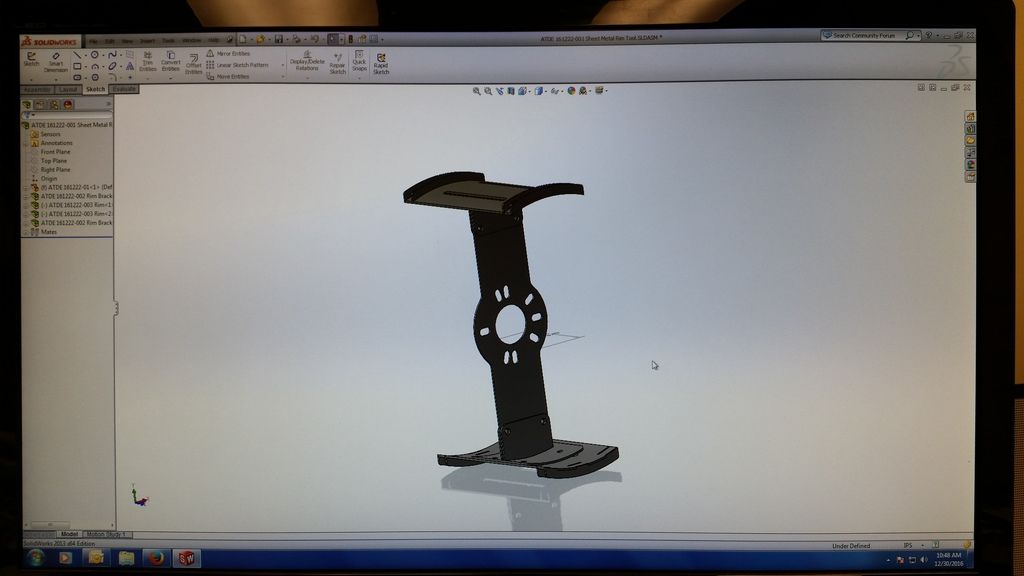

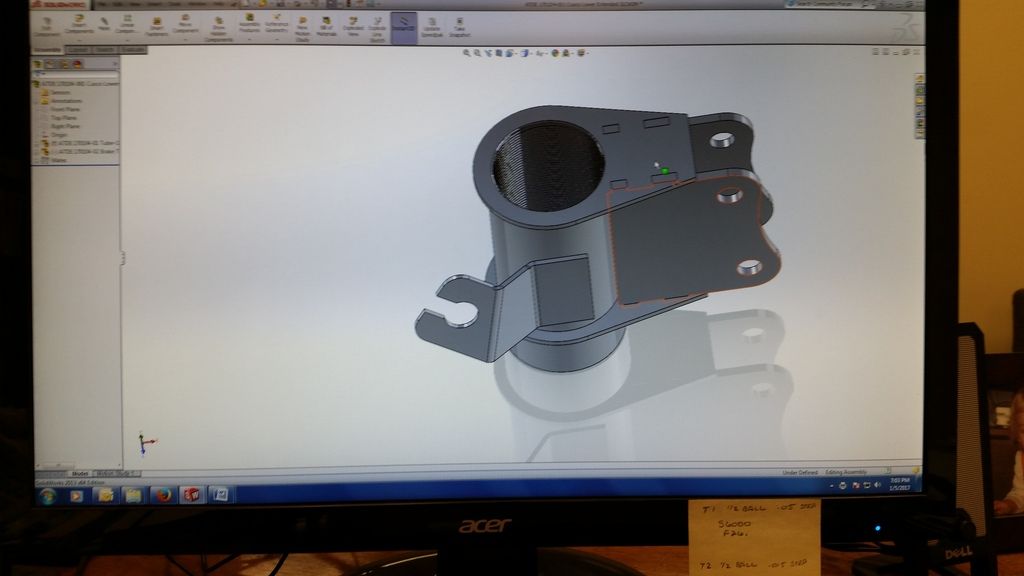

Here's a long update. Since the last post, I've been working on determining the proper offset for the front wheels, preparing for fender flares, and picked out some wheels. For the front wheel offset, I designed a wheel back space tool based on the aluminum ones that the pro-touring guys use. I designed mine in solidworks to be laser cut and fabricated to make it inexpensive and easy to build.

I made 10.5" and 11" "rim" sections with an inner lip to push the bead of the tire out to get a more accurate measurement. The 11" actually pushes the width of the tire carcass from around 11-5/8" to just barely under 12". I have the tire on the tool, mounted on the car with my camber set to about 2.5 degrees.

This is the first position I tried, spring removed, with minimal strut tube clearance, they actually seem to fit best. I still need to disconnect my sway bar to check tub clearance under compression, but I really like this position because the tire doesn't hit the bumper or the back of the wheel well. It also seems to get nearly as much steering angle as my current little 225's which impressed me.

I also tried it here, which gave enough strut clearance to instal the spring, but it seemed to lose clearance everywhere else when I turned the wheels. It hit the pinch weld in the back of the wheel well and a little bit of the bumper, I can trim either of those, but I'm also kind of wondering if that much extra scrub radius will be a bad thing. I'm thinking that I will try to get as close to the first position as possible, unless anyone fills me in that that much change in scrub radius is good for handling and driving feel. To maintain the position I want I plan to make extended strut ears, with between 1/2" to 1" of extension. The Cusco's are more difficult to use for clearance because they use a 3" ID spring, since they're inverted shocks, instead of a 2.5" which is standard for coilovers.

I have pieces laser cut for these too, I just need to pick up some DOM tube, weld it together and thread the inside. The 1" extension is shown in the model, I also had 1/2"+ ears made, I'm wishing I just would have done the full range and did 3/4"+ while I was at it for another option. I may make those later if I find that working best, or slot the holes on the 1"+ ears and make some offset washers.

I had some help from a good friend with a photoshop rendering of about what I'm going for with the finished project.

I started off with some JP Fiberglass Rocket Bunny style flares, but wasn't feeling all the body work for something that I might not want to keep on the car that long, its been a popular trend for a while and I'm not sure how much longer it's going to stay in favor. Plus I was hoping for the best on the knockoffs, but they were really mediocre at best, the fiberglass was thin and flexible, which is a positive on my book, but there were imperfections around the screw dimples and they aren't gel coated like I've seen on my other fiberglass parts. After seeing Masahiro's S13 I just couldn't get over the cleanliness of metal flares.

I'm not into the stance scene for my own car since I want grip and some drive ability, but I love the undeniably clean look and its the inspiration for the new direction on my body work.

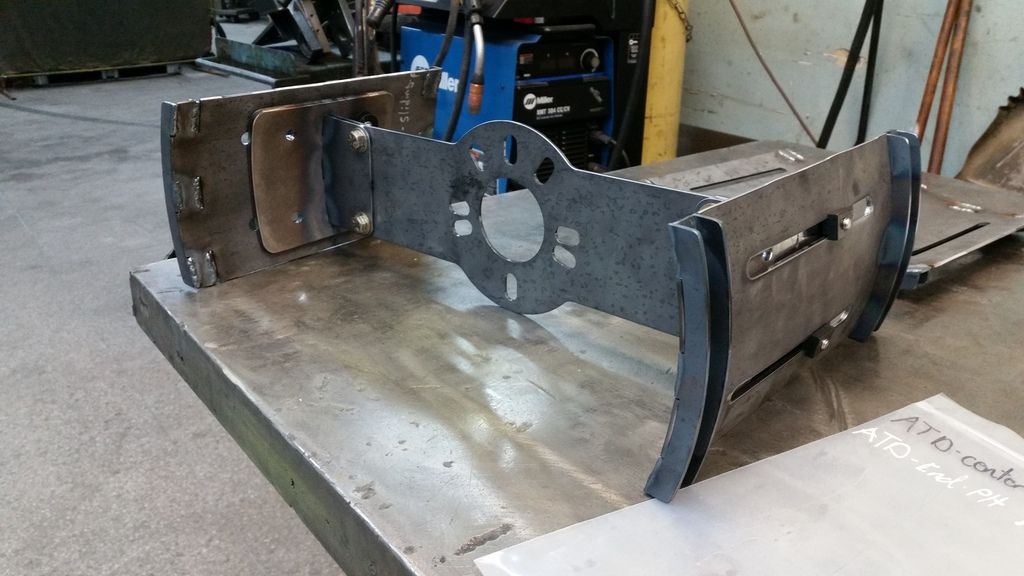

Since picking a direction, I've also been getting started on the preparations to make bucks for the flares. So far I've started with these holders.

I made them to hold the fender in the same position it sits on the car from MDF, this way it should make it a little easier to make the buck and keep the wheel opening from looking off, at least that's my thinking since I haven't made a sheet metal buck before. I also attempted to 3d scan them with photogramy (Visual SFM and Agisoft Photoscan) software.

It was really cool to see the whole room in 3d and it was pretty amazing what it could do, all things considered, but it has major limitations with smooth objects, the 3d model looked like it was made by a caveman with a hammer on a rock, so it wouldn't work for building off from.

For the wheels I had narrowed down my options to Enkei RPF1's, Work Rezax II, SSR SP3's, and I had searched some to find some used CCW Classics, and I stumbled across a set of used Forgeline GX3/GX3R's on Ebay. They're light, strong, I've seen a lot of positive feedback on them, I like the looks and I haven't seen a 240 with them, so I bought them.

They're 3pc with hidden fasteners, 18"x9" with 7" backspacing. The plan is to change the lips and barrels to get them to 11" wide and right now I'm estimating a 6" backspace (0 offset). I'm still working on picking out the colors I want to build them in. The faces most likely will be satin bronze, but I haven't decided on the lip color yet, I'm thinking either polished, high gloss/liquid/polished bronze, gloss black, or matte black.