Quote:

Originally Posted by drscooper

Goodness, Its nice to see another DYI thread thats as in detail as this. Keep up the good work itll feel great once you get it running. In for more updates.

|

Thanks, I appreciate the positive feedback. Here's another update, I'm trying to do about one a day until I catch up to my blog, then I'm going to update them both at the same time as I get more done.

When I put the engine back in it was pretty drama free, a little nerve racking with the fresh powder on the cross member and fresh paint on the firewall but there really weren't too many problems, aside from needing to get a bigger hammer because the tunnel wasn't beaten in far enough. I ended up getting a 2lb Nupla Drilling Hammer, it was the perfect tool for the job, the big Harbor Freight compthane just wasn't getting it done. A reminder for others, make sure to smash that tunnel in really good in for clearance, if there is any questions, hit it again.

I even got my wife in on the action this time. She was such a good sport, she took the usual first timer spot under the car to guide the tranny into the tunnel.

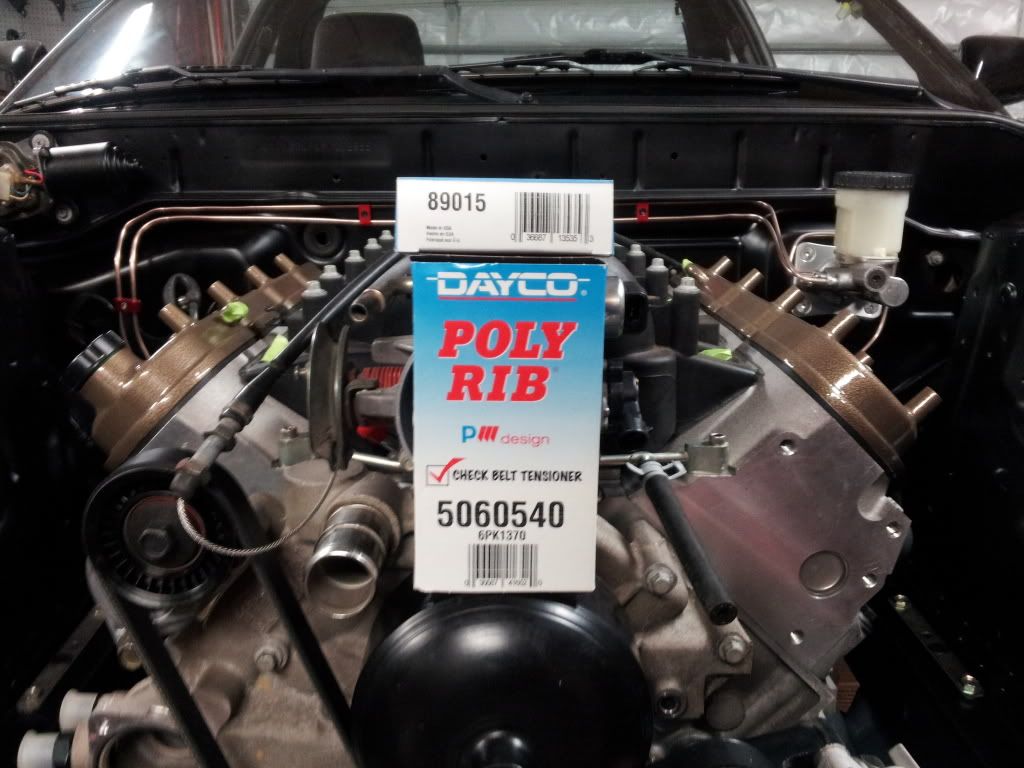

If you want to run no accessories and a 10% under drive pulley like I did, these are the parts you need to do it. You have to swap the smooth idler pulley on the alternator for a ribbed idler (same one used on the tensioner) Dayco p/n 89015. The belt that fit the best was a Dayco p/n 5060540 54" - 6 rib. One thing with this belt routing I had to do a little work on the alternator bracket. I had to countersink for flathead bolts.

Make sure to only countersink the sleeve so that it will still somewhat do its job and slide to the alternator.