Hi Zilvia !

I've been meaning to update this thread, I will be getting off mobile-social media for a while at least, and back to using the boards more. While it is nice to see everyones up-to-date builds on Instagram, its such a time waster for me and i think its progressed to that numbing point of mindless scrolling and the only way i feel not using it is quitting cold-turkey, pretty much like i did with Facebook. I'll still leave my page up and active but i just wont check it, if any.

----------------------------------------------------------------

Anyway, After the rear E-brake parts i pieced together and cv boots was accounted for, i dug into that job. the old boots were bad and definitely needed replaced.

And fuck the z32/q45/r32 rear drum e-brake assembly, holy good god !!

Went to a few end-of-year events and took some pictures of the car for what was a mild Christmas we had around PA...

-------------------------------------------------------------------------

Around the beginning of February 2021, I FINALLY received the new lips from Threepiece.us. (ORDERED JULY 4th/5th 2020) While I was happy to have them, I think they thought they were doing me a favor (because of how long it took) by polishing and drilling the hole for the valve-stem (which i didn't want, incase they didn't drill it the correct size, and i was going to have them all Chrome plated anyway). **Spoiler, I ended up polishing them all again

!!**

Since I had started prepping them taking them apart to clean the sealant off and clean/re-polish the hardware It was time...

TEST FIT !

I realized that the body was definitely going to need work to fit them. Buy wheels and fit the car to them... Good thing is, it was still going to be mild for my taste...

-------------------------------------------------

Another side project for the garage. I needed a new sandblaster that i could put bigger stuff into. Checking dimensions/options/mods of the bigger harbor freight model, i decided to make my own, I found the plans online and got some plywood.... It's roughly 22"x46" and the back is 30" tall. I also used some parts from the bench model I had (glass/frame, glove rings, lid latches).

Started with the box and legs.

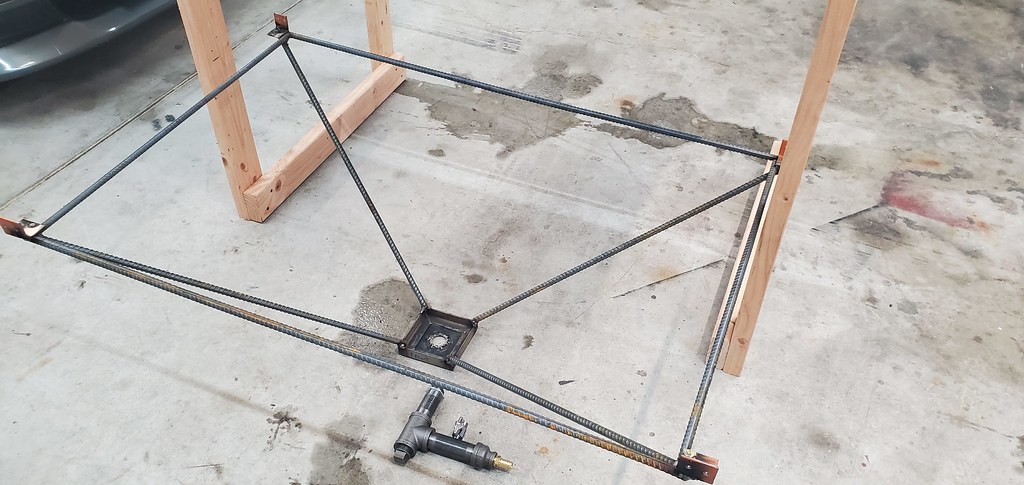

made the hopper out of rebar with the intent to line with sheet metal eventually, but the plywood works ok. just doesn't let the sand flow down quick enough sometimes. i might add a small electric motor with a counterweight to vibrate the sand down to the base as i blast.

this is the sand metering valve i made with plumbing parts. This is a common mod on the harbor-freight model. i tack welded an electrical conduit nut to the hopper base inside and the other on the bottom threads locks it in place. the 1/2" ball valve meters the sand flow to the gun for performance

sealed it up with some all weather-flexible black gutter sealant.

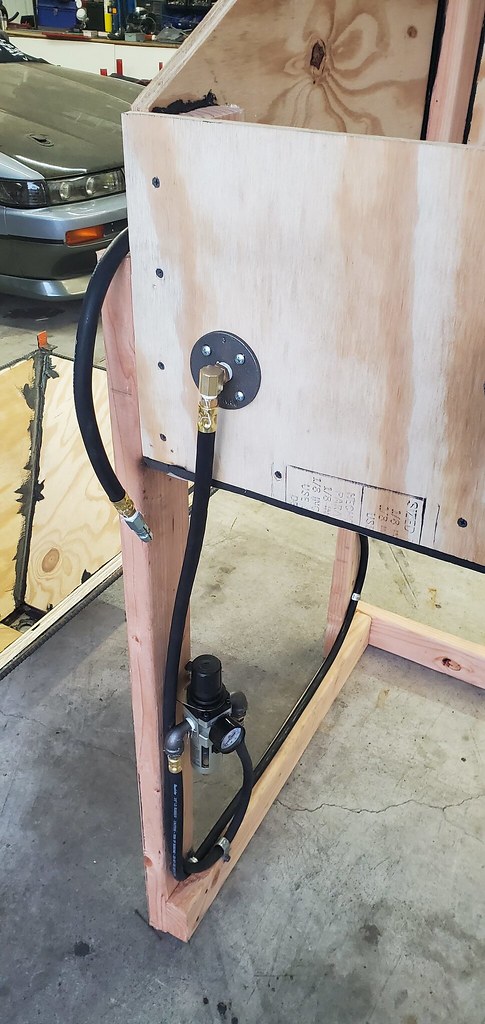

Added the air dryer/regulator on a leg+ routed the air line (3/8" coupler/line from the wall outlet to keep good flow)

I also saw a popular HF mod was a cyclone dust collector, I found stuff to make one that i just attach my shop-vac hose to.. Its some buckets and pvc fittings. It reduces the dust into the vacuum by like 90%, like a pre-filter..

Cant forget to bend up the baffle to the hose outlet.

Next up, was the air supply to the gun. I wanted a foot air-control and a v-shaped gun, tons of other different styles, I like the feel of the v-style in my hand when blasting. I ended up making this...

Its an electric solenoid valve that opens when i push momentary switch, which is on this..

It's a popular design and i can get different boron/ceramic nozzles on amazon/ebay for it.

Put some glass flood lights in some sealed sockets for light.

-----------------------------------------------------

Having the compressor running/filling constantly (but to exceed the duty cycle too much) i made this muffler with some wood/duct-work/iron pipe/fittings. It actually made it significantly quieter.

Ended up just making a cabinet for it and put rockwool inside for sound and a box-fan on top to pull the heat out when running.

-----------------------------------------------------

I ended up blasting the wheel faces and my lug nuts to powder coat them. I made the stand to hold the faces while I powdered them and then for after they baked and a piece to hold the lug nuts.

I had like 20 swatches sent to me for my faces and for the RSX/Volk faces to pick out from. The powder for the Panasport faces is Heavy Silver from Prismatic Powders. They also have clear powder on them, when i only baked the silver it was slightly textured, I wanted the depth/gloss and protection from the clear and it made them look really nice!!

Fresh re-built, polished and sealed.

---------------------------------------------------------------------

To Be Continued ---->