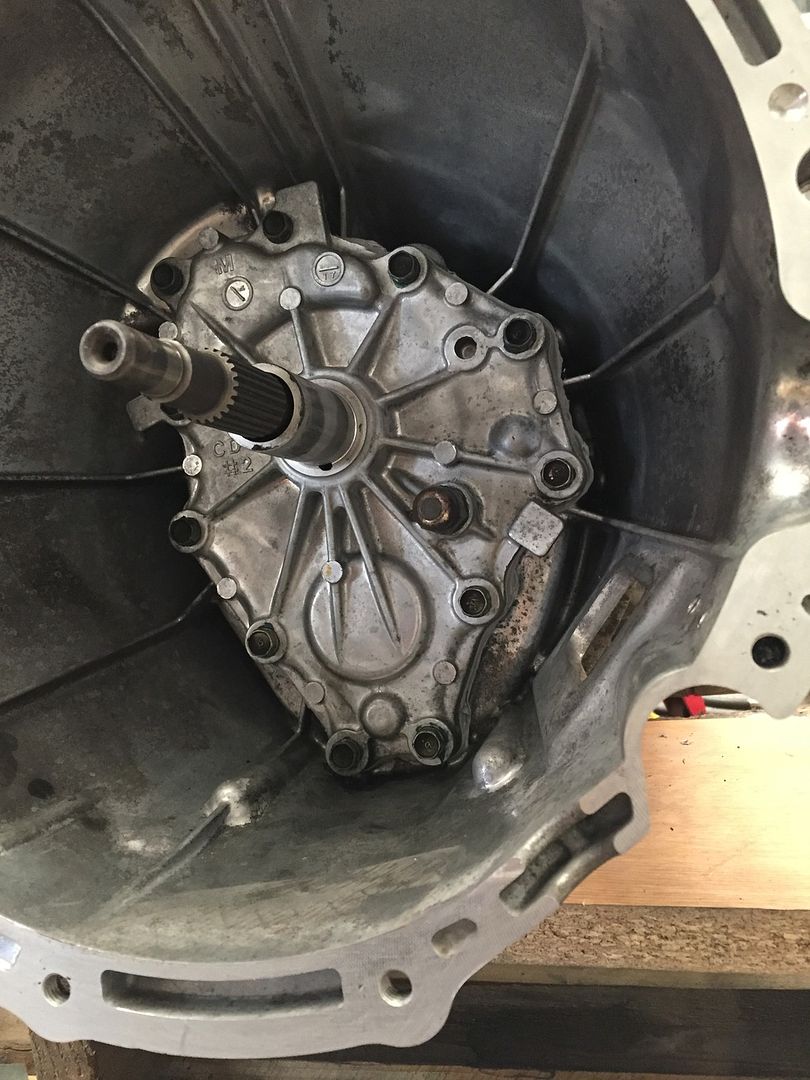

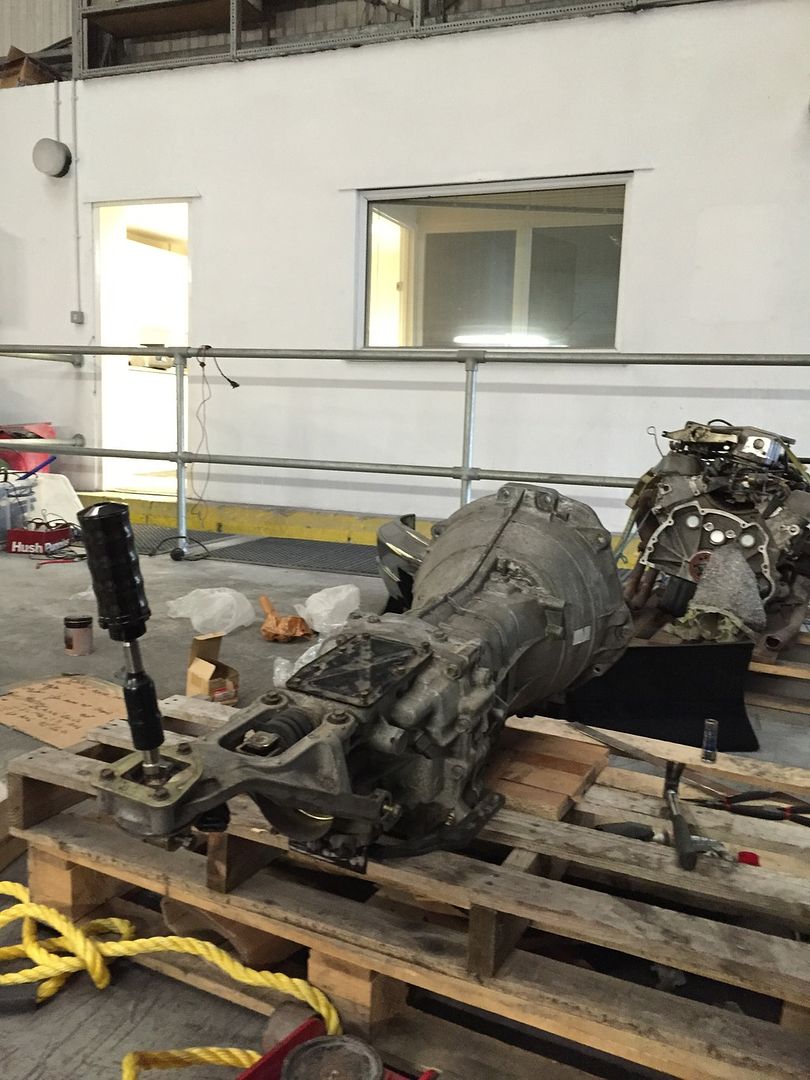

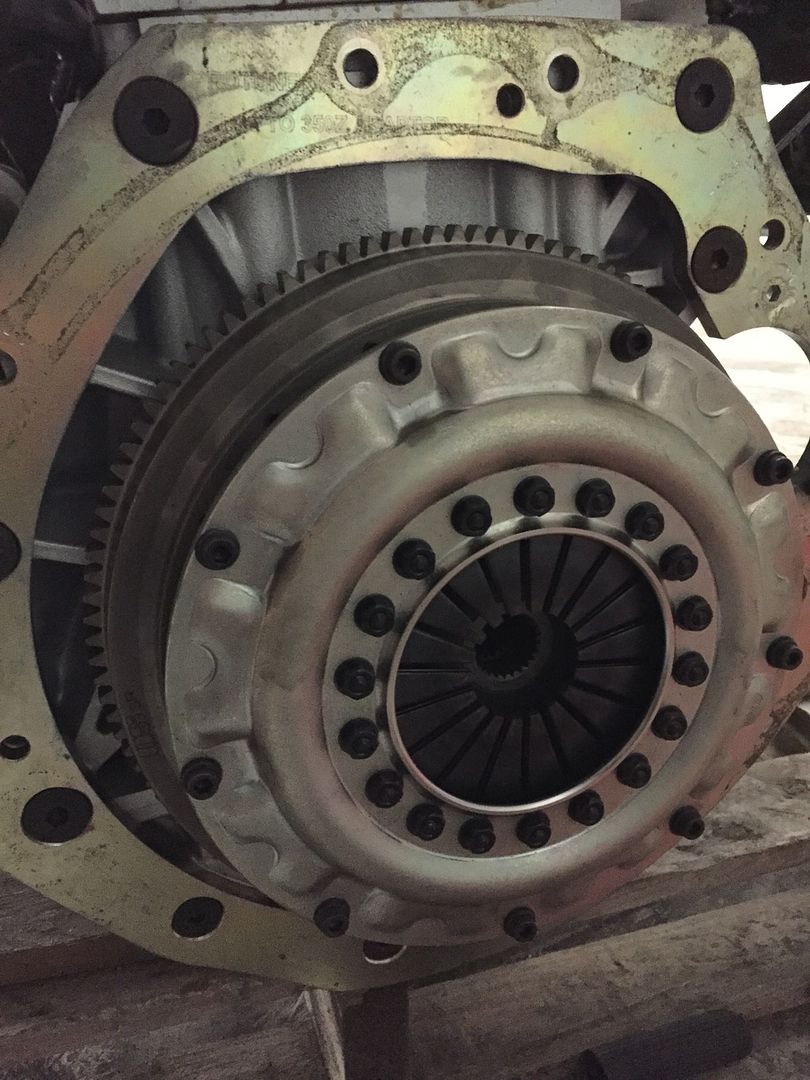

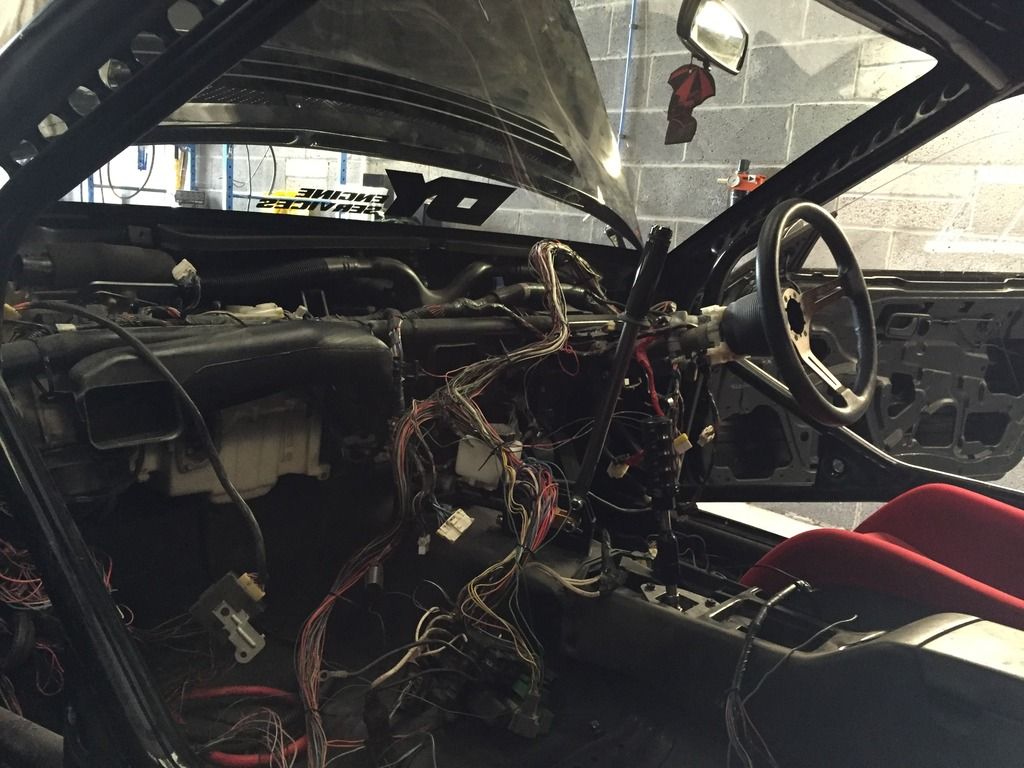

Since the cage went in, everything was painted it was now time to start the assembly phase. So first things first, the heater matrix. Huxley said to me I’d never get the end heater matrix/core in due to the triangulation of the cage to the front struts, challenge accepted!

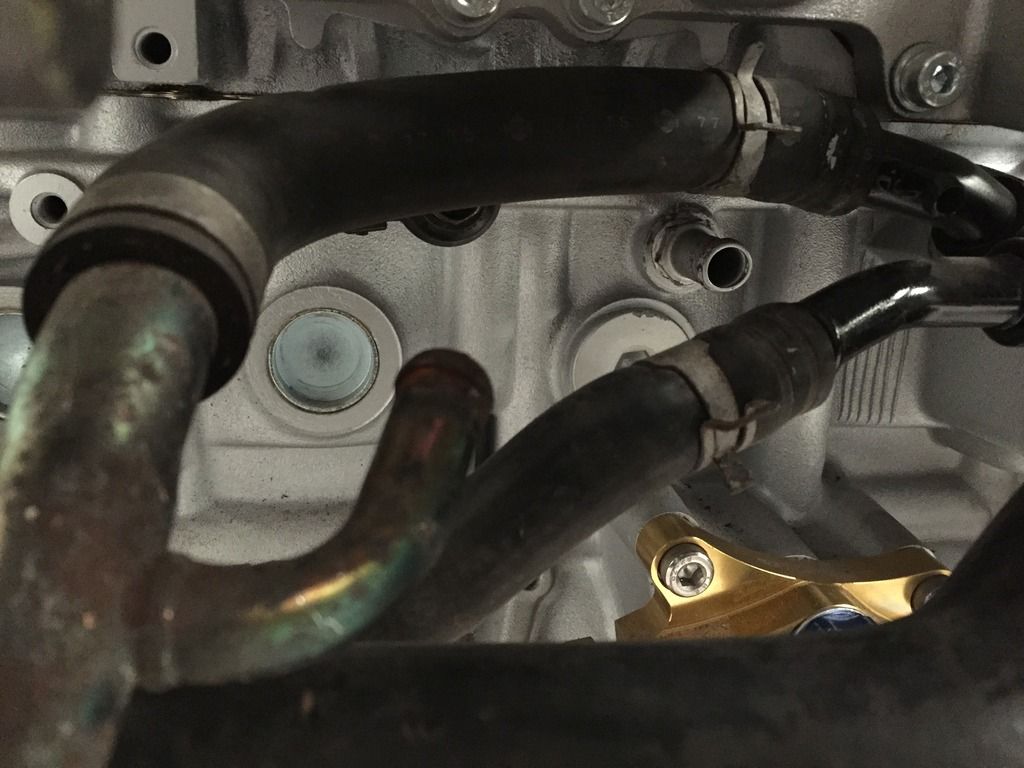

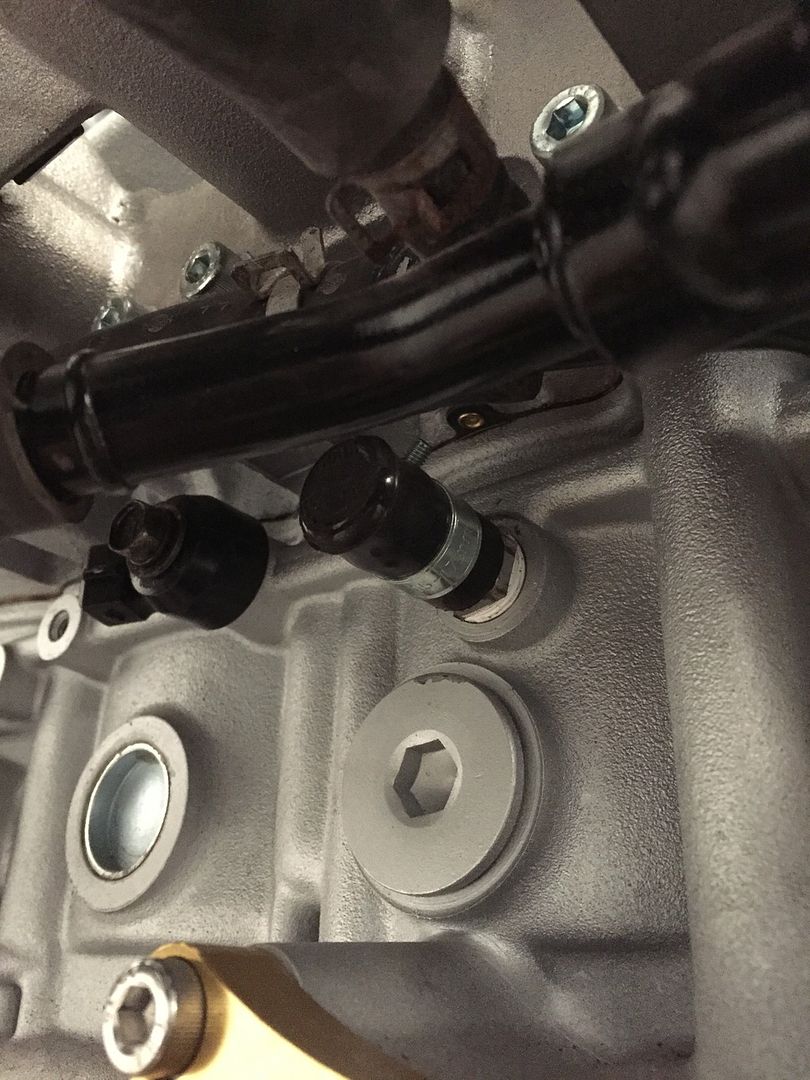

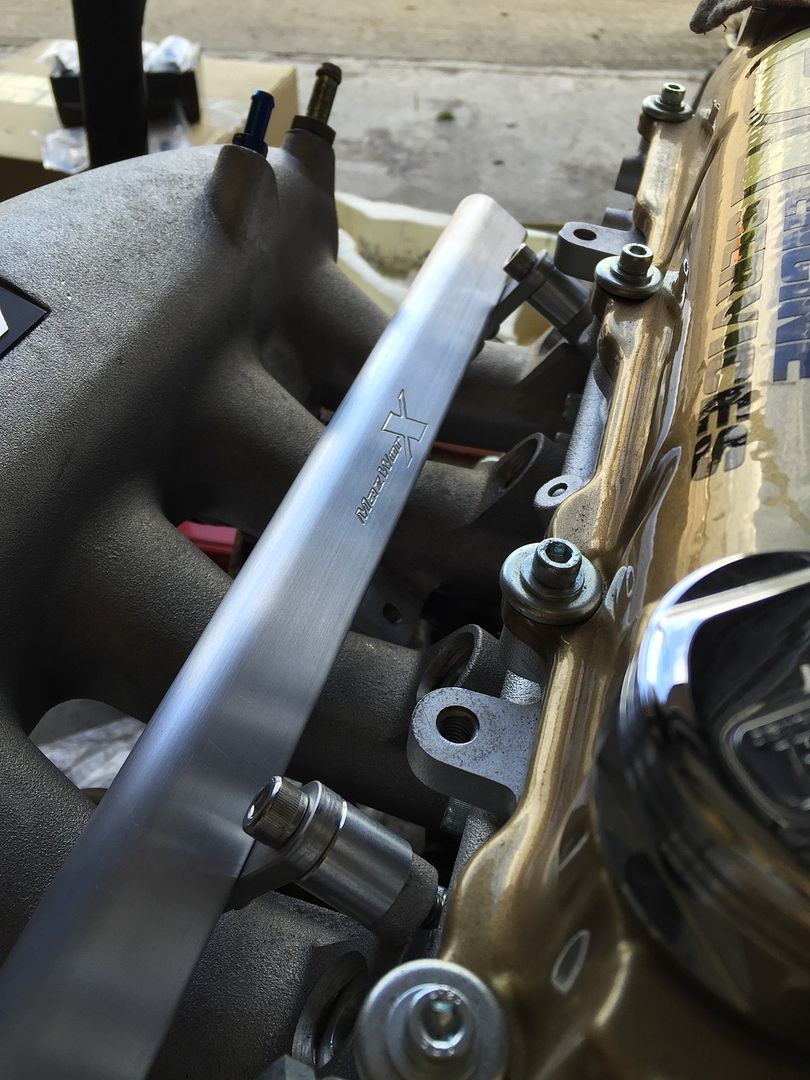

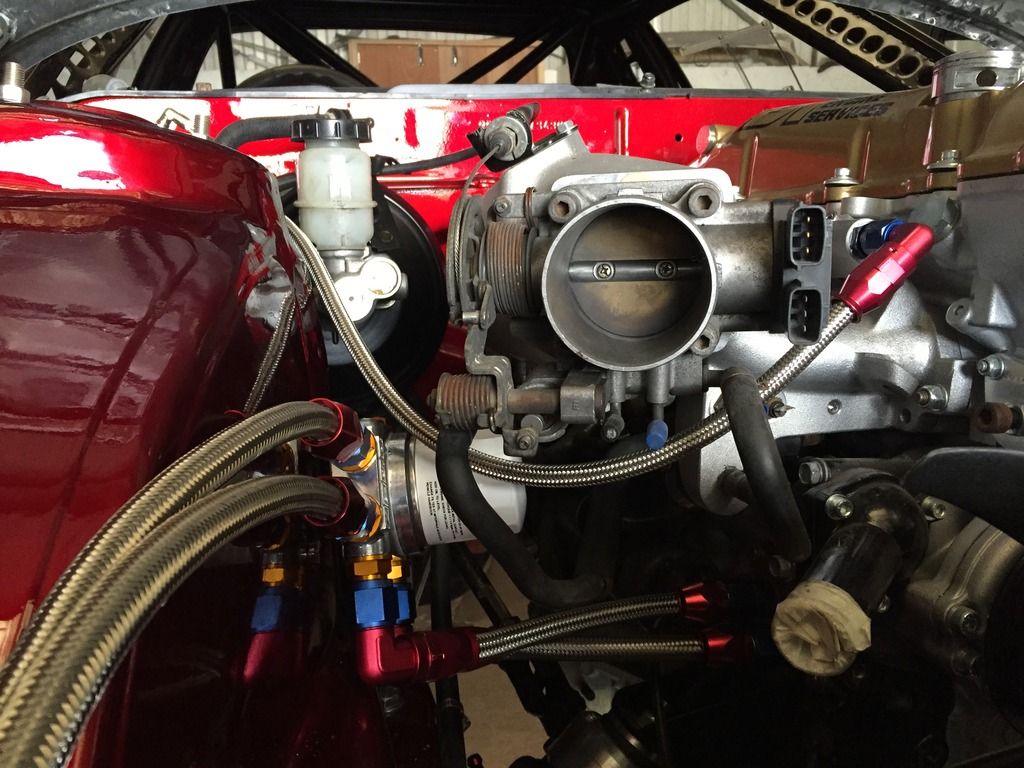

After a few nudges here (with some added cuts), and a kick there it went straight in! So atleast I can retain a fully functional heater setup  I started speaking to Norfy about my wiring, as the car will have the bare essentials as its not likely itll see the road in the near future. So after speaking to him one evening I began cutting down this mess, and had a date night with the car whilst I was there. (Im 21, I should be out drinking, partying or whatever my friends do! Nope, im just sat there with a car that tests my patience constantly  ) )  Interior harness in :thumbs:  Now for something I wasn’t really looking forward to. For the SR/Z33 gearbox conversion, with the use of an adapter plate you can either chose an S15 clutch and flywheel and leave the bellhousing, or use an S14 clutch setup like I have, and get the bellhousing machined. So here’s what I started with, 1x Z33 CD009 gearbox.  First things first, remove the front cover and 2 circlips;   Now its time to remove the obvious bellhousing bolts that essentially sandwich the two halves of the gearbox. Luckily a bit of searching online the day before meant I didnt forget this little one that’s hidden under the plate that covers the shifter mechanism;  So now it should be ready to simply pull the bellhousing off. After softly prying the bellhousing, it began to move and then stopped. After pulling my hair out a friend told me about a small 10mm nut that holds the windage tray (?) behind where the front cover usually is!  And then, POW!   Its hard to get a sense of scale from pictures, but the size of the gears in comparison to a small casing gearbox i.e. SR20/CA18/RB20 is just phenomenal. Oh, and it’s the first time I’ve seen inside the gearbox, so its nice to know all the gears have teeth haha! The bellhousing itself creates a problem due to the sheer size of it, meaning now any old machine shop will be able to mill the bellhousing. Luckily enough my friend and engine builder came to the rescue and he knew a guy that could  Anyway, back to the car. I relocated the battery to the passenger side of the boot. I thought about having it behind the drivers seat like I did in my old car, but I suppose it could become a deadly object should it come loose, so in the boot it went. And luckily enough it seems like the BMW 540 battery cable I used to use still reaches the dashboard area which is where im hoping to run the front chassis/engine bay loom, ideal!  I finally installed the S14 N/A throttlebody too, something that doesn’t look very fancy haha    For those that don’t know, when installing the Tomei Oil Block, it ditches the OEM oil/water element, which means the original heater hoses don’t exactly work. After a speaking to a friend whos done the same thing, I went a similar route, which was to simply block off a water way on the block, and the associated connection on the heater side;   Simple, but avoids having a hose that is massively kinked.  Surprise surpise, I came across another issue, something that shouldn’t have really happened in my eyes. Greddy provided tabs with the inlet to retrofit the standard fuel rail, but for some reason my fuel rail seemed to pull the top of the o-rings as its get bolted down.  A solution could’ve been to weld some tabs on the rail to other mounting points to pull the top of the o-ring back in. But I cant weld so that option is useless to me. So a friend hooked me up a killer deal on a Mazworx top feed fuel rail and a set of injector Dynamics 1000cc injectors, a bit overkill for the TD06L2, but definitely future proof should I fancy a change to something a bit bigger and begin to push the engine. I know I whore the engine off wayyyyyy to much, but I just cant get over how good it looks in the flesh! Suppose its down to this guy though   |

|

|

|

|

|

#45 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

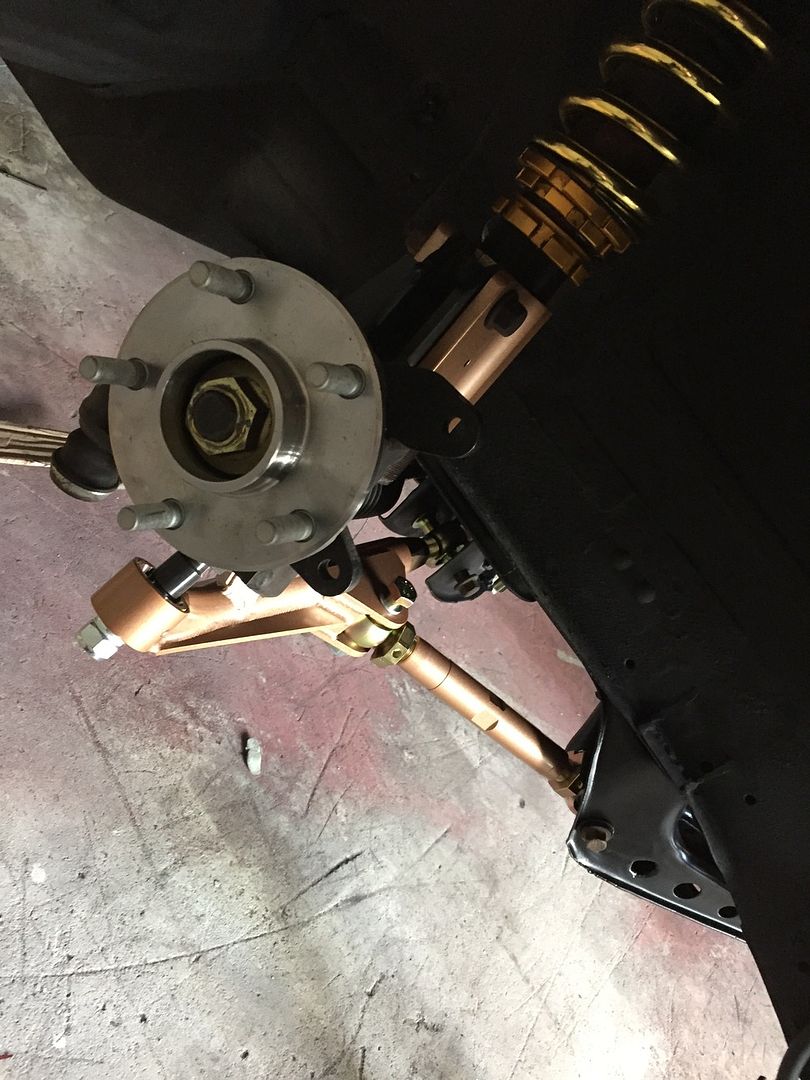

Next, I began to attack the front end. Quickly mocked the coilovers up and wound them down a bit from where they were to compensate for the Geomaster’s but to allow for a further drop to reduce some of the reverse rake I had.

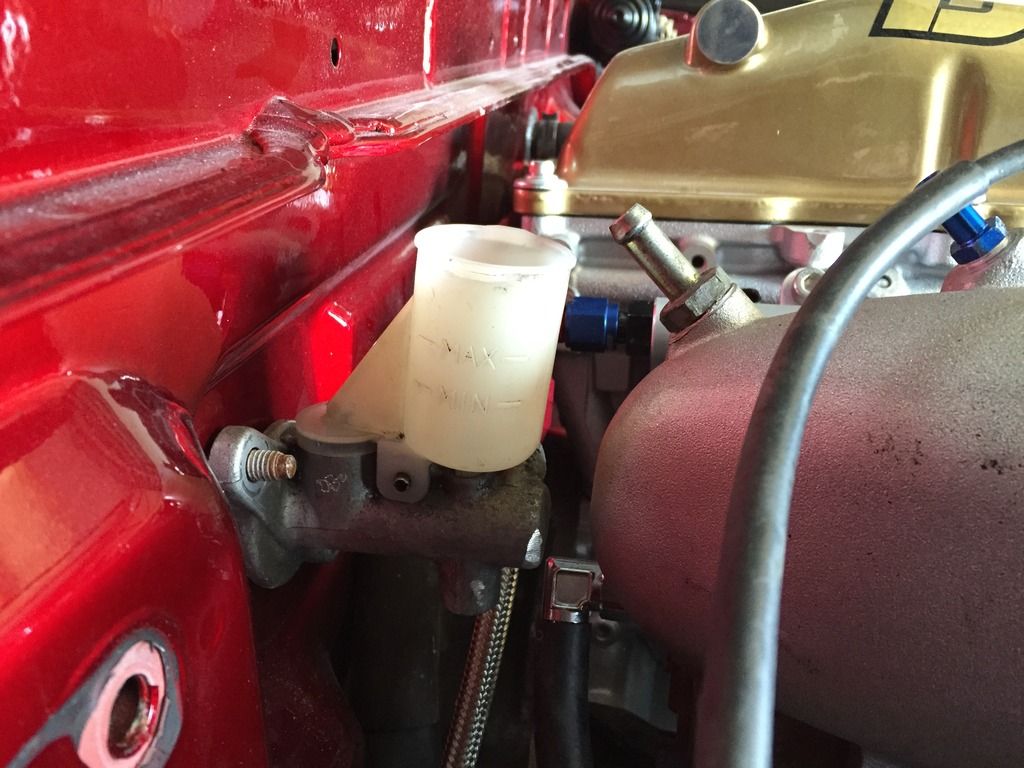

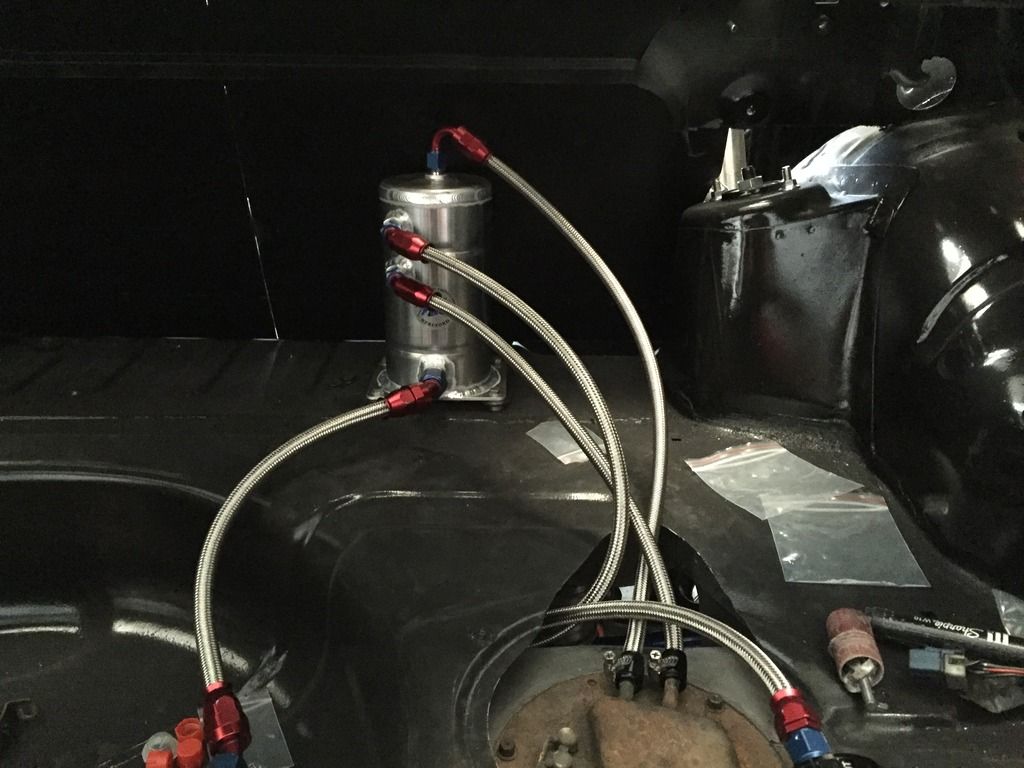

You’d have thought these 2 parts would bolt together nicely, wouldn’t you? Nope. It seems the mounting brackets on the coilover are just chunky enough that the bottoms foul on some welds on the Geo. So I slowly ground/chamfered the bottom edges of the coilover brackets, which luckily enough didn’t take much until both sides just slid on :thumbs: (It was horrible taking a grinder to brand new coilovers!  ) ) I quickly threw in the Defi water temp sensor whilst I was playing around with the engine, such a neat idea to have the sensor here, rather than cutting into the top radiator hose.  I went to go an tension the power steering pump, but upon its maximum adjustment the belt was still slack, great. Quickly dropped Tarrks an email and it seems it was simply an honest mistake of the wrong belt being shipped to me. Phew, atleast it’s a simple solution. Seeing as they are based in Australia, It didn’t make sense to ship a generic belt across the world, so they’ve given me the part number of the belt I need which doesn’t cost much at all. Thumbs up to Tarrks though, speedy and helpful response :thumbs: Something that I’ve always wanted to do was to ditch the OEM eccentric bolts on the rear alignment arms. This is something a few of us spoke about before, where we talked about getting something made up. But seeing as nothing came of that, I went and bought GKtech’s kit for the S13 setup;  Before;  After;  Comparisons between OEM and the GKTech eccentric lockout kit;  Gave the alternator a quick clean, and quickly slapped some paint on the pulley (I mean quickly slapped haha. I was in a rush, and the paint on the pulley before was dreadful. Luckily enough itll be hidden anyway  ) ) Threw the servo that the PS came with on, which to my understanding is an ABS servo due to the additional thickness? The reason I’m favouring this servo is that my old one was full of a dark liquid, which I can only guess as break fluid, suggesting my old BMC was leaking. No biggie, as I’m planning on switching BMC’s due to the new brakes anyhow.  - - - Updated - - - I mounted the Tomei FRP too. I wanted it out of the way, but still easyily enough to read the gauge. So I chose to mount it beside the brake servo;    Looks quite smart in my opinion. I did try to follow the angle of the gusset too  Next up was to mount the power steering cooler. My idea was to mount it underneath the passenger side tub/arch like so;   And this is why;  As I wont be running any lights in the bumper, the cut outs give great access to the core, meaning it’ll actually be kinda efficient I guess haha  I finally mount the swirl pot in the boot, using rubber washers and a spacer to keep the pot level;  Installing that on my own was not fun, trying to be above and below the car at the same time tightening the nut and bolts was hard work haha. I was originally going to mount the fuel pump directly in front of it as the pump needs to be level or below to get sufficient fuel from the swirl pot. But a friend who runs a swirl pot advised me to run it slightly lower than the swirl pot, as gravity will aid feeding the 044 fuel, and 044’s hate having to “suck” fuel apparently. So I went with his advice and mounted the pump in the wheel well, which lets be honest, wont ever be used for its intended purpose ever again.  |

|

|

|

|

|

#46 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

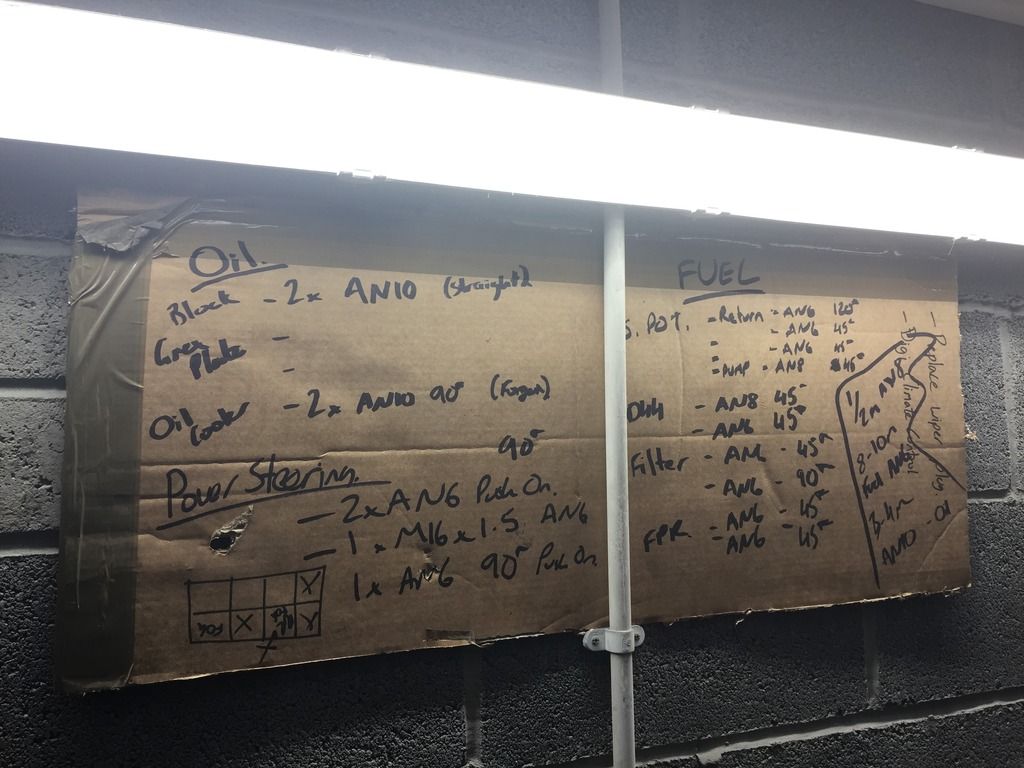

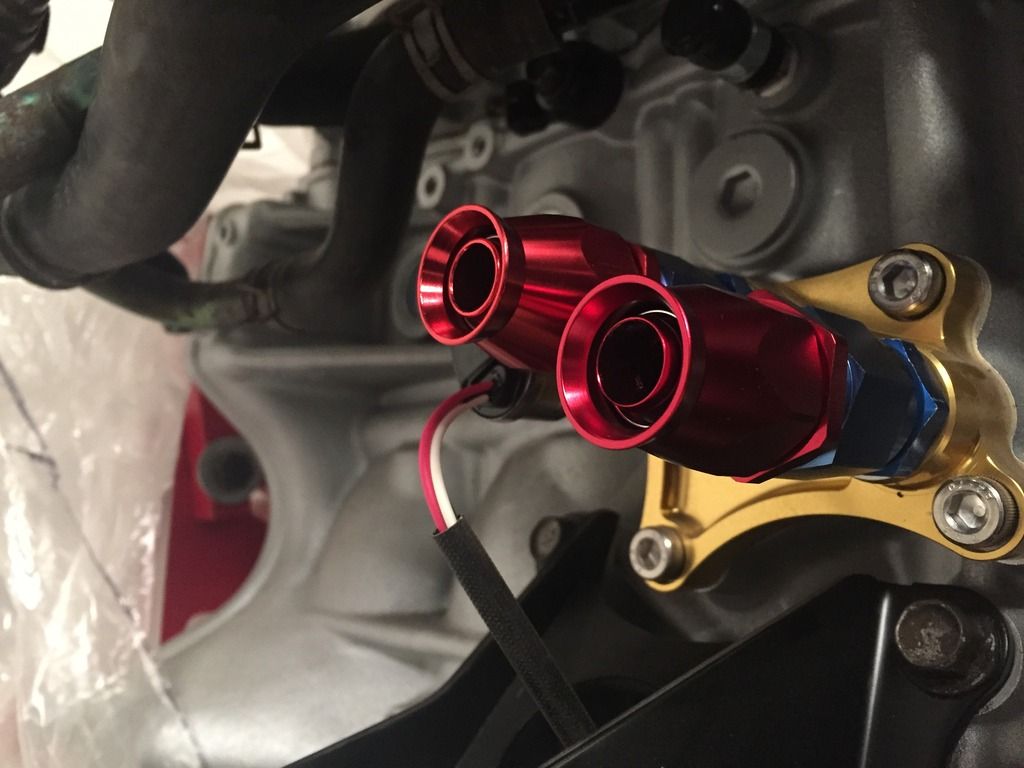

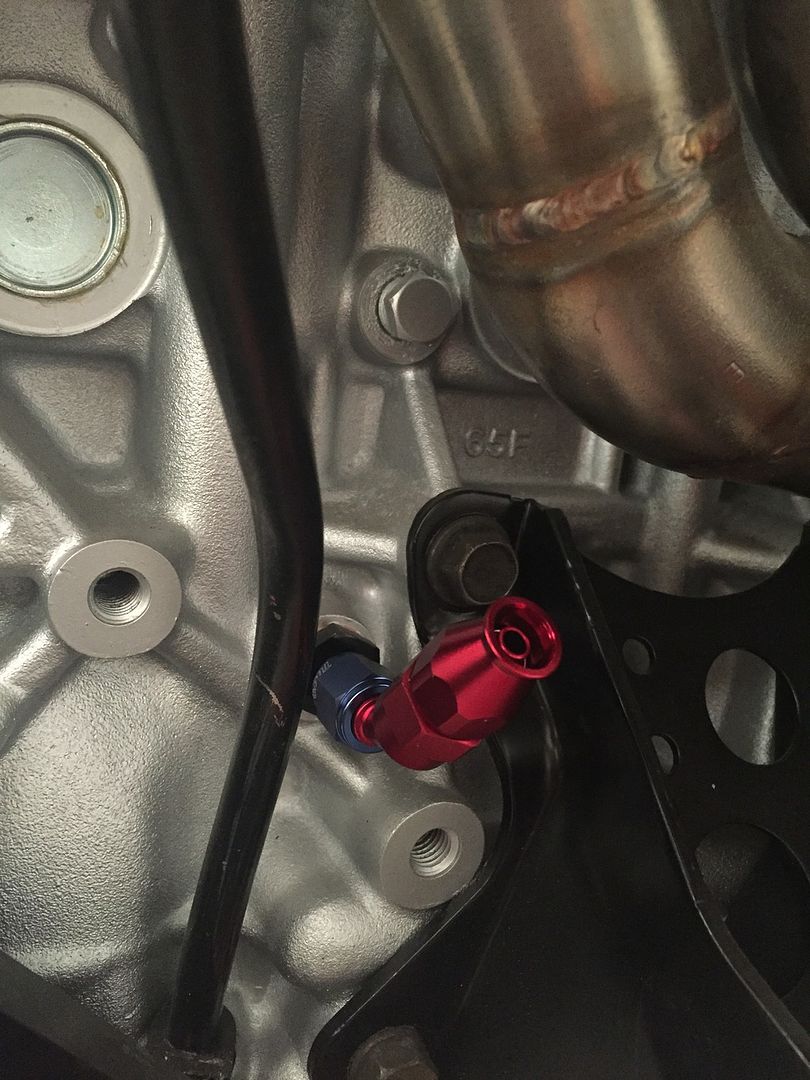

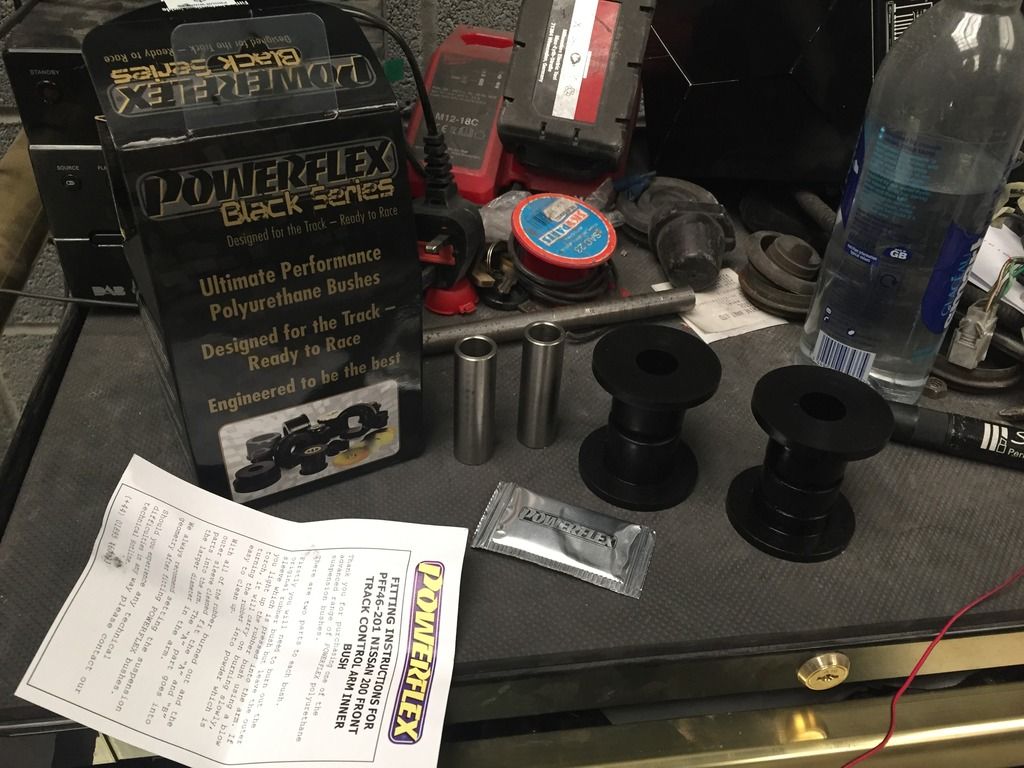

Now this is the bit I was dreading, ordering up the numerous AN/JIC fittings I need. So I began by creating a rough list of what I need;

I few friends of mine used Torques UK to get their AN fittings, and they appear to be good quality so dropped them an email. So this lot promptly turned up, and I was somehow £400 lighter (Yup, four-hundred!!!!) But they’re so pretty :wack:  The guy at Torques was super helpful, recommending me which fuel filter to go with as I wont be using the generic Z32 type, as I am now using a billet AN6 high-flow fuel filter after the Bosch 044.  I cant deny how pretty these things are, they kind of make the build step up a notch, plus they all have a pretty important job, so quality is an important factor here.  AN4 Turbo feed;    So whilst I was fascinated with these little fittings, I got some fresh LCA bushes from Driftworks, opting for the Powerflex Black Series due to being a harder compound.  To finish off the front end, I sourced a pair of Voodoo13 front tension rods from the states, something I can honestly say is that the quality of these arms are second to none.  At this point, I had finally dropped my bellhousing was off to be machined which was back the next day. After a quick steam wash to remove the small bits of swarf, it was ready to go back on.   Front cover before;  After;  Attempting this myself wasn’t the most fun of tasks, trying to keep the box still whilst ensuring the bellhousing goes on straight!  And before long it was all done. Kinda nervous about it leaking as it’ll be an engine out job, but I used a decent sealant, and made sure both mating surfaces were super clean and degreased, so fingers crossed!  This then means I can tackle the release bearing and sleeve setup. The conversion uses the Z33 fork and retaining clip, combined with an SR release bearing and carrier setup. Z33 setup;  New “Hybrid” combination;  An annoying thing with the gearbox was that the shifter had a slightly damaged thread, meaning my fancy gear knob would screw on. Not to worry, means I can get the good old tap set out and clean it up.  (Is it wrong that I enjoyed cleaning a thread haha?!) (Is it wrong that I enjoyed cleaning a thread haha?!) Now I can finally put the Powered by Max shifter on    Whilst the engine was out of the car, something I wanted to change was the fact my downpipe setup would’ve used bolts to fix it to the exhaust housing. This didn’t really fill me with confidence (It was my fault as I never put any studs in the exhaust housing), so grabbed some manifold studs and locking nuts from H-Dev, which look 10x better than a generic stainless bolt. Hopefully combined with Nord-Lock washers this should hold everything nice and tight! Whilst I was there, I quickly swapped the nyloc’s used on the manifold-turbo flange in favour of more lock-nuts. Hopefully, this again will reduce my chance of the nuts coming loose in the near future, whenever the car does actually start up and run.  I began to make my first AN line, which was the oil feed line. I read the smaller the fitting, the easier it is, so AN4 sounded perfect. Followed a guide online for the PTFE fittings and I’d like to say everything went well, but time will tell whether they leak or not    Next up was the AN8 line between the fuel pump and the swirl pot;  It’d be rude not to throw the Equips on the rear to check the level of fitment, because fitment is the number one priority! :wack:  I quickly disassemble the clutch in order to bolt the flywheel and pressure plate on to check the release bearing and carrier is the correct size. The Twin Plate is gorgeous, wish I could just layer each plate in a frame as start at the forever, but that’d mean not driving, so onwards we go.  And the fork sat like this with the bearing up against the fingers of the pressure plate;  Not good! Its almost bottoms out the hole on the gearbox, let alone the travel of the slave. So time to take a step back and have a think, which is kinda hard when this is sat in front of you     |

|

|

|

|

|

#47 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

So, the front windows were pretty beat up so I decided to go down the Polycarbonate route like I have with the rear. After a couple of weeks waiting for them to be made, they finally turned up;

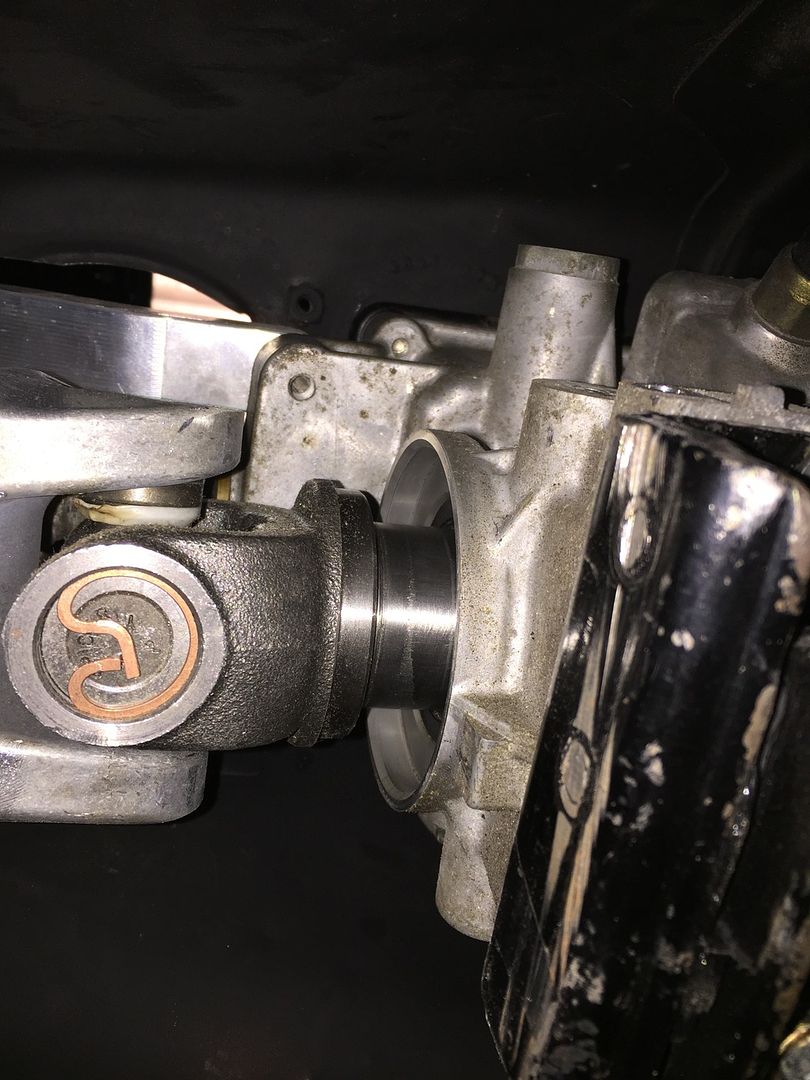

I spoke to a few people regarding how to mount them, with some people just wedging them up against the door, and some utilizing the existing runners. I went for the latter option, so first things first I got the old window in order to pinch the fixing and mark up their positions.    Adjusting them to fit perfectly was a ball ache, as I tried to make them sit under the original trim. 9/10 they sit perfectly with an odd time where they don’t sit flush. Those with a keen eye will see the windows have end plates, something Plastics4Performance offer to help reduce any flex in the windows. When you see cars competing with plastic windows, seeing them distort under movement always looks horrible in my opinion, so anything to avoid this is welcome in my book. It wasn’t before long until the other side was done. I’m stoked with the outcome, and so happy with the slider. In regards to the sliders, I opted for those with a 15* angle, which I feel suit the lines of an S-body so much nicer, and doesn’t make it look like a serious track car, after all, style is everything   Up next was something I’ve seen a few variations of, which most people will be familiar of the Nismo Powerbrace. Supposedly, bracing the front tension rod brackets will improve the responsiveness and stability of the front end. It just so happens a friend of mine is a welder by trade, who makes things on the side for his and other peoples’ drift cars. Usually the brackets are welded in situ, whereas we opted to take measurements and drop the brackets off to him. However, a simple type in my measurements meant the first go at the brace didn’t exactly fit. It was such a stupid mistake on my behalf I was kicking myself, but Mocock was a true gent and offered to cut apart the brace and get everything square as it should be, what a hero! Early stages;  Finished Brace and Zinc Coated;   When I found out the measurements I sent were ever so slightly wrong and it didn’t quite fit   All back from being re-done and quickly sprayed to protect any welds that didn’t have any zinc coating on;   And finally all fitted up as it should  Cant believe how good it looks with the engine bay colour, and cant wait to see what difference it’ll make to the front end. Cant believe how good it looks with the engine bay colour, and cant wait to see what difference it’ll make to the front end. Whilst this was happening, I chose to get the front subframe and lower control arms zinc coated in order to protect them against the elements.  Quickly sprayed the subframe to match the brace, and quickly bolted the steering rack on after a quick clean.  Whilst all this was happening, I bought a brand new OEM Z33 slave cylinder from the states. There are quite a few OE cylinders online, but for the sake of an extra £10 or so, the better quality OEM slave was a no brainer.   So whilst I was waiting on other things, I ordered up some Aquaseal Mbond 395 bonding adhesive/sealant, something that Plastics4Performace recommend as it is solvent free, which wont attach the polycarbonate. Oh and its formulated for the marine industry to survive harsh vibrations, something thatll suit an SR20 with uprated engine mounts then  :wack: :wack: - - - Updated - - - Cue 24hours later;     I began to split the 2 pairs of Z32 rear callipers in preparation of their rebuild. Whilst one pair came off my old car which I knew worked fine, and the other pair were supposedly fine, for the sake of a few hours work, a freshen up will do no harm at all.  I spotted one of the caliper has a slight tear in the dust seal, so cant imagine it would’ve have been long until water would’ve found its way in and begin to rust the insides. Who said Dual Caliper setups are fun?!  Cleaned up the calipers, and gave them a quick lick of paint (Black to match the front and to keep the dual caliper setup subtle)   Ive got to say a huge thanks to Bigg Red for providing the seal kits, grease, fresh bleed nipples and top service. The whole kit went back together pretty flawlessly, which hopefully means they will work as they should  So back to the gearbox drama surrounding the fork positioning. I quickly marked up the fork to see how it sat again. And then added the slave for good measure.   There’s no way in hell that this setup would work, as the fork would physically hit the gearbox bellhousing before fully disengaging the clutch. So back to the drawing board! So to cheer myself up, and went and grabbed myself a torque wrench, something I’ve never owned, and given the flywheel torque setting, its not something I really want to chance.  After finally learning how to set the damn thing up, it’s a pretty nifty little tool to be honest. With help from a friend, it wasn’t long until the clutch was on, and all torqued up to OS Giken and ARP’s recommended torque settings.  |

|

|

|

|

|

#48 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

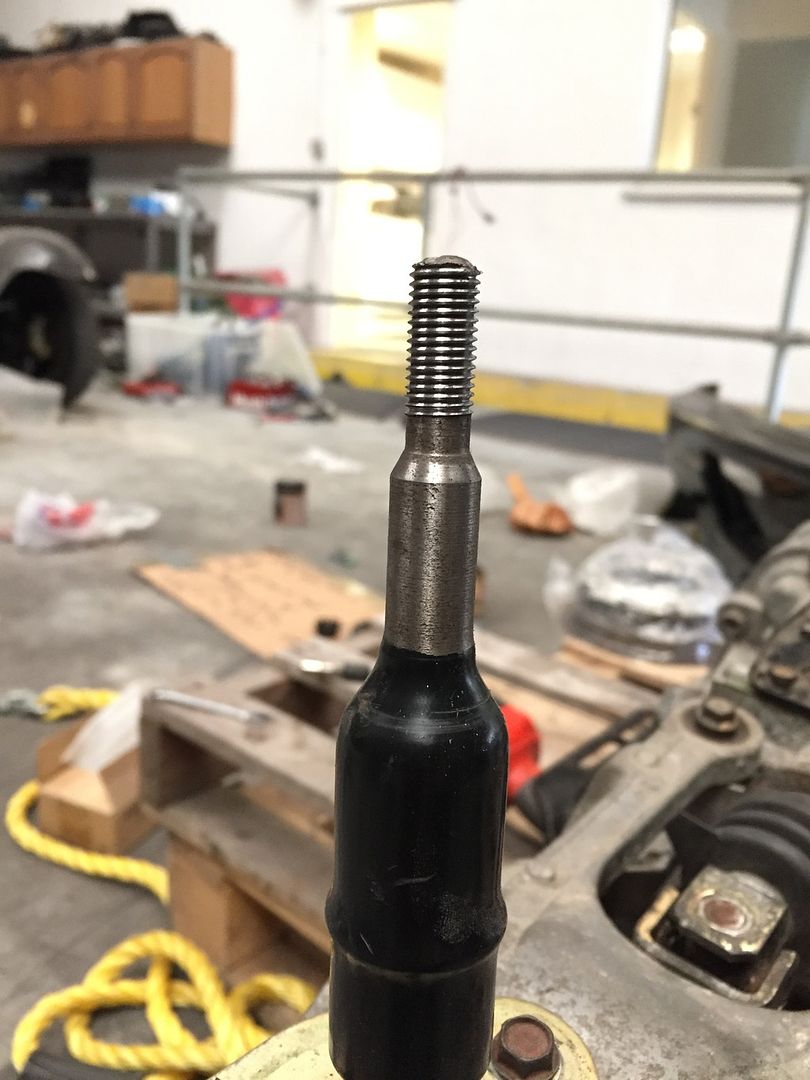

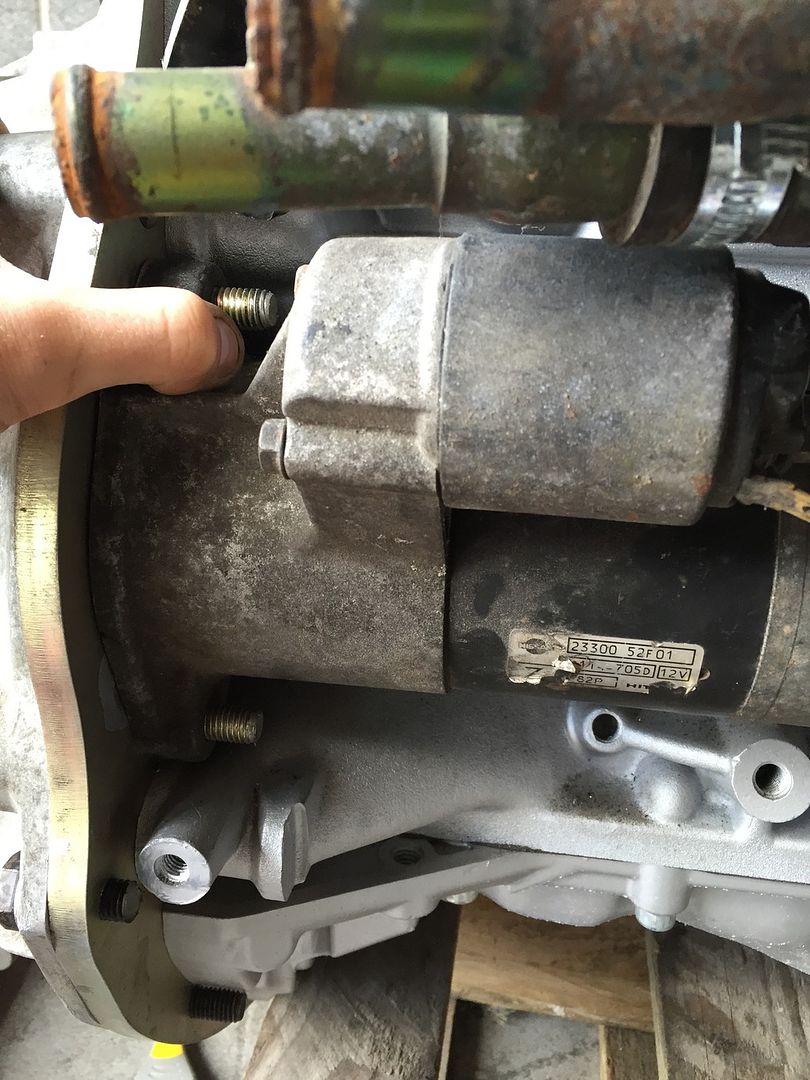

What with all the problems on my car, I’ve managed to make my dad become interested in his again, which in my opinion is nice to work on another car apart from my own.

I then got bored, and after an hour or two this kinda happened;  Hopefully the plans are to ditch the Rover V8 that’s in the hot rod now, in favour of something more spicy from the states. I decided to have another go at the release bearing issue, where I gave RB Motorsport a quick call as they’re the UK OS Giken dealers. After doing some measurements it seemed I needed a 32mm sleeve rather than a 16mm sleeve (I opted to follow the recommend sleeve for an SR box, as various people use the standard SR sleeve and bearing combination for their SR/Z33 conversion, albeit with regular 3-puk clutches). OS Giken only provide sleeves up to 28mm, leaving me 4mm short. Luckily enough, the 16mm sleeve I originally bought is actually a 12mm sleeve, with 2x 2mm washers to space the bearing in order to make up the difference, perfect! So the awesome guys at RB Motorsport sent me the sleeve which turned up yesterday. Initially I grabbed a few pictures for comparison purposes; 16mm Sleeve;  12mm Sleeve vs 28mm Sleeve;   Essentially a 32mm sleeve;   After a few trial and error runs of putting the release bearing sleeve/carrier and bearing together, and reinstalling the gearbox in order to determine whether or not I have OS Giken’s recommended clearance of 6-8mm between the bearing and the fingers of the pressure plate. This is because of the clutch being fresh, where the fingers will essentially expand once the clutch is bedded in. After a few combinations, it turned out the 28mm sleeve gave me around 7.5/8mm travel, which getting the desired travel is an achievement in itself!  - - - Updated - - - Another concern was that the OS Giken manual state that the front cover of the gearbox needs to be “trimmed” 4mm, which had gotten me a bit worred as I’ve already sealed the front cover to the gearbox. After speaking to a friend who has a lot more knowledge on clutches than me, we came to the conclusion that if there isn’t contact now, then there wont ever be contact when the springs are depressed, phew! This is because the “snout” of the front cover doesn’t enter the fingers of pressure plate, which will essentially contract as the clutch is depressed/ Given the o/d of the snout is less than the i/d of the fingers, and that the fact the snout is a few mm away from entering the fingers, in theory they should never meet or cause any issues. (Saying that, ive probably just jynx’d myself and will have to eat my own words in the future lol!)  Hopefully this means all that’s needed for the conversion is to shorten the shifter linkage which should be a relatively straight forward job for a friend who can weld. Another meticulous job was trimming the gearbox bolts down, as the bolts I was given with the adapter plate were for an S15 flywheel setup, which doesn’t need the bellhousing machines. Nothing 10 minutes with a grinder couldn’t sort out though…  Something else the Protuner adapter plate requires is the thread of the starter motor to be drilled out. For me, this is one of the key points of Protuner’s plate, as the adapter plate has tig welded studs for the starter motor, whereas others on the market require the gearbox off in order to access the bolt heads from behind. So whilst my old starter became scrap due to a snapped solenoid, I thought it’d be best to have a quick go on that before my another fully working starter motor turns up.   Turns out it’s a pretty simple modification to make  |

|

|

|

|

|

#49 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

I forgot to mention earlier than upon installing fresh balljoints into my front LCA’s, it appears the balljoint hole may have stretched slightly somehow, meaning they are essentially scrap as the balljoint could be pushed in and span by hand. After seeing current prices of standard S14 LCA’s, and then the cost of extending them 20mm to mimic my old ones, it just didn’t make sense to me. I’ve decided to sell my new polybushes and tensions rods and go down a different route.

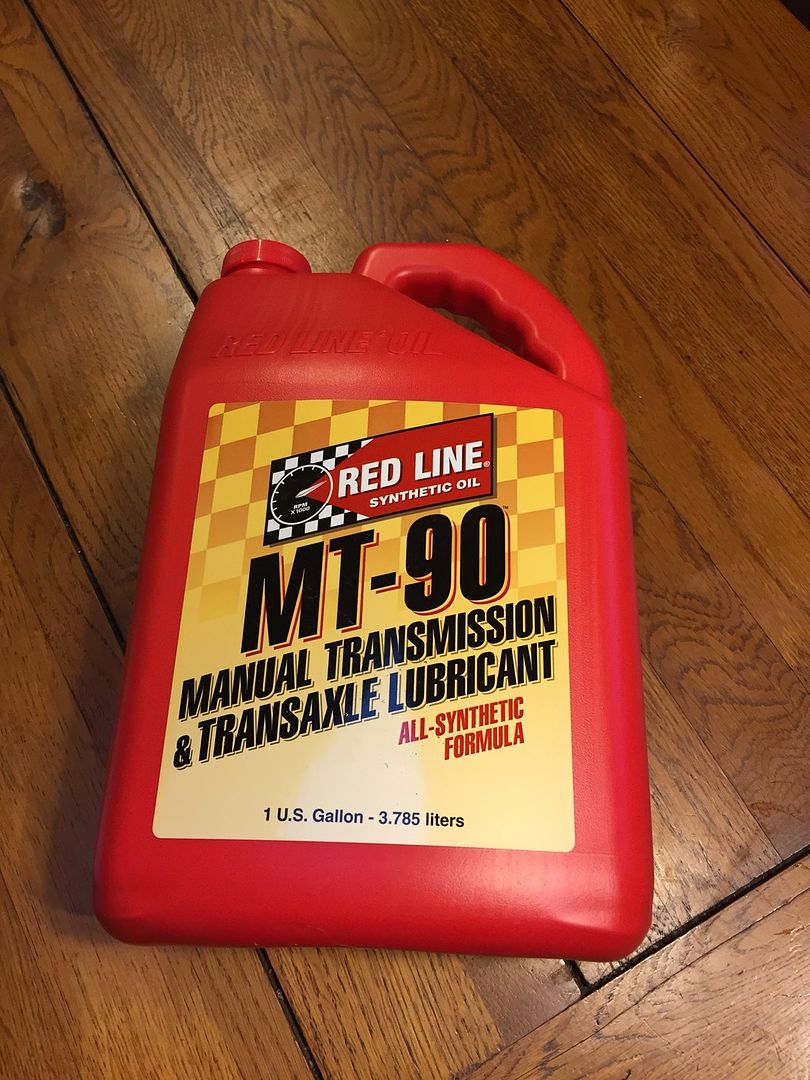

So a friend ordered me a pair of S14 LCA’s from Powered by Max, and by god they are phenomenal! As with all of my other Powered by Max stuff, the level of quality is insane.     I only quickly put one side on, as today’s job is to go down to the car and get them adjusted to how I want and hopefully get the front end bolted up for good  Inside that package was another package, this time from Mazworx!  Billet fuel rail;   ID1000 Injectors;  Shouldn’t be too long until the engine is the car, maybe that’s wishful thinking but I’d like to think that achievable  I went down to set the Powered by Max LCA's up, as I wanted to run them at their maximum length to try and mimic my old LCA's. Slapping all of this together was pretty straight forward, just following PBM's recommendation for the amount of thread engagement, then it was just a case of reinstalling the steering rods and ends and brakes. So after a couple of hours, it was finally on the floor! Ideally I wanted to keep the car in the air until the engine goes in, but I got a bit excited and had to lower it onto the floor to see the outcome :wack: This picture doesnt do much justice of how long the front subframe is, nor how low the car is. My old 13 was pretty low, and this was always going to be lower but its literally too low haha! The front wheels sit on the upper arch, so raising it around an inch is on the cards, but thats a job for Monday.     (Ignore the silly camber, I left the top mounts set to full negative camber, so i'll try and dial a fair bit out!) And odd thing was that my front was toe'ing out massively, I'm putting this down to the Geometers as the mounting point on the hub is probably different, and the extra 5mm track the PBM LCA's have given me, as they are now essentially S14 LCA's +25mm, instead of the +20mm my old setup used to run.)   The rear fitment is so good though! No spacers too   So today I'm hoping me and a friend can sort out the shifter linkage on the gearbox as it needs to be shortened, and then it should be a case of getting some gearbox oil and then the engine and gearbox SHOUD be ready to drop into the car. Wish me luck  |

|

|

|

|

|

#50 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

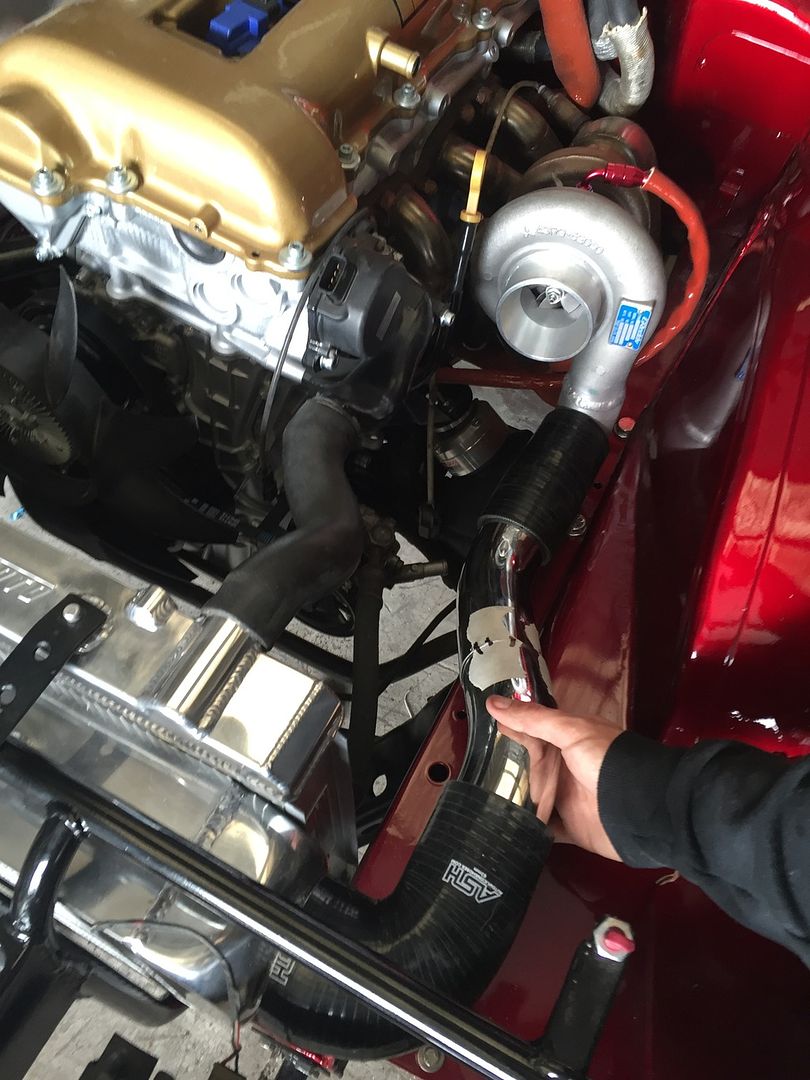

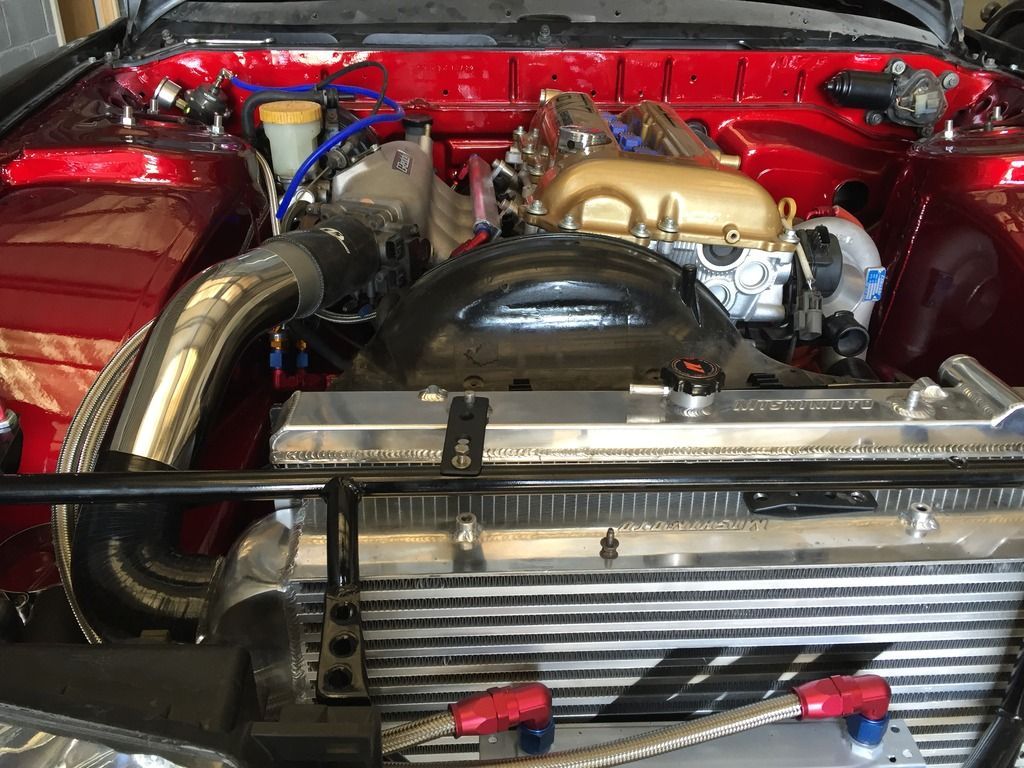

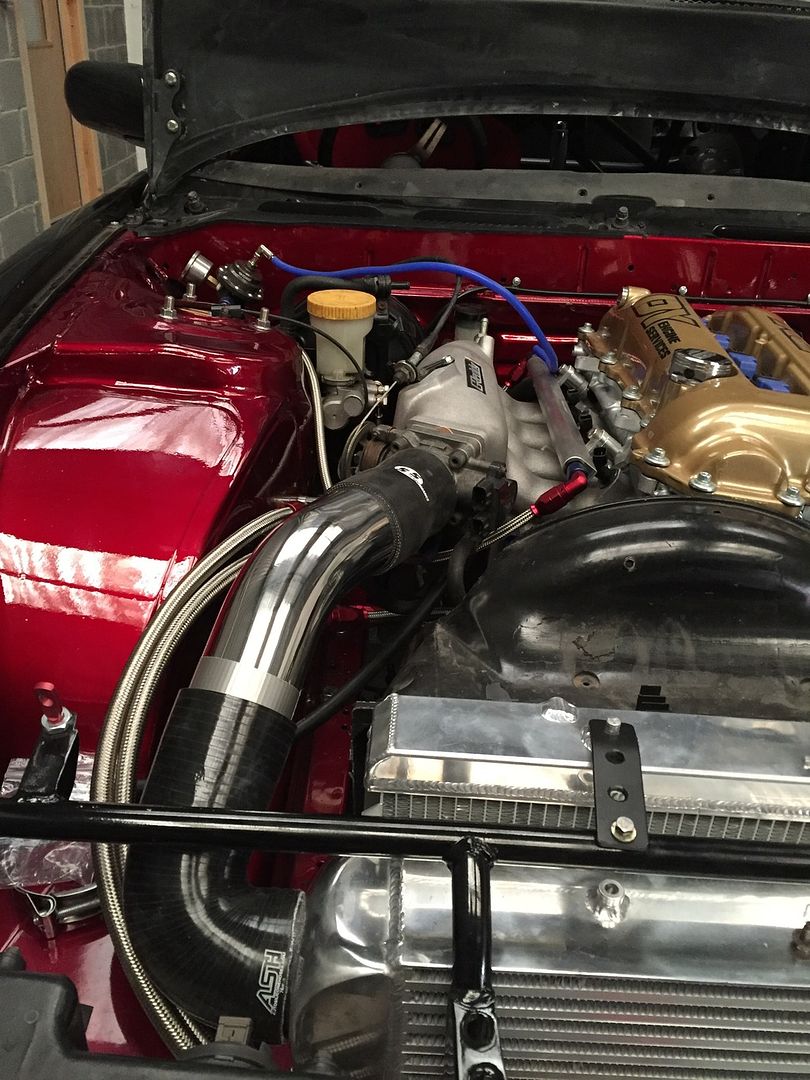

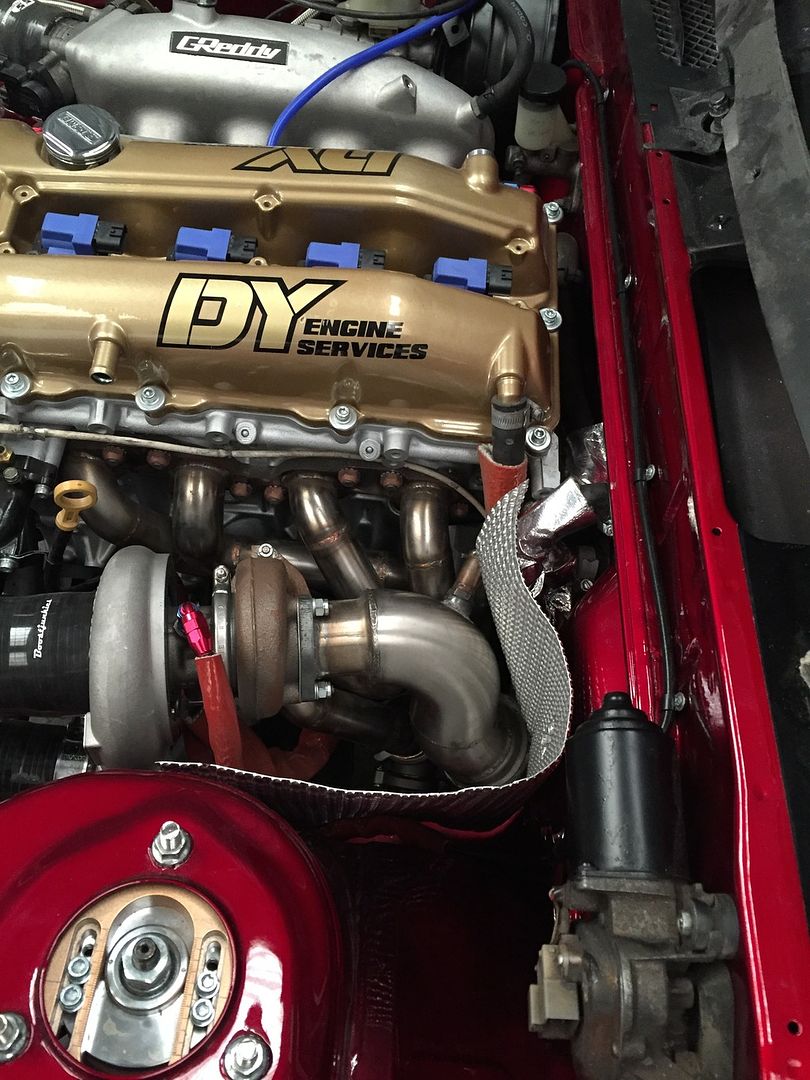

So since it was back on all four's with a ridiculous ride height, I couldn't stop taking pictures. I wish I could keep it at the height it was, but its not practical (read that as usable, the car would even move as the upper arch was just sat on the tyre!)

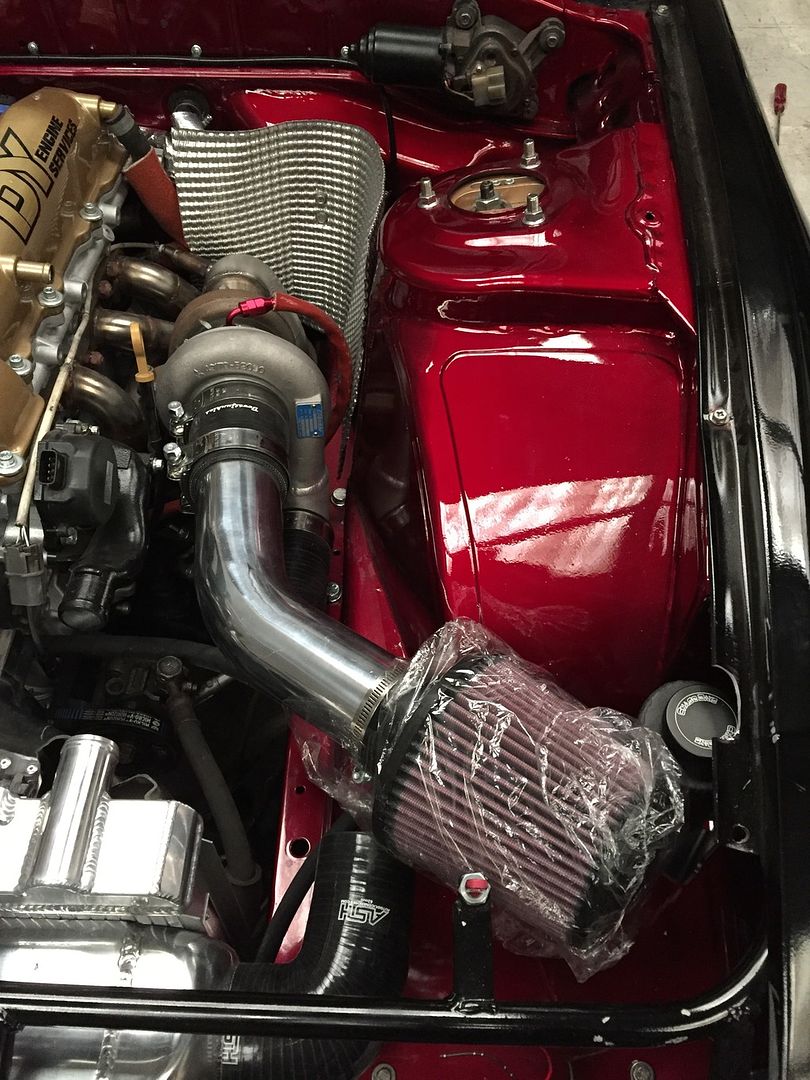

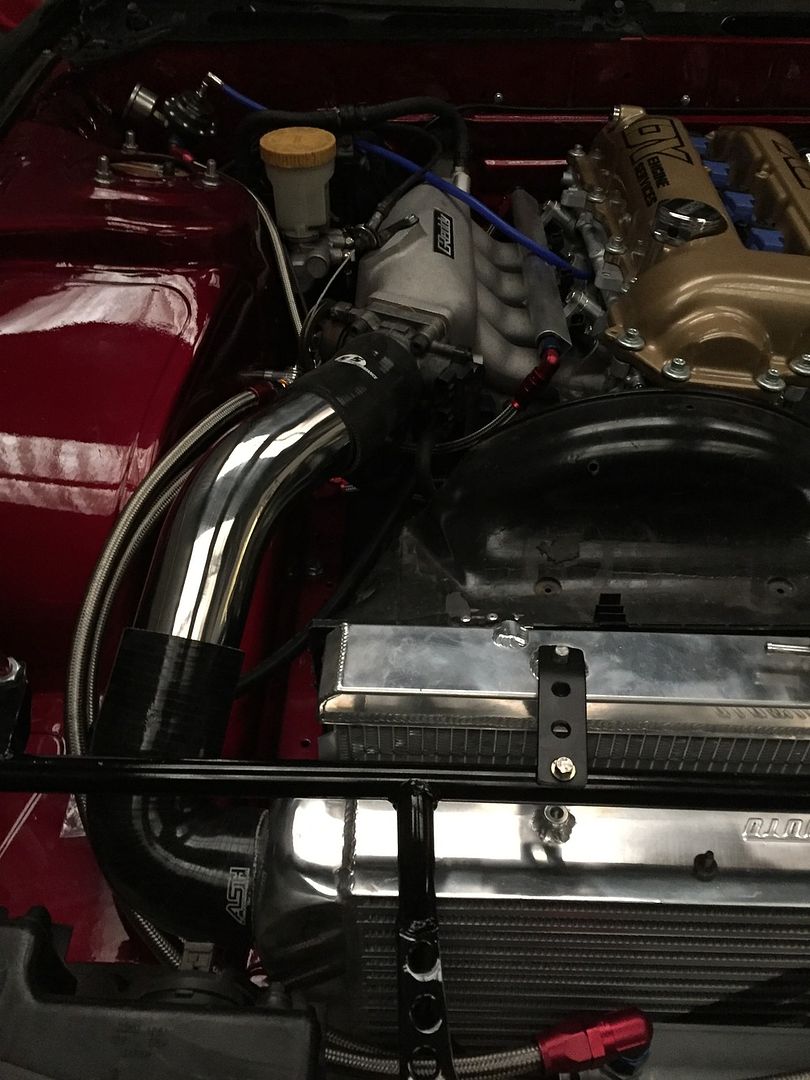

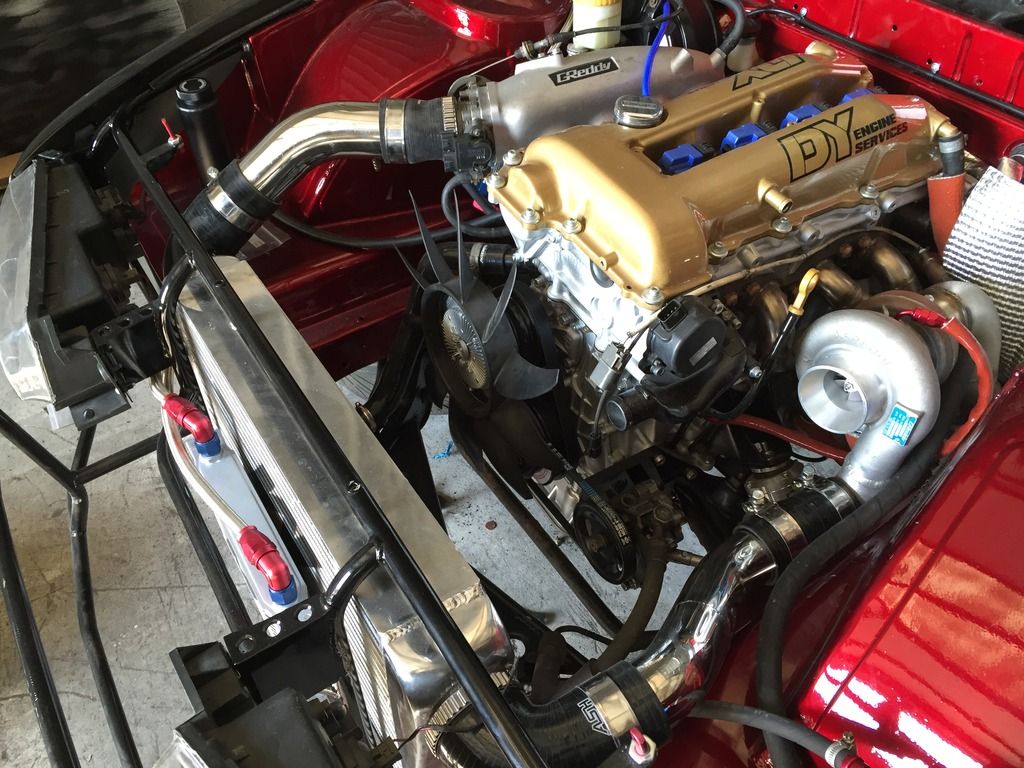

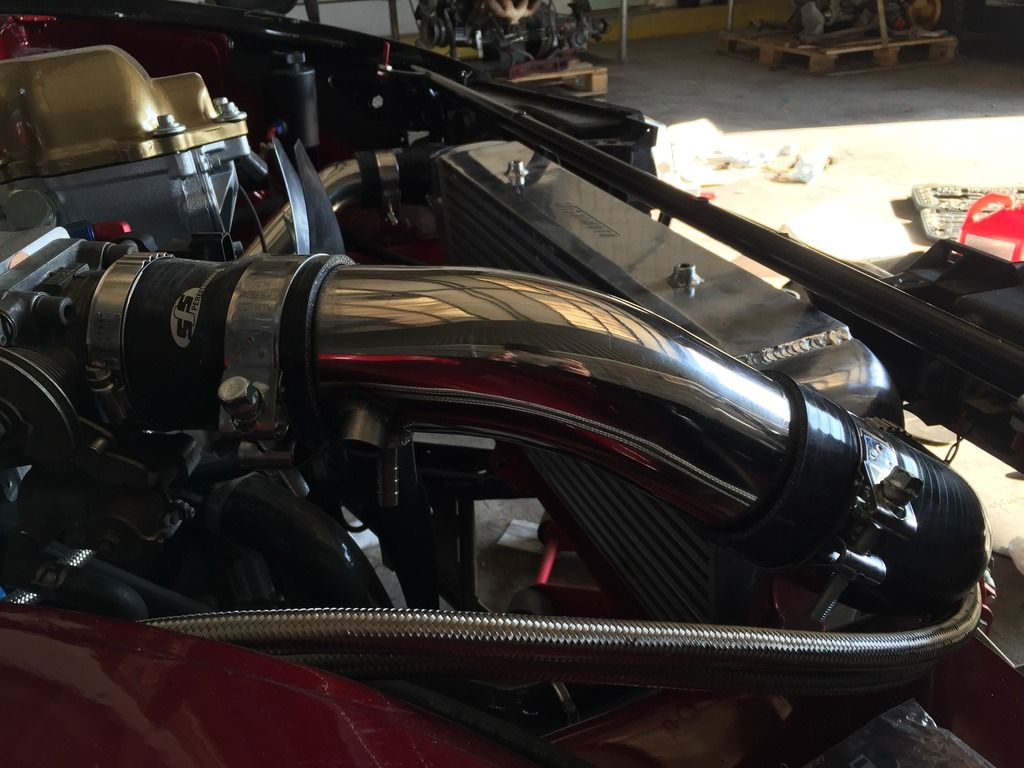

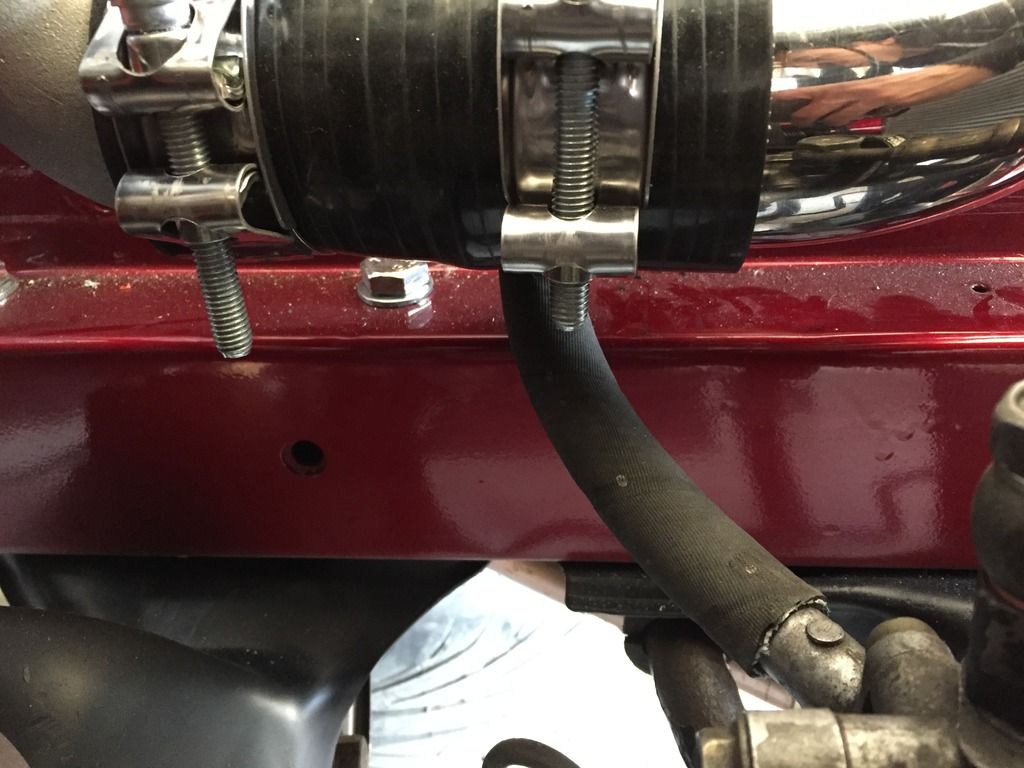

After lifting the Z33 box into the back of my car by myself, it was time to quickly pop to a friends unit, where a friend offered some welding the shifter linkage to meet the new shorter Mazworx shifter. In theory this should be straight forward, cut the rod between either mounting points to make it as physically short as possible, weld it together and happy days. And it was exactly that! After the linkage was cut, a few tacks were laid down and it just so happened to be that the first attempt lined up perfectly, all 6 gears plus reverse would engage. (I was having issues with the standard adjustment plate on top on the stock shifter, as this is supposedly meant to restrict movement in the shifter from going past 5th and 6th gear. Thankfully, the new Mazworx adjuster solved this instantaneously to me relief! So now the box works exactly as it should  ) )Now it was time to reassemble the box, bolt it back to the engine and get the engine ready to go in! I was going to wait until I dropped the gearbox oil in as I was a bit worried about accessing the fill plug once the engine is in. Having spoken to a friend with an SR/Z33 conversion, he assured me its doable with a suction pump  The reason why a tubular front is so useful :smokin:   After 5 minutes with a friends help and the worlds best engine crane, it was almost in. (The straps look a bit messy, but I always run a single primary strap to do the lifting, with another as a precaution should the first snap, which is unlikely due to the loads they are built to take. Better safe than sorry eh.. )  Once it was in, I couldn't help but stand in amazement for about 5/10minutes. I was pretty overwhelmed with how well everything works together, and the fact I'm so so glad I went with the Candy Apple Red engine bay over the gold I originally first had in my mind! We did come across a problem with the Collins Performance gearbox mount however, even though it fitted fine when the car was with Huxley getting the exhaust work done. After looking at the mount, I could see the marks from the bolts were at their maximum adjustment, and since then I've had the bell housing machined to accommodate the adapter plate. So a quick bit of thinking meant 2x 12mm holes were drilled slightly more forward, both of which lined up exactly, albeit with a little bit of enlarging to make sure the bolts go in straight. Sadly, I didn't get any pictures of this so more of a heads up to anyone reading who follows in my footsteps regarding the SR/Z33 conversion.   Quickly threw the tubular slam panel back on, as well as the Mishimoto oil cooler, intercooler and rad :smokin:     Whilst the engine was out, we quickly installed the Mazworx fuel rail and ID1000cc injectors :smokin: Thankfully, these seem to fit as they should which was a relief, considering how the standard rail did want to fit. But i suppose this fuel rail has been tried and tested by Mazworx on the Greddy inlet :roll eyes:   Ignore the front fitting on the fuel rail, I threw that on just to close of the fuel rail. Mazworx's kit only comes with one AN6 fitting, and one blanking orb/plug. I can only guess this is because they assume you will fit the standard fuel pressure regulator? Who knows, i'll measure up the threads and grab an AN6 male fitting when I order the rest of the AN fittings for the fuel, power steering and oil cooler setups. When fitting the Mazworx Z33 relocated shifter, it was apparent I had to "trim" the trans tunnel a bit more than I already had. Its a bit fiddly getting it in, but I'm not expecting to be removing it anytime soon.  Im hoping to take my Bride down tomorrow to see how it feels, but like a friend said, the Z33 shifter "arcs" from side to side as you shift. It feels a bit weird, but with a bit of getting used to I'm sure it'll be just fine.  I did have a bit of a nightmare when fitting the shifter however, as I completely forgot to tighten up 7x 10mm bolts on a plate that covers the shifter/selector mechanism. I could have maybe gotten away with squeezing a spanner to reach the bolts with an SR box, but the sheer size of the Z33 box meant this was a no go  So I had to quickly remove the shifter and drop the gearbox mount to allow the box to pivot, and thankfully this was enough to reach, and tightness all 7 bolts with ease, phew! So I had to quickly remove the shifter and drop the gearbox mount to allow the box to pivot, and thankfully this was enough to reach, and tightness all 7 bolts with ease, phew!  |

|

|

|

|

|

#51 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

I started adjusting the front end setup today, which was mainly raising the front and beating the front arches to try and get some kind of clearance on lock. I wont know for sure what clearance will be until I get the castor setup, but smashing the inner arches can be quite therapeutic :wack:

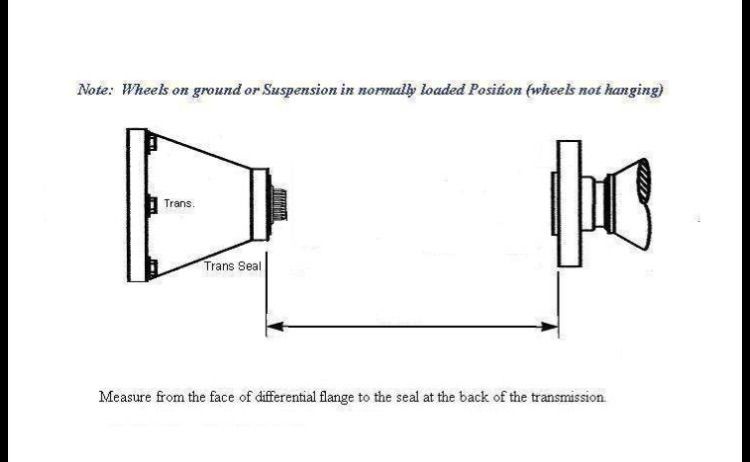

As you may notice, I also installed the brackets to try and stop the brake line away from getting caught   As today started off with quite nice weather, it'd be rude to not let the car see some daylight, and then proceed to find the largest hammer I have and "massage" the rear arches  I raised the rear a bit too, as it was sitting uneven with the drivers side tucking rim statically. Im hoping this ride height will still be pretty low and under compression it'll tuck rim    This is how the ride height sit as of tonight;  A few tweaks are still needed, as the drivers side sits lightly lower :wack: I did find a problem with the bonnet however, quite a common one it seems. The most rearward vent hit the top of the valve/rocker cover which is a right pain in the ass to be honest as it never did this when the engine was last in the car. I can only think its because of the Vibratechnic engines mounts being slightly larger than the Japspeed ones that were in the car beforehand. So my option are to either cut/trim a hole for the bonnet to close as it should, or possibly try to space the rear hinges to ease the angle the bonnet has to sit at. I'll try the latter tomorrow, even though I'm not a fan of raised bonnet, it may save cutting a hole in an expensive bonnet  So with the engine, gearbox and shifter all installed for what I hope to be the final time, I thought it would be a good idea to throw my seat in to see how the shifter feels. A friend of mine was saying about how much nicer it is with the shifter sitting a couple of inches further back, which I completely agree with! Im not the tallest of guys, but with my seat on my old settings (which is fairly low) the shifter feels like its in a much more natural position. After playing around with the shifter and handbrake again, I seriously can't wait to see how this feels out on track.    For those with a keen eye, you'll see I've had to raise the rear of the bonnet using 3 nuts/25mm ish. Even though the Vibratechnic engine mounts state they are the OEM height, I can't help but feel they are slightly bigger as the bonnet never used to foul the valve cover. Hey ho, I never used to like bonnet spacers in terms of aesthetics, but I suppose they depend on the car in question as it's slowly starting to grow on me...  In addition to raising the bonnet I still had to "trim" the bonnet which was something I really, really did not want to do.     Today's job was mainly about measuring the prop. Originally, I was sold on the idea of modifying the original 2-piece Nissan prop like a friend (Diamondsink) had done to his, albeit with a Z32 box. After spending a few hours online, I came to the decision to purchase a 1-piece aluminium prop from America, Shaftmasters more specifically. This was because the price differential isn't as much as you'd have thought, especially by the time I purchase a Carbon 350Z prop just to cut the metal yoke off, and then pay for somewhere to professionally cut and balance the new "hybrid" prop. I wasn't really confident on the idea of measuring the prop as its something I've never done before, but everyday is a learning day i suppose! Anyway, I got in contact with David @ Shaftmasters and he talked me through the measuring process with this simple diagram;  So firsts thing first was to get the car back in the air, yet again! But this time I need to make sure the car is loaded/suspension is compressed.  Shaftmaster's do offer an "S13 Non-ABS with Z33 Transmission" prop, but as I've machined the bell housing I wasn't really sure whether my measurements would be the same as theirs. But with a little bit of luck, my measurements came back at 1247/1248mm, which luckily enough is the same as their measurements! Worst case scenario was that the prop would be made to suit my setup, but having the same measurements did put my mind at ease somewhat. As for those intrigued how the Z33 box sits inside an S13 tunnel, here's what it looks like;  So thats me up to date for the moment. Ive ordered a few little parts up, one of which being yet more AN fittings! But hopefully this means I only have a few more to get in the due course of time when I need them. One of the issues I do have is mounting the Greddy/Grex/Trust sandwich plate due to the side of it, as I'd like for it to be mounted to the side of the front arches, but the size of the AN fittings and oil filter are making things a little bit more difficult than they should be. In my head I have the idea of mounting it vertically, so that the oil filter is positioned horizontally. (Similar to how they naturally sit on the SR20 block, albeit facing the opposite direction) |

|

|

|

|

|

#52 |

|

Leaky Injector

Join Date: Dec 2012

Location: Bristol, UK

Age: 30

Posts: 92

Trader Rating: (0)

Feedback Score: 0 reviews

|

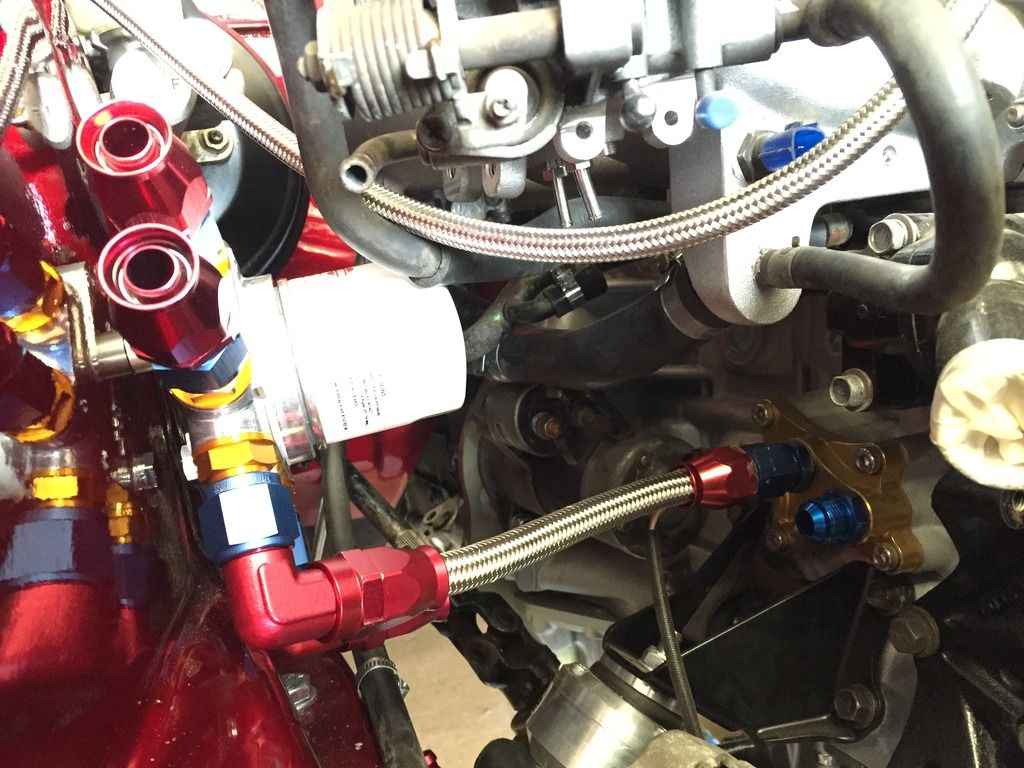

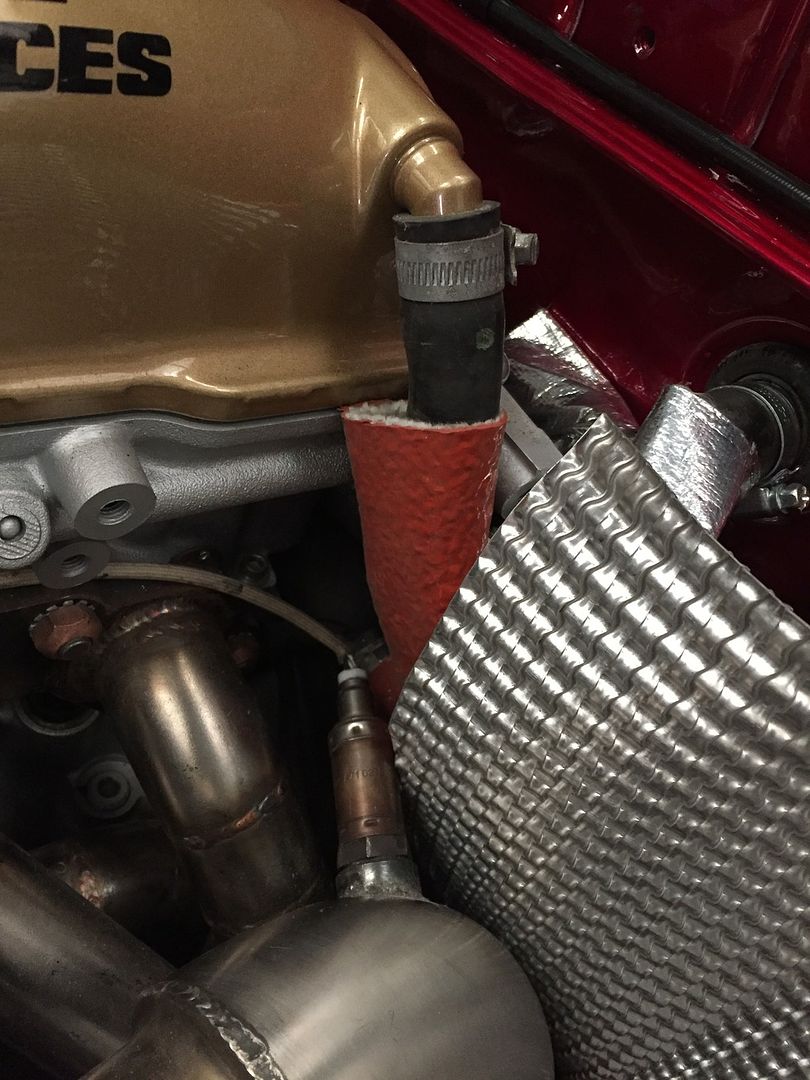

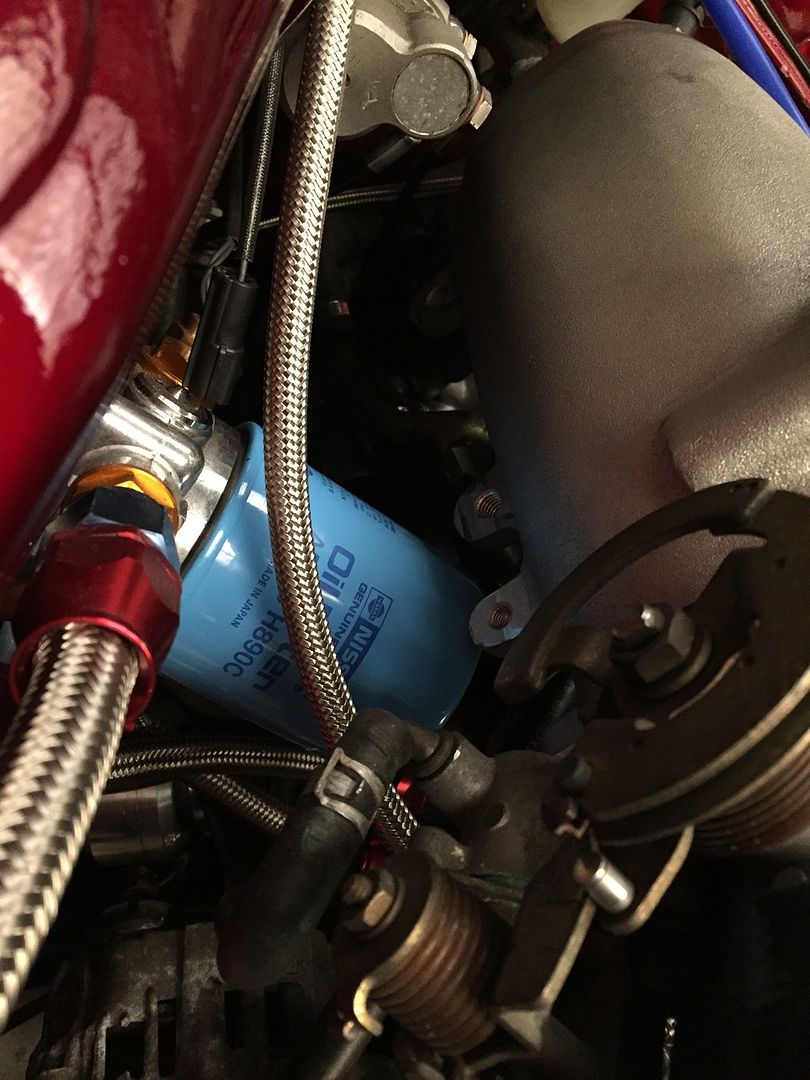

Ive been toying around with how to fit the Greddy/Trust oil filter relocation plate, as its quite bulky and with 4 AN fittings, it needs quite a bit of space around it. I wasn't keen on the idea of mounting the filter vertically upwards in case the filter doesn't have a one way valve(?) to stop any crap falling back into the oil. With this in mind, I want the filter to be mounted horizontally, similar to how they are naturally on the SR20, just facing the other way as I would like to mount the plate onto the front arch. So first things first was to order an oil filter so I can test a few locations. Thanks to Driftworks I grabbed 2 OEM filters, one being for the run in procedure, and the later for when the engine is ready to get wound up a bit.