Im Kinda new on these forums mostly cause i havnt posted much at all. But I had to post on this thread. LOVE all the work you guys did. hope you like mine too. This is the pix of my Cage construction among other things in the project. I copied and pasted this from my blog so I kinda worded it for anyone that could be reading it. Tell me what you think....this was my first time doing any serious fabrication work!

In this photo, i have removed most of the interior, next is the dash and carpeting.

Believe me, the dash was fun to remove. ahhh yes.

and now to remove this black tar looking stuff which is sound deadening material. or as i like to refer to it....Dead Weight.

Im going to use Dry Ice to remove this tar crap. it freezes it and makes it extremly easy to remove. great stuff!

and now to grind out the chassis seam sealer! this stuff is a messy pain! after i grinded top surface i used an acedline torch and scrapers to get the rest out of the crack. this way i can stitch weld the seams! (also notice the gas tank is removed, always remove this and the ECU before any welding on the car)

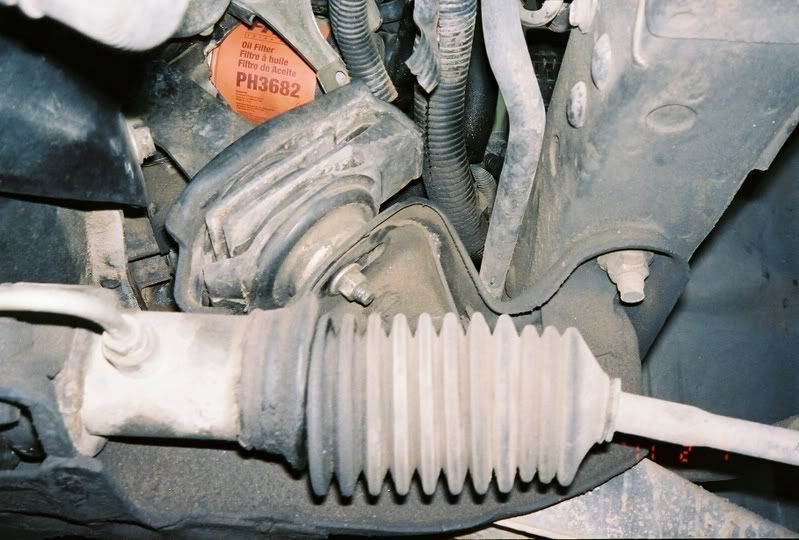

Ugh, that took a long time! ok now for something easy! stiffer engine and transmission mounts from MEGAN RACING JAPAN! They fit KA and SR. So when i find the sr front clip i want (i hope before end of april!) i can still use them!!!

first lift the car, and support the engine/transmission.....

here are the stock mounts....

and here are the MEGAN RACING mounts!

OK OK back to business! time to bend some Tubing for the Roll Cage! Im using 1.5" X .120" DOM Tubing. incase you dont know 1.5" is the outside diameter and .120" is the wall thickness.

drawing blueprints with measurments taken from the car, and using the bending die to find the tangent lines.

Time to start bending!!! (the dumbass next to the tubing bender isnt me, haha)

The Main Hoop is easy to bend! But the A Pillar down bars are the hardest! They are a compound bend! ahhh!

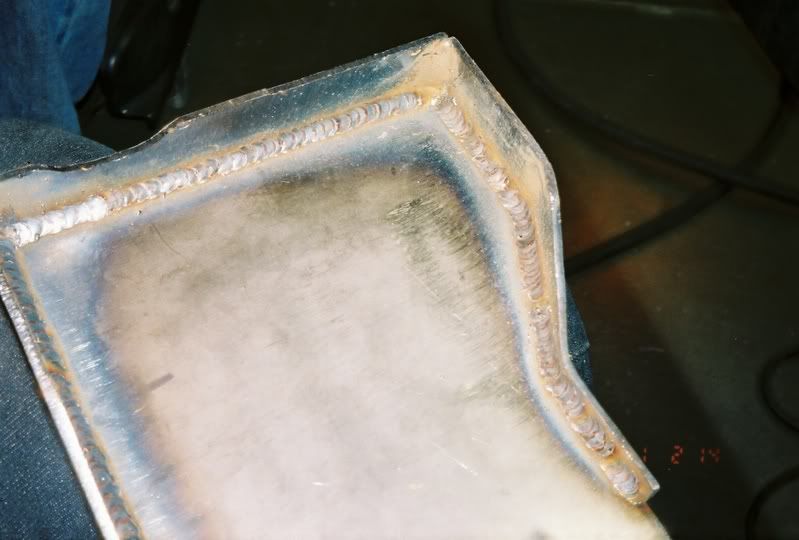

Okay, now its time to make the mounting plates for the main hoop. it needs to be mounted on a flat surface, so here we go!

and now to make the mounting plate to fit this spot perfectly!

does it fit? OH YES!

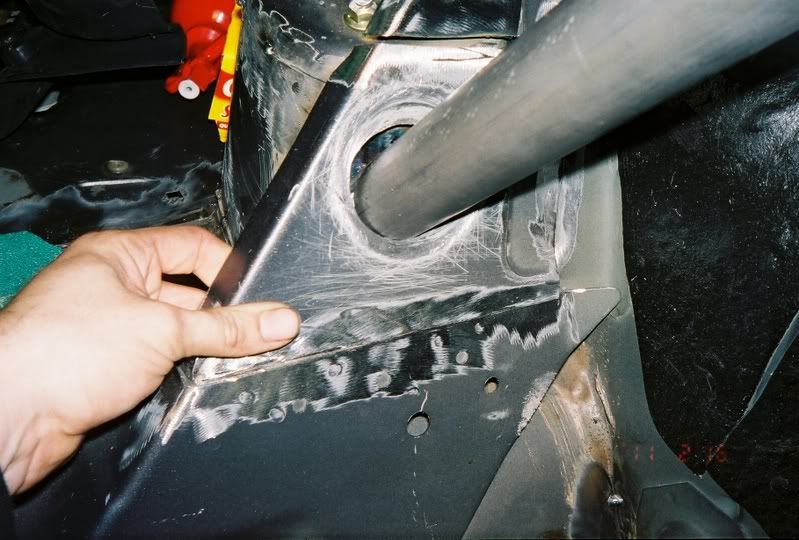

OK now to Do fitment of the main parts of the rollcage, and after some fine tuning, metal grinding and some positioning, im going to tack weld them in place. when i am happy with it, i will fully weld it all together!

ok now for the rear down bars, im taking them to the rear strut towers. and im going to use an exsisting hole to run them thru the chassis bracing. something like this...

Thats all the pix i have of this work right now. Ill have more up later. unfortunatly when the chassis was done and i was ready for the new engine the car got hit by a truck and now I have to start over. Next one should be better right?